Accumat

DESCRIPTION:

Bartending requires many types of responsibilities other than just mixing and serving drinks. Pouring the proper amounts and inventory control are the two most crucial components to making bars and restaurants profitable. Unfortunately, factors like over pouring and give aways (stealing) is a never-ending issue for all restaurants and bars due to this main reason; bartenders make more money pouring stiffer drinks and giving away free drinks. It is impossible for management to monitor every drink poured every single day especially in high volume situations. There are currently no real-time solutions to these huge financial losses which affect the smallest mom and pop facilities as well as the big chain restaurants and bars. The best pour regulator out now (The Perfect Pour) lets bartenders pour the proper amount for 1.5 ounces but it slows down turnover and inhibits pouring doubles because doubles are not actually double the amount, yet just a stiffer drink. It also inhibits pouring multiple drinks simultaneously and does not provide inventory tracking. The Accumat attaches to the bottom of the bottle and is a scale that exactly tracks the amount of alcohol dispensed then deducts it from inventory to ensure perfect tracking. Its also has a wireless connection to the bars point of sale system so any giveaway and over pouring is logged in real time and can be remedied immediately to stop financial and inventory leakage. The faulty bartender is held accountable on each and every over pour.

There are companies in the industry that can be hired to come out and weigh the bottles but at over $300 per visit can be extremely expensive to the business. The most notable company called Bevinco which is used in every episode of the tv reality show “Bar Rescue” offers this service but due to the price because of the labor involved, restaurants/bars will contract them to check inventory every 1-2 weeks which helps but it only gives you a snapshot of all the bartenders over 1-2 weeks limiting the ability to pin point the problem employee. When a loss over the 1-2 weeks is detected, the next step would be to call Bevinco out every day for at least one week to identify the specific employee causing the losses which would cost over $2000 for Bevinco and thousands more in leakage while trying to pinpoint the problem bartender. The Accumat gives management real time loss statistics as well as removes the exact amount from inventory all at once. Any faulty pouring or giveaways are immediately logged in the point of sale system allowing management to correct the problem at the end of the shift before losing 1-2 weeks of sales and inventory loss. Many huge restaurant/bar chains like Top Golf use Bevinco and similar services. Attached to this briefing will be examples of reports from small business that do well but nowhere near produce the volume of these giant restaurants where the amount lost revenues can be more than 5 times of these small business. Small businesses in this industry lose $10k-$30k in revenues due to this issue so you can imagine chains with multiple locations and 5 times as many sales could use a product like the Accumat. The question becomes how much would a corporation pay for a product that saves them tens of thousands of dollars per month?

