Case Packs

DESCRIPTION:

Vessels utilized to carry water and other beverages developed with the early civilizations but the bottling of water began, as far as some historical records go, in the United Kingdom in the 1600’s. The resurgence of spas and water therapy created a demand for bottled water among American colonists and Europeans in the 17th and 18th centuries. The first production of commercially available bottled water was sold and distributed by Jackson’s Spa in Boston in 1767. Bottled spa water was believed to have therapeutic properties and that bathing or drinking the water could improve the health of the individual involved. The popularity of bottled water lead to other entrepreneurs bottling various types of water to simulate the mineral water found at spas. The innovation of glass bottles in the nineteenth century was due mostly to production technologies improving the making of glass and lowering the cost. The nineteenth- century municipal water supplies suffered from pollution and the drinking of water from bottles was consider a safer alternative.

The introduction of water chlorination in the United States led to a decline in the consumption of bottled water, but it remained popular in Europe. In 1977 Perrier launched a successful advertising campaign in the United States. The Perrier advertising campaign brought about a resurgence of popularity in the United States for bottled water.

The DuPont Corporation developed the first water bottle able to tolerate the pressure of carbonated drinks in 1973. The material used for the new bottle is Polyethylene terephthalate or otherwise known as PET. Currently, the PET bottle has almost entirely replaced glass as the preferred material for single-serve bottle containers.

The single-serve plastic bottle is often used to mix flavored products within the bottle creating a flavored beverage according to the individual’s preference. The drink mix is usually powered processed-food product designed to mix with water to produce a beverage simulating a fruit juice or some other flavor usually associated with sodas. Some of the products include vitamins and other nutrients including supplements and protein packs that are associated with health-conscious individuals seeking to supplement their beverages. The flavor packs come in various styles and packaging methods designed to sell and attract consumers to purchase their particular brand of flavoring supplement. One of the difficulties with the flavor and supplement pack is getting the products into the bottle. Many manufacturers seem to concentrate on selling the product and ignore the fact that the consumer has to get the product into a narrow opening in the top of a water bottle. The process of getting a product into a water bottle is often the source of an accidental spill of the product either all over the surface of the bottle, the surface that the bottle is sitting on if any or all over the consumer.

