Compact Clay Launcher

DESCRIPTION:

Skeet shooting or clay shooting was introduced in the 1920’s by an avid grouse hunter Charles Davis of Massachusetts. This type of practice shooting quickly developed into a competitive sport and has a broad appeal to all types of shooting enthusiasts whether active in competitive areas or just for practice shooting. The shooting of clay targets thrown into the air is an excellent way to improve a person’s aim and reflex time for bird hunting or competitive sport. The United States military used clay shooting as a means to train gunners for action in World War II. The shooting of thrown clay targets is an excellent means of teaching the principle of leading and timing of a flying target.

The shotgun is the preferred gun, and several different types of shotguns are typically used. The guns range from small bore to larger and different settings for muzzle chokes are also used depending on the event or personal preference. Action on the guns is usually the pump action shotgun as it is the most popular and is preferred over manual load or automatics although all types are employed.

The clay that is most common is a standard in the United States and measures 4 5/16 inches by 1 1/8 thick and are thrown by a machine to 60 plus yards. The international clay is slightly larger and is thicker in the center making it harder to break and are thrown faster and for a longer distance.

The machines for throwing clays are large and bulky and are employed for loading multiple clays at a time. The machines are set to the required distance and are typically powered by electricity. The electric machine obviously requires a power source, and that will limit their mobility. Manual release machines are available but are limited in the number of clays that can be loaded at a time and many can handle only two or three clays before being reset.

Shooters often get around the limitations of expensive and bulky throwing machines by throwing the clays themselves or with an associate assisting them. The method of hand throwing clays can often lead to injuries from overstressing the arm and shoulder. The limitations of the human body also will limit the distance the clay can be thrown.