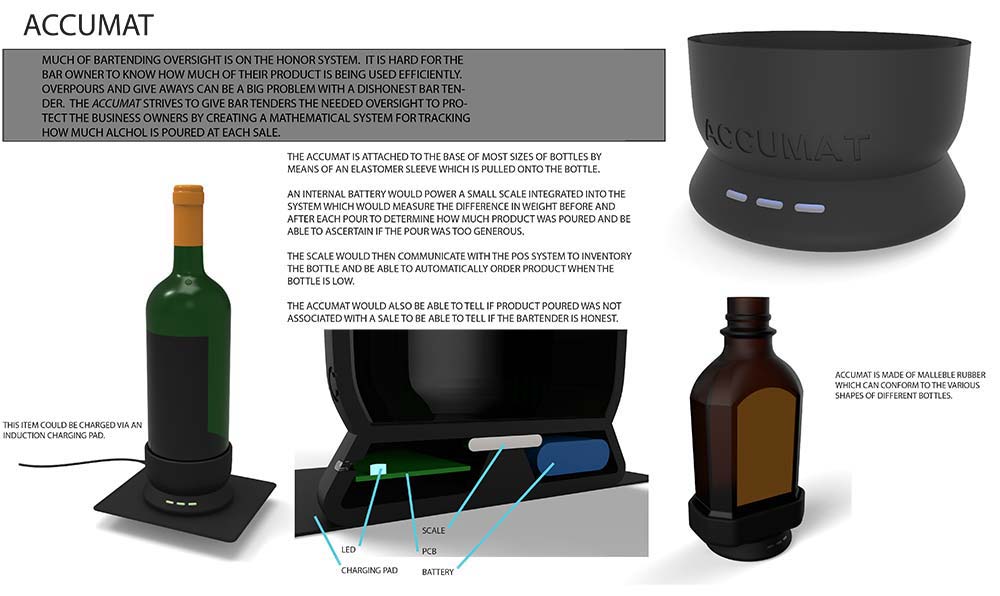

As seen in the renderings, the Accumat is a small elastomer sleeve that attaches to any type of bottle. Located at the base of the Accumat is a small internal scale that integrates with the point of sale system. Each and every time a cocktail is ordered the scale measures the weight of the bottle and deducts the exact amount poured and removing that amount from inventory for perfect reordering. The data sent to the point of sale system can automatically reorder to prevent running out of stock. This cannot be manipulated by adding another fluid back to the bottle either because each alcohol has a different weight which is calibrated into the system. The Accumat charges via wireless technology simply by placing the bottle on the charging mat which conveniently sits in the alcohol service well.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Eliminates inaccurate pouring of drinks

- Increases training of employees on how much to serve

- Increases profits by limiting losses

- Detects dishonest persons stealing inventory

- Direct reporting to POS system database for re-stocking and inventory

- Easy and quick to attach and remove

- Can be used on different shaped bottles

- Re-chargeable battery power

- LED lights determine battery status

- Wireless operation

- Charges on induction charging mat(s)

- Waterproof and can be washed

PRODUCT COMPONENT CLARIFICATION:

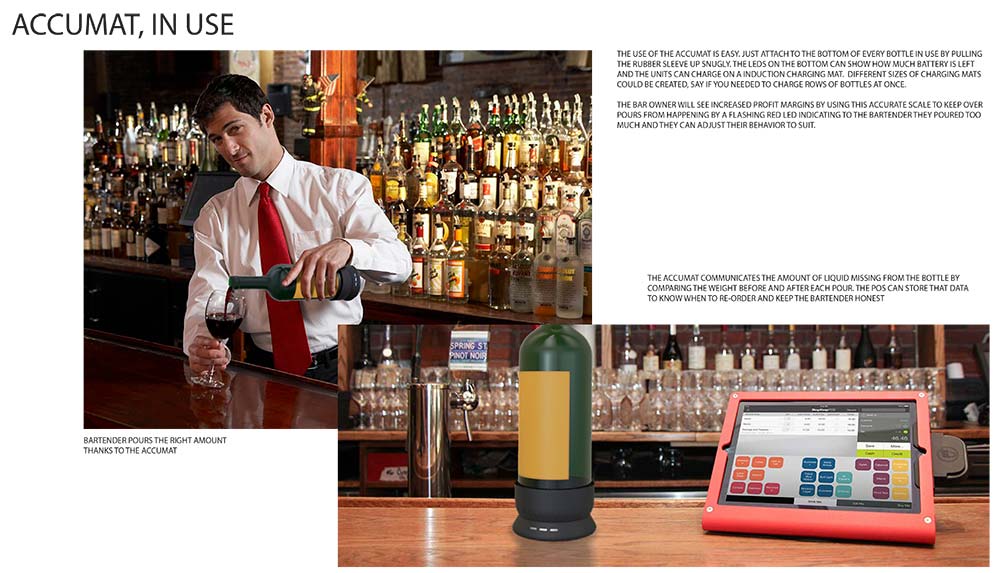

The “Accumat” is an innovative bartending product that has been designed to help the bartender make the proper pours and encourage honesty. The product consists of a system that measures the weight of the alcohol in the bottle after it is returned to the bar shelf and transmits it to a point of sale terminal, where it is compared with the value before the pour. Any discrepancy is logged, the bottle’s base red LED is turned on, and the data logged against that bartender’s file at the POS terminal, then transferred to secure storage. Multiple mis-pours and/or pours without logging the drink sold, will provide data to bar owner or manager so they can control the labor and costs more effectively.

Currently, over pours and free pours can cost the bar owner or manager several hundreds of dollars every evening. Having dishonest bartenders is a major contributor to this type of losses. They give away drinks or pour ‘heavy’ to their friends, or drink themselves. Another cause of losses is not mixing the drinks properly and incurring waste (lost revenue) as they have to be remixed. A side issue to the poor mixing, is a loss of repeat customers as they will not return if the drinks are mixed improperly.