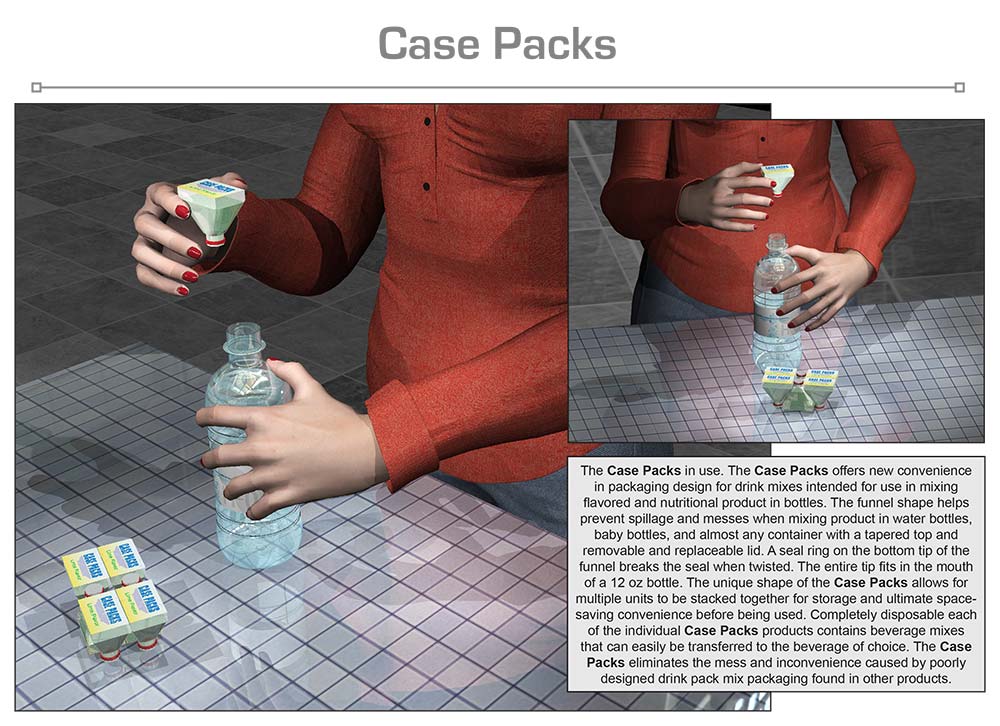

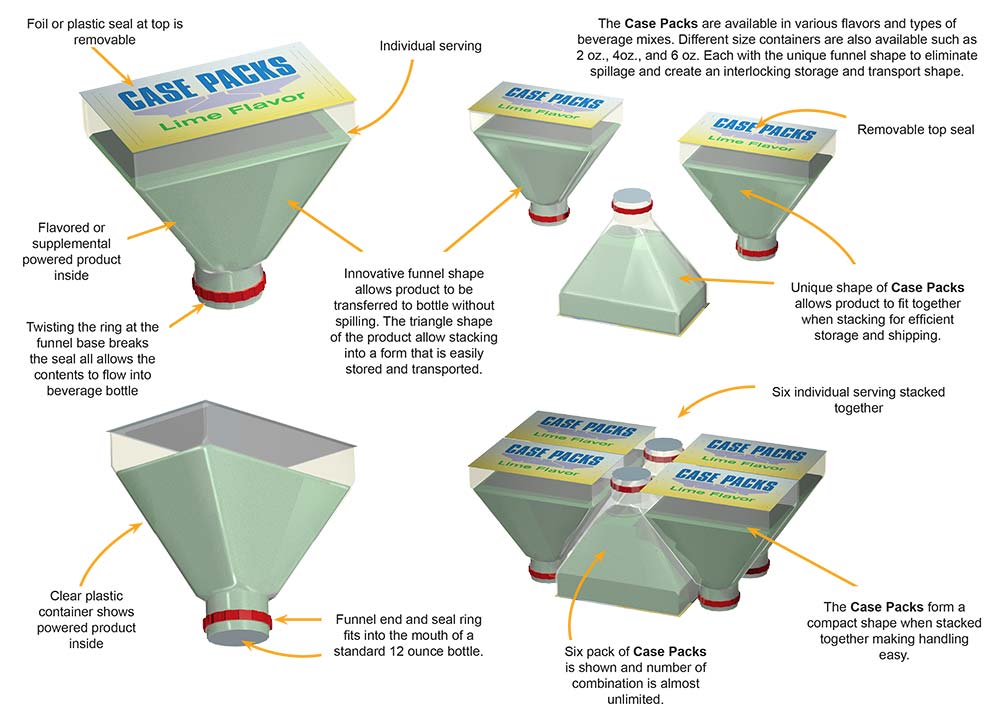

The Case Packs is a unique and innovational product designed to solve the issue of spillage when introducing a powered drink product into a water bottle or other types of similar containers. Consisting of tapered funnels shape the Case Packs fits neatly on the top of a water bottle opening. A ring located on the funnel tip breaks the seal when twisted and the entire funnel tip will fit into a 12-ounce bottle mouth eliminating any accidental spill of the contents. The tapered funnel shape allows gravity to pull the contents of the Case Packs quickly and evenly into the container. The bottom cylinder shape has a removable seal that once removed allows the flow of the contents directly into the bottle. Once the product is emptied into the bottle the Case Packs container can be disposed of or recycled. Each Case Packs container is designed to stack evenly with each other. The form fitting-shapes allow the product to fit neatly together to form stackable shapes that are easy to store and transport. The Case Pack can eliminate the spilling of powered products when mixing products with bottled beverages. The unique funnel interlocking shapes create an efficient packaging solution that will save time and money.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Prevents spillage when mixing with bottle beverages

- Ring located on funnel tip breaks seal when twisted

- The entire funnel tip including ring will fit into the mouth of a 12 oz. bottle

- Funnel shape is efficient

- Various flavors of beverage mix available

- Works with all kinds of beverage bottles, water soda, baby bottles, etc.