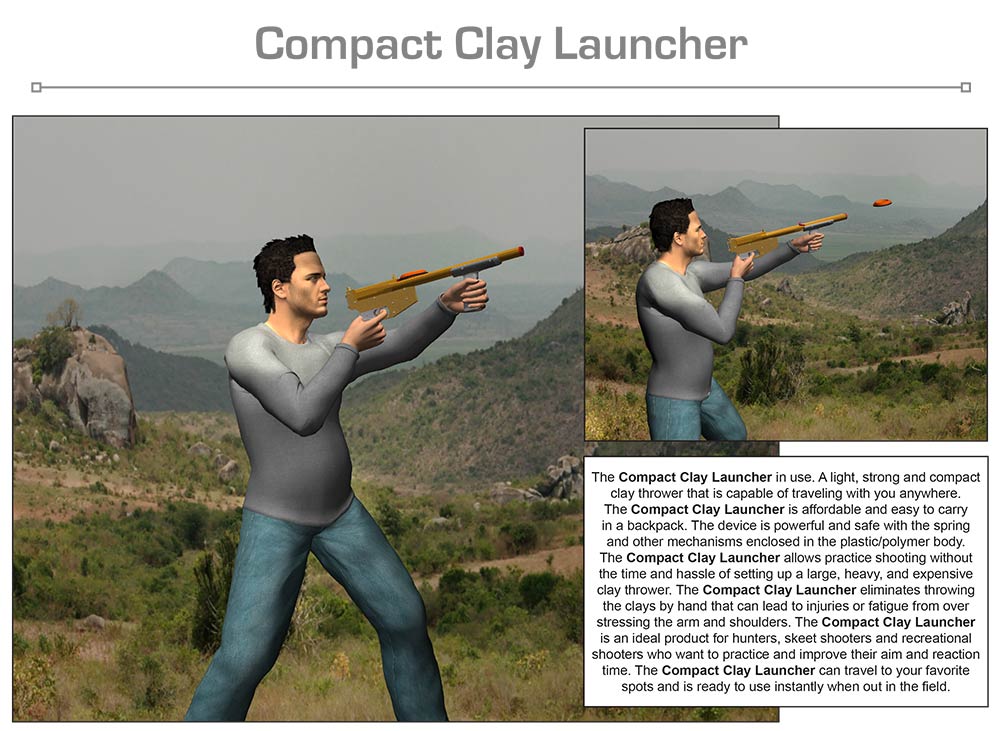

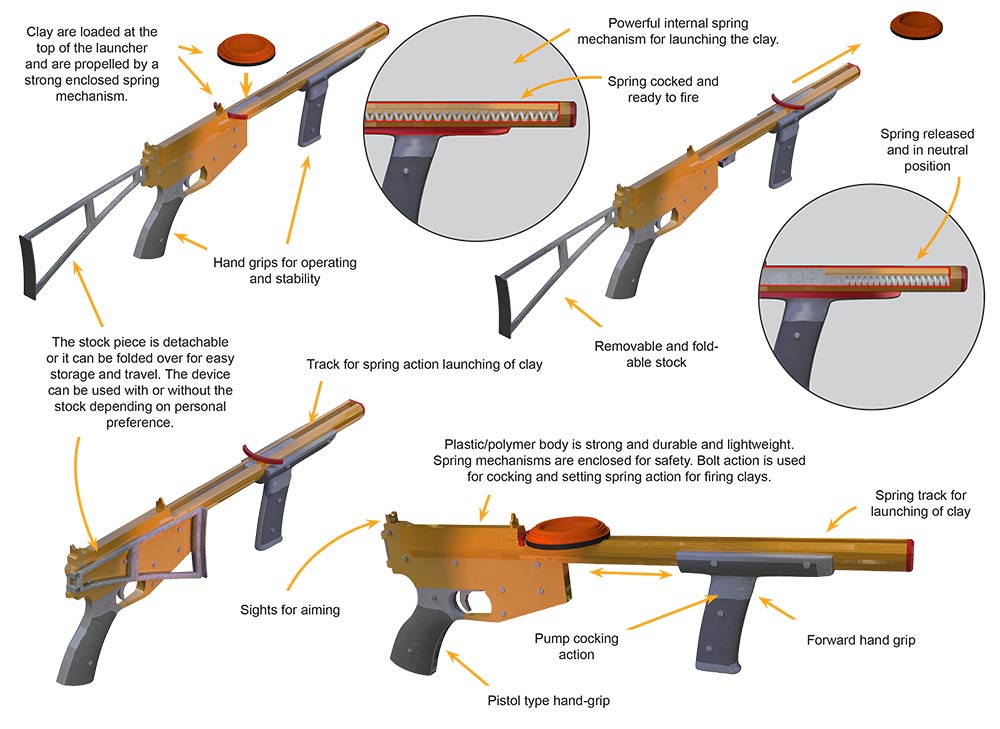

The Compact Clay Launcher is and innovative and unique solution to the issues associated with clay throwing for personal practice or sporting enjoyment. Constructed of durable plastic/polymer for the casing the Compact Clay Launcher contains a powerful spring that can safely throw a clay without the stress or fatigue of throwing it manually. The spring is safely enclosed in the casing of the Compact Clay Launcher to eliminate any danger from the recoil. The Compact Clay Launcher is shaped similar to a rifle for comfort and accuracy. The powerful spring is tensioned for throwing by a sliding pump action of the forward hand grip. Pistol type grips are located at the base and the forward section of the Compact Clay Launcher. The clay is loaded on the top of the device and is held in place by the clay holder piece. Once the trigger is pulled the clay is jettisoned by the release of the spring. The clay is guided by a rail located on the top of the Compact Clay Thrower. Sights located at the top rear of the product allow for aiming of the device. A foldable and removable stock is provided for individuals who prefer to use it. The Compact Clay Launcher is small, portable and can easily be carried in a backpack or with a strap. The lightweight, durable, and powerful Compact Clay Launcher can accompany the user on any outing where practice or competitive shooting can occur. The user is no longer dependent on hand throwing clays or resorting to heavy and expensive machines.

A hopper that holds 3 to 4 clay disks can be added to the Compact Clay Launcher to give added capacity without reloading after every shot. The hopper fits on top of the thrower where the loaded clay disks are positioned.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Lightweight and compact

- Plastic/polymer construction

- Powerful steel spring completely encased in device

- Safe and easily operated

- Potable and easily fits in backpacks

- Save arms and shoulders from injury or fatigue from throwing

- Pistol type grips on rifle configuration

- Foldable and removable stock

- Different color variations available

- Pump action to charge spring tension

- Throws clays considerable distance

- Additional hopper for 3 to 4 clay disks available

PRODUCT COMPONENT CLARIFICATION:

The “Compact Clay Launcher” is an innovative shooting product that has been designed to allow the user to easily launch competition clay pigeons without having to set up a complicated throwing machine or throw them manually. The shoulder supported, plastic bodied product is shaped like a gun and launches the clay pigeon through the use of a very strong spring. The product is cocked using a forward pump operator and is latched in the ‘cocked’ position using a proprietary latch. A ‘safety’ prevents the spring release by restricting the trigger movement. After use, the product’s stock can be folded and the compact unit can be placed in the nylon carry bag or backpack for transport or storage.