The “Accumat” system resolves most of these issues by a system that allows the bartender to rapidly drill down into several menus on the point of sale terminal to find the bar’s recipe for the drink, lights the base of the bottles to be used, weighs the alcohol before and after the pour, and then logs the results against the bartender’s ID. The POS terminal has a card reader so the bartender can keep their card on the lanyard, swipe it to engage the POS terminal, find the drink and enter it. The recipe is then shown on the terminal and each of the bottles are identified using the yellow LED. After the drink is poured and the bottle is returned to the bar shelf, the remaining fluid is weighed and the value transmitted to the POS terminal. This number is compared to the previous reading and if it is within normal parameters, the bartender is not cited and the selling price is transmitted to the tab. If the pour is wrong or the wrong liquor is selected for the drink, the bartender log is cited, the current alcohol weight is placed in the look up table, the POS terminal suggests a re-mix or accepts the drink’s accuracy, and submits the selling price of the drink to the tab.

For example, let’s say the patron ordered a Long Island Tea. The recipe is:

- Over 6 large cubes of ice in a 12-ounce glass, pour

- 1 ounce vodka

- 1 ounce tequila

- 1 ounce rum

- 1 ounce gin

- 1 ounce triple sec

- 1.5 ounces of sweet and sour mix

- 1 splash of coca cola

- In this case, the base of each of the 4 bottles of bar alcohol would be blinking yellow. After prepping the glass, the bartender would follow the POS recipe, pour 1 ounce from each of the blinking yellow bottles, and then would return them to the shelf. If the pour was correct, the green LED would blink. After the 4 bottles were returned to the shelf and the bartender received blinking green lights, they would proceed to finish mixing the drink, then mark complete on the POS terminal. All the RF links are at the speed of light, so the response would not slow the bartender at all.

- If there was an under or over pour, or a missed element, the bartender’s file would be logged and the error corrected. The bottle with an error would blink red to teach the bartender and let them know that their file was updated with the error.

- After 15 seconds of blinking, the current level of fluids would have been noted in the look up table, and then all the LEDs lights would shut off, awaiting the next engagement.

The are some basic system considerations. These are, but not limited to, the following.

- It is assumed that just wine and alcohol bottles would be measured by the weighing system. Mixes, juices, and beers would not use the system.

- Exchanging empty bottles for the full ones is a simple two step setup. The base with the empty bottle is set upon the bar top. The POS has a “REPLACE” icon, which upon touching weighs the empty bottle so it can be tared out, the empty is removed, the new bottle placed in the base, the icon is touched again, the bottle weight is tared off the current weight, and the bottle replaced upon the bar shelf for use.

- Setting up a new bottle is equally easy. The bartender turns on a charged base, verifies that the POS station has located its ID, and drills down the menu to the fluid name inside, then touches the name icon to lock it in. The POS system uses the look up table to tare off the bottle weight, and then adds the new bottle’s weight to the look up table inventory.

The LEDs have 4 states, which can be used to alert the bartender and owner/manager as to the current state of the base and thereby the bottle contents. Some have been assigned for use in this document but any or all can be re-assigned.

| LED Color | Operation | Indicates This State |

|---|---|---|

| Green | Off | System off |

| Green | One 0.5 second blink every 5 seconds | Bottle logged, operational |

| Green | Blinks on and off at 0.5 second rate | Pour was correct |

| Green | On full | Data being logged acceptably |

| Yellow | Off | System off |

| Yellow | One 0.5 second blink every 5 seconds | Base being charged successfully |

| Yellow | Blinks on and off at 0.5 second rate | Base needs charging, below 25% |

| Yellow | On full | Fluid selection correct |

| Red | Off | System off |

| Red | One 0.5 second blink every 5 second | Base needs charging NOW |

| Red | Blinks on and off at 0.5 second rate | Pour was not correct |

| Red | On full | To be assigned |

| R&Y | Blinking on & off at 0.5 sec rate | Bottle needs to be replaced |

The system consists of three separate items. The POS terminal, the fluid weighing bases, and the charging mat. The bases are serialized and shipped from the factory in groups of 20 paired to the POS terminal. Up to 100 bases can be utilized per each POS terminal. The bases have a free air range of 100’ so will work within almost any bar. The bases and POS terminal work within the 402 to 470 MHz radio frequency (RF) band. They can transmit/process data at a rate so as to not impede the serving capability of up to 5 bartenders per POS station. Each of the POS terminals has a secure memory backup located offsite, typically in the cloud, to preserve the security of the bartender’s files. The “Accumat” devices are manufactured using the highest quality components and consist of, but are not limited to, the following.