- Quickly and easily applied and removed

- Completely sealed and ready to apply

- Top and bottom have breakable and removable seals

- Cylinder shape on bottom of funnel shape inserts into bottle

- Unique shape of product allows easy stacking and storage

- Interlocking shapes create rectangular shapes when stacked together

- Quality and durable materials assure product shelf life

PRODUCT COMPONENT CLARIFICATION:

The “Case Packs” is an innovative personal hydration product that has been designed to add powdered flavoring to 12-ounce commercial water bottles. This innovative method utilizes a food grade container that screws onto the top of the water bottle, injects the powdered flavoring into the water bottle without drama or spillage, and can be recycled to reduce the impact on the environment. The shape of the container allows for extremely compact storage and the quantity of the powdered flavoring within is carefully sized for the optimum in flavor for a 12-ounce water container.

Currently, the flavoring of a water bottle can be very messy, especially if the wind is blowing very harshly or the user has shaky hands. The result means powdered flavoring is scattered all over everything, for example, the user’s clothes, the vehicle if they are sitting inside one, etc. Because these flavorings are very soluble and contain typical fruit or vegetable colors, staining can be a real problem. Additionally, many of the flavorings contain synthetic compounds or sugars. These can make a very sticky mess upon whichever surface they may land upon, requiring extensive cleaning processes.

The “Case Packs” resolves most of these problems by providing an inexpensive flavoring injection device that prevents any loss of flavoring or any spills of the powder. The food grade plastic container is inexpensive and does not add too much additional cost to the flavoring. The empty container is also recyclable so it can have a very small impact on the environment. The product is easy to use. The cap is removed from the bottle of water and retained. Then the bottom protective seal is removed from the flavor container and discarded. Then the product is screwed onto the water bottle, the ring rotated about 90° (opening the trap door), and the flavoring flows smoothly into the water bottle. There is no loss of flavoring compounds nor any airborne dispersal of same. The user taps the container, effectively emptying the container and then removes it from the bottle, disposing it in the recycling bin. Then the bottle cap is re-installed and the bottle shaken to completely distribute the flavoring throughout the bottle. The shape of the flavoring container allows very compact storage and a unique look as well as easy decanting of the flavoring into the water bottle.

The container and lower fill neck: The container is injection molded using food grade, translucent polypropylene plastic. The thin walled product is rectangular in shape with tapered walls that are gently curved in the corners to allow quick and easy emptying of the powdered flavoring. The lower fill neck unit is a 2-piece device that has a scored but not penetrated trap door. Into this, a spoked wheel with trap door operator is inserted. The trap door operator extends through the trap door on one side. The opening is slight interference fit on the operator, preventing any flavor powder from leaking out. The assembled trap door and bottle interface unit is press fit onto the reservoir, where it is thermally sealed to make a complete unit.

The labels: The labels (sanitary seals) can be supplied in almost any vibrant color, lettering, or logo, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The flavor and expiration date will also be included upon the label/seal. The labels are metalized Mylar which has been adhesively coated on the Mylar side that contacts the polypropylene wall edges. The metallization prevents any transition of oxygen or other airborne contaminants.

The flavorings: As an added health benefit, a line of freeze dried fruit and vegetables are ground and supplied in a fine powder form to make the optimum in healthy flavorings. These fruits and vegetables powders do not have any added sugar or other compounds and are so finely divided, they are 100% soluble upon contact with any water. They naturally do have moderate amounts of vitamin B6, vitamin C, manganese, and potassium, which contribute to human electrolyte balance. These flavors are, but not limited to, the following.

| Fruit Powder Flavors | ||

|---|---|---|

| Apple | Banana | Coconut |

| Black Currant | Cranberry | Cherry |

| Peach | Mango | Pineapple |

| Pomegranate | Pumpkin | Strawberry |

| Orange | Lemon | Lime |

| Spiced tea | Iced tea | Coffee |

| Vegetable Powder Flavors | ||

|---|---|---|

| Tomato | Celery | Spinach |

| Watercress | Carrot | Broccoli |

- As an option, some sugar, sugar substitute, salt, pepper, or cayenne pepper can be added to the flavor powders to make them more appealing to the general population for improved marketing of the product.

- As an additional option, the flavoring can be supplied with common additional compounds so the taste is close to being the same as flavorings currently on the market.