Currently, if the shotgun shooter wants to practice, they must take another person to manually launch the clay pigeons using a hand held throwing device or must set up a throwing machine. This machine can be manually loaded and manually tripped, requiring an additional person, or can be automatically loaded and remotely triggered by the shooter. In any case, organizing, setting up, and tearing down can be aggravating and very time consuming. Hand throwing is very fatiguing and not enjoyable.

The “Compact Clay Launcher” resolves most of these problems and provides a method of launching the clay pigeons (hereinafter ‘clay’) that is fun for the support companion, or alternate shooter. The gun shaped launcher accepts the standard competition clay pigeon that are about 4” in diameter and weigh about 4 ounces. The launcher is powered with a very strong spring and uses a carrier that cups the clay pigeon securely around half of its periphery. The spring is cocked using the forward mounted pump action grip, which is pulled back until the carrier locks. Then the safety is set to prevent inadvertent triggering and release of the spring pressure. The clay is place in the cup with the cupped base down and resting on the top of the barrel. The gun is pointed where the clay is to launched, the safety released, and the trigger depressed until the cable releases the clay carrier. Then the spring rapidly extends, the carrier slams into the rubber stop, and the clay is launched at 50 + mph. After the launching/shooting session is over, the clay dust is shaken out of the spring cavity, the barrel wiped off, the stock folded to lie against the gun body, and the launcher is placed in the carry bag.

- As an option: The cocking operation can be aided, or performed completely, through the use of a rechargeable DC powered drill motor and a ball screw assembly. The linear motion device will smoothly pull the slide back when the cocking switch is engaged, and will drive the shuttle system back until it latches. After the latching pawl is engaged, the linear motion device will return to the forward position within seconds. When the linear motion carrier is at rest, the safety can be released and the clay launched. The 18V battery will be supplied to latch onto the launcher and this option will be supplied with an 18 V charger that can operate on 120 VAC mains to charge the battery. Additional batteries can be purchased for a longer operating life. This battery powered cocking option will work with the 6 clay magazine.

- As an additional option: The product can be supplied with an add-on multiple clay magazine that can hold up to 6 clays for launching. The magazine will latch on to the launcher just above the C shaped shuttle when it is positioned at the cocked and locked position. When the shuttle is pulled into the cocked position, the magazine will allow 1 clay to be dropped into the shuttle for launch. Holding the balance in the magazine. The clay, after dropping into the shuttle, will clear the lower surface of the magazine for launch. This will allow the product to launch up to 6 clays nearly as fast as the cocking mechanism can be operated.

The “Compact Clay Launcher” is fabricated from many parts. These are, but not limited to, the following.

The launcher body: The launcher body sections are injection molded from fiberglass reinforced polyamide nylon thermoplastic. This plastic is very durable, is highly resistant to abrasion and drop shocks, has very high strength, and is typically used in this type of application. The individual components can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The product can even be supplied in various colors of camouflage. The sections are split down the center of the launcher and held together using multiple stainless steel fasteners. The butt stock is also molded using the thermoplastic and is secured to the launcher body using a stainless steel removable pin, which allows the butt stock to be removed, if desired. The thrower can also be carried in standard backpack, once the stock is folded, if the carry bag is not used. All of the components below are contained within the thermoplastic body and provide a smooth, economical operation over a long product life.

- The launch spring: This helical wound, compression spring uses 0.125” diameter type 302 stainless steel wire. The spring in the relaxed state is 20” long and is 1.5” in diameter. Its length when fully compressed is approximately 10” long exerts about 100 pounds of force on the shuttle when released. The stainless steel spring will not rust or corrode and is shotpeened and passivated for a long product life. The internal barrel sections are smooth and contain any sideways force exerted by the spring.

- As an option: The spring value can be reduced to slow the clay’s velocity slightly while dramatically reducing the pump action required to cock the launcher. Some empirical engineering can be employed by the manufacturer to find the smallest spring value for the maximum launch speed.

- The launch shuttle and clay carrier: This component is machined to shape in a CNC machining center from type 316 stainless billet. The cup is shaped with a rib on the back to reduce whipping of the cup ends at the rubber stop. The cup is an integral part of the shuttle, which fits into the windings in the last few turns of the spring. This allows the spring to absorb some of the rapid stop energy. The shuttle also extends below the spring to catch on the spring loaded trigger latch. After fabrication, shotpeening, and passivation, the cup is covered with a thin coating of urethane rubber to grip the clay better during launch.