The base: The base is pulled up on the bottle, retaining it upon the weight plate, which presses against the load cell. When the bottle is lifted, poured, and then replaced upon the bar shelf, the ending weight is taken and transmitted to the POS terminal. Each of these consists of, but is not limited to, the following components.

- The base housing and rubber overmold: This lower housing is injection molded from polypropylene plastic. This plastic is very durable, resists drop shocks, and is often used in this type of application. All of the electronics are installed in this shell and tested for viability. The protective plastic housing for the electronics is covered with molded silicone rubber overcoat, which protects the electronics, the bottle support plate, and is used to grip the bottle. The molded rubber can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The lower half of the base contains all the electronics and interfaces with the bottle support plunger to make sealed unit. These are as follows.

- The battery: This is a 5 VDC, 1810 MAHr Li-Ion battery. It is configured for this application and provided by a world class battery manufacturer. Connections are pre-configured using a common connector available in the industry. These connections are adhesively sealed to prevent water intrusion.

- The electronics: These are low power consumption components including the microprocessor. Obsolete cellular phone devices are ideal for this application and should be researched before other components are selected.

- Movement detection: The bottle movement is detected using an accelerometer and gyrometer, interrupting the weight measurement until the bottle is returned to the bar shelf and is not moving for a minimum of 1 second.

- The LED modules: These are red, yellow, green modules that are commercially available. The through-hole devices are mounted on their sides on the PCB with the LEDs oriented outward. The light emitted from the LEDs is slightly diffused by the frosted surface on the exterior of the end of the molded plastic light pipe.

- The RF section: This section consists of the transceiver operating at 402 to 470 MHz RF band, are serialized, and are capable of being programmed to be matched to the controlling module. The antenna is circular is arranged around the edge of the electronics module.

- The load cell: This load cell is a 5-pound capacity unit with NIST traceable calibration. It is capable of resolving a ±0.05 ounce load so 0.5 up to 2.0 ounces are easy to discriminate. The load cell is engaged by the bottle support plate and plunger, which rests upon the movable arm of the load cell. The plunger is sealed using low drag O-rings to keep any fluid out of the lower electronics chamber.

The POS Terminal: This station assigns, transmits, and listens to the output of the base modules. The serialized base modules are assigned to the controlling transceiver at the factory. The housing and display surround are molded from polypropylene plastic. This plastic is very durable, is highly resistant to household and bar chemicals, is easy to clean, resists drop shocks, and is often used in this type of application. The commercially available electronic components are purchased, assembled on a PCB, tested, and then inserted in the housing. The RF section uses the commercially available antenna to effectively couple the transceiver to the base(s) and the transceiver has a range of up to 100’ in free air. The commercially available touchscreen display is armored to prevent damage from inadvertently dropped glasses, yet is very sensitive to the touch, allowing efficient operation. The POS terminal should have the following capabilities at a minimum.

- Windows 10 professional, 64-bit operating system

- 7th Gen I-5 processor, 2.3GHz, dual core

- 4 GB of standard memory

- 128 GB of solid state memory

- 15.6” touch screen, 1366 by 768 resolution, full HD, WLED backlighting

- 802.11ac wireless LAN

- 4.0 Bluetooth

- Li-Ion 3 cell 4034 mAHr battery

- 120 VAC connection to an onboard 45W smart charger

The charging station(s): These wireless charging stations consist of a commercially available silicon rubber mat onto which up to 12 bases can be placed. The charger mat has rings printed on the upper surface upon which each base is to be placed, in 3 rows of 4 each. The charger uses the Qi standard and operates at medium power at 120W. The charging current transfer frequency is at ~140 kHz. The mat charges the Li-Ion batteries in the bases at a slow rate so there are no safety issues. The base modules will operate for up to 3 days on an 8-hour full charge. The mat is sealed so it can easily be wiped down using soap and water and dried to prevent any inadvertent accumulation of drink residue. One mat will typically handle up to 40 bases being charged randomly.