The Case Packs are designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from a very clean flavoring process and significantly improved storage, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

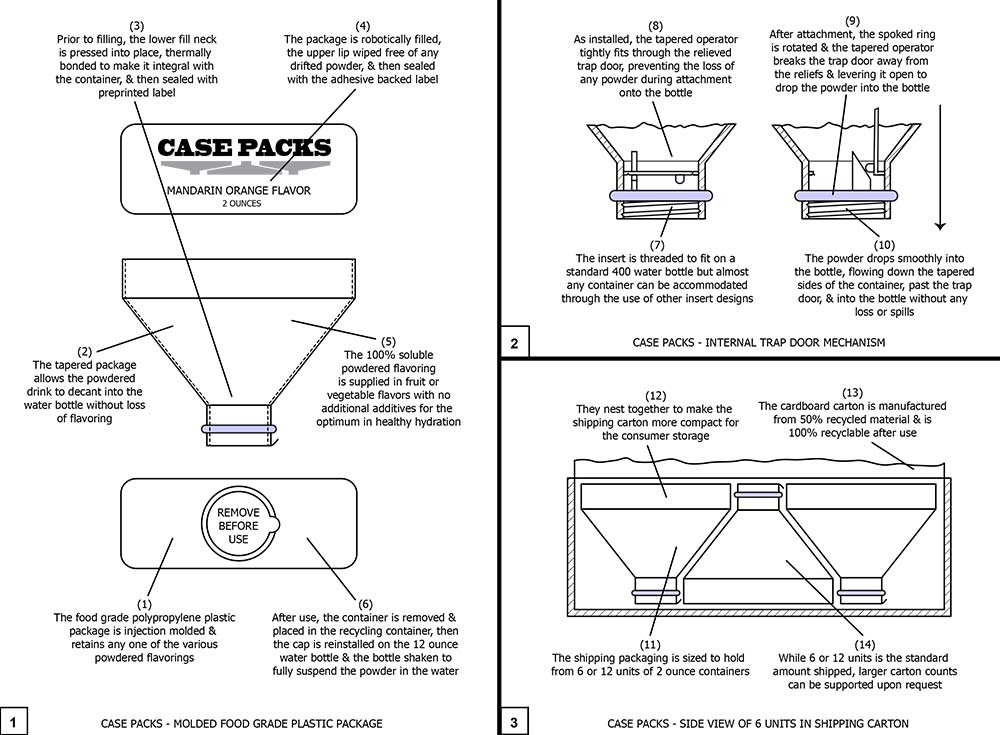

Drawing 1, Block 1: Case Packs – Molded Food Grade Plastic Package

(1) The food grade polypropylene plastic package is injection molded and retains any one of the various powdered flavorings.

(2) The tapered package allows the powdered drink to decant into the water bottle without loss of flavoring.

(3) Prior to filling. the lower fill neck is pressed into place, thermally bonded to make it integral with the container, and then sealed with the preprinted label.

(4) The package is robotically filled, the upper lip wiped free of any drifted powder, and then sealed with the adhesive backed seal.

(5) The 100% soluble powdered flavoring is supplied fruit or vegetable flavors with no additional additives for the optimum in healthy hydration.

(6) After use, the container is removed and placed in the recycling container, then the cap is reinstalled on the 12-ounce water bottle and the bottle shaken to fully suspend the powder in the water.

Drawing 1, Block 2: Case Packs – Internal Trap Door Mechanism

(7) The insert is threaded to fit on a standard 400 water bottle but almost any container can be accommodated through the use of other insert designs. In those cases, the lower fill neck unit will be re-designed to fit the selected water bottle neck size.

(8) As installed, the tapered operator tightly fits through the relieved trap door, preventing any loss of powder during the attachment onto the water bottle.

(9) After attachment, the spoked ring is rotated and the trap door operator breaks the trap door away from the reliefs and levers it open to drop the powder into the bottle.

(10) The powder drops smoothly into the bottle, flowing down the tapered sides of the container, past the trap door, and into the bottle without any loss or spills.

Drawing 1, Block 3: Case Packs – Side View Of 6 Units In Shipping Carton

(11) The shipping package is sized to hold from 6 to 12 units of 2-ounce containers.

a. While the 2-ounce container is detailed in this document, the supplier could make other sizes of containers available, for example, 3-ounce, 4-ounce, 6-ounce, etc.

(12) They nest together to make the shipping carton more compact for the consumer storage.

(13) The cardboard carton is manufactured from 50% recycled material and is 100% recyclable after use.

(14) While 6 or 12 units is the standard amount shipped, larger carton counts can be supported upon request.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.