The printed circuit boards (PCB): The PCBs for all devices are fabricated to the final assembler’s requirements in a world class contract electronic assembler facility. The standard thickness, double sided FR4 circuit board material is populated with surface mounted components where possible. Any through-hole devices are inserted after the surface mounted assembly, soldering, and cleaning. Both circuit boards are designed to have all the components oriented so they can be mounted with the LED illuminators projecting out of the lenses mounted in the housings. After assembly, the PCBs are protected with a moisture adsorption preventive conformal coating.

The “Accumat” is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from improved accuracy in drink delivery and improved profitability, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

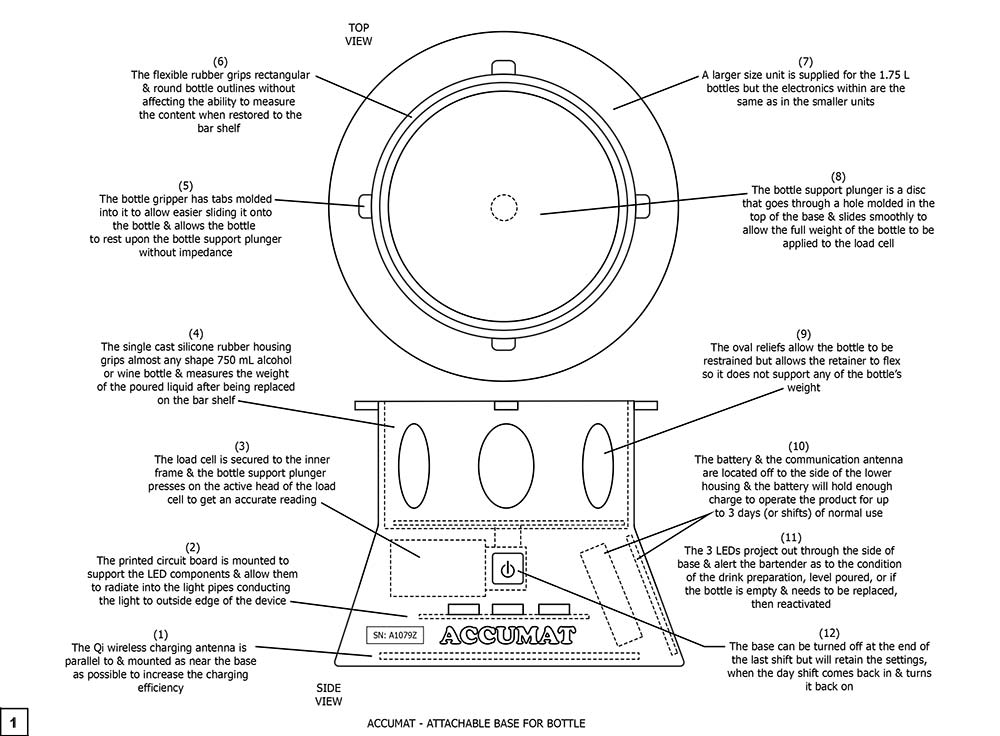

Drawing 1, Block 1: Accumat – Attachable Base For Bottle

(1) The Qi wireless charging antenna is parallel to and mounted as near the base as possible to increase the charging efficiency.

(2) The printed circuit board is mounted to support the LED components and allow them to radiate into the light pipes conduction the light to outside of the device.

(3) The load cell is secured to the inner frame and the botte support plunger presses on the active head of the load cell to get an accurate reading.

(4) The single cast silicone rubber housing grips almost any shape 750 mL alcohol or wine bottle and measures the weight of the poured after being replaced on the bar shelf.

(5) The bottle gripper has tabs molded in to allow easier sliding it onto the bottle and allows the bottle to rest upon the bottle support plunger without impedance.

(6) The flexible rubber grips rectangular and round outlines without affecting the ability to measure the contents when restored to the shelf.

(7) A larger size unit is supplied for the 1.75L bottles but the electronics within are the same as the smaller units. Even larger units can be supplied for well liquor containers.

(8) The bottle support plunger is a disc that goes through a hole molded in the top of the base and slides smoothly to allow the full weight of the bottle to be applied to the load cell.

(9) The oval reliefs allow the bottle to be restrained but allows the retainer to flex so it does not support any of the bottle’s weight.

(10) The battery and communication antenna are located off to the side of the lower housing and the battery will hold enough charge to operate the product for up to 3 days (or shifts) of normal use.

(11) The 3 LEDs project out through the side of the base and alert the bartender as to the condition of the drink preparation, level poured, or if the bottle is empty and needs to be replace, then activated.

(12) The base can be turned off at the end of the shift but will retain the settings when the day shift comes back in and turns it back on.

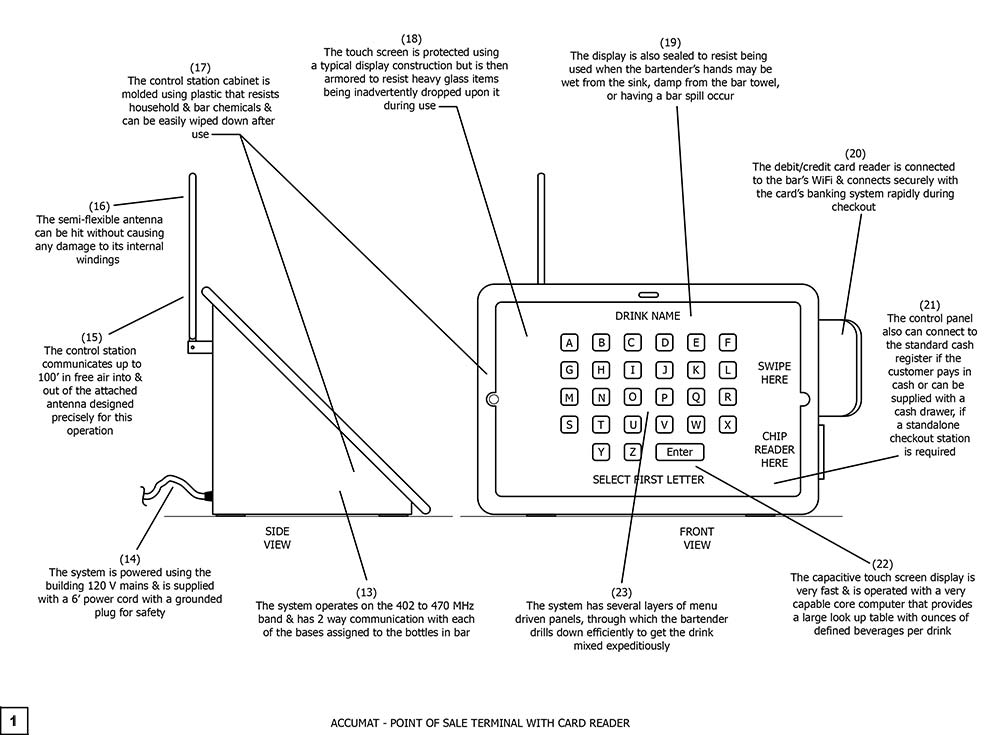

Drawing 2, Block 1: Accumat – Point Of Sale Terminal With Card Reader

(13) The system operates on the 402 and 470 MHz band and has a 2 way communication with each of the bases assigned to the bottles in the bar.

(14) The system is powered using the building 120 V mains and is supplied with a 6’ power cord with a grounded plug for safety.

(15) The control station communicates up to 100’ in free air into and out of the attached antenna designed precisely for this operation.

(16) The semi-flexible antenna can be hit without causing any damage to its internal windings.

(17) The control station cabinet is molded using plastic that resists household and bar chemicals and can be easily wiped down after use.

(18) The touch screen is protected using a typical display construction but is then armored to resist heavy glass items being inadvertently dropped upon it during use.

(19) The display is also sealed to resist being used when the bartender’s hands may be wet from the sink, damp from the bar towel, or having a bar spill occur.

(20) The debit/credit card reader is connected to the bar’s WiFi and connects securely with the card’s banking system rapidly during checkout. The reader also accepts the bartender’s ID card allowing them to log in rapidly, especially when the card is worn on a lanyard hanging from the neck.

(21) The control panel also can connect to the standard cash register if the customer pays in cash or can be supplied with a cash drawer, if a standalone checkout station is required.

(22) The capacitive touch screen is very fast and is operated with a very capable core computer that provides a large look up table with ounces of defined beverages per drink. (See the Long Island Tea example above).

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.