- As an option: One of the cup arms may be extended with a small gripper to impart some spin to the clay, stabilizing it better than launching with no spin at all. Some empirical engineering can be employed by the manufacturer to find the optimum length extension versus flight perturbation parameters.

- The trigger latch: This is fabricated from type 302 stainless steel and is spring loaded so it depresses when the shuttle passes over it during cocking and extends to secure the shuttle in the cocked position. The trigger latch is cable or rod activated when the trigger is depressed and releases the shuttle, which in turn, accelerates the shuttle/cup down the barrel, launching the clay.

- The trigger assembly: This is commercially available aluminum trigger and safety assembly. The trigger slides backward into the trigger guard in the housing, pulling the trigger latch cable/rod. The safety prevents the trigger from being pulled backward, which prevents release of the trigger latch and keeping the shuttle in the cocked position.

The Compact Clay Launcher is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from an easy to set up and use device and an enjoyable launching effort, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

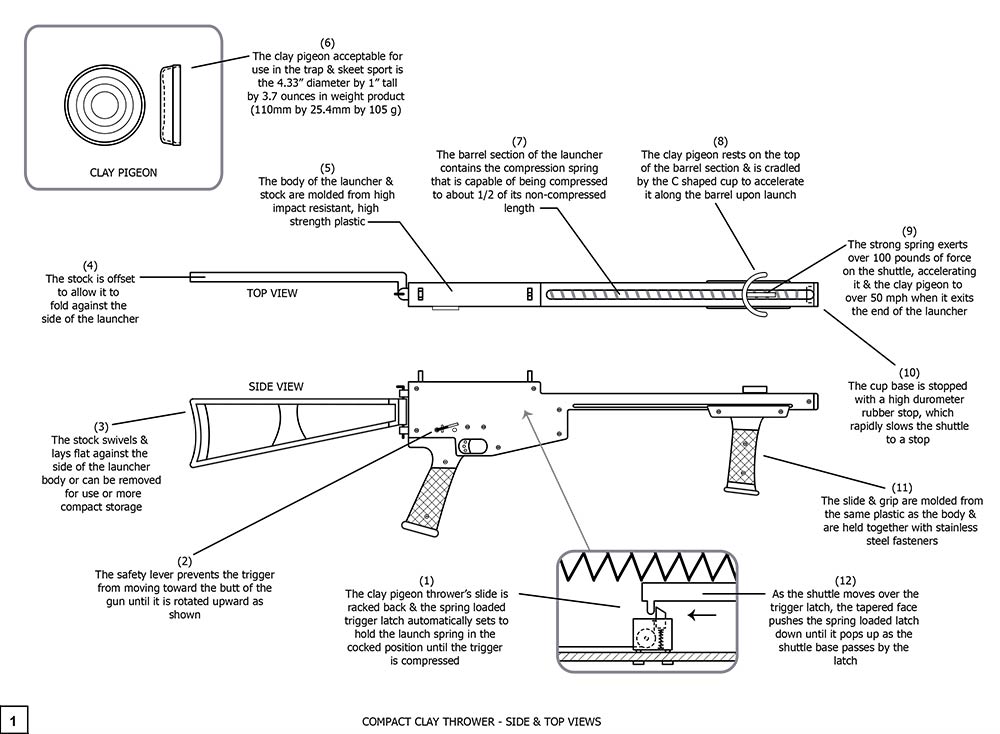

Drawing 1, Block 1: Compact Clay Launcher – Side And Top Views

(1) The clay pigeon thrower’s slide is racked back and the spring loaded trigger latch automatically sets to hold the launch spring in the in the cocked position until the trigger is compressed.

(2) The safety lever prevents the trigger from moving toward the butt of the gun until it is rotated upward as shown. When flipped up, the red dot is exposed so the user knows the clay thrower is ready to launch.

(3) The stock swivels and lays flat against the side of the launcher body or can be removed for use or more compact storage. The butt stock can be removed and the device held in the hands to launch the clays.

(4) The stock is offset to allow it to fold against the side of the launcher.

(5) The body of the launcher and stock are molded from high impact resistant, high strength plastic.

(6) The clay pigeon acceptable for use in the trap and skeet sport is the 4.33” diameter by 1” tall by 3.7 ounces in weight product (110mm by 25.4mm by 105g).

(7) The barrel section of the launcher contains the compression spring that is capable of being compressed to about 1/2 of its non-compressed length.

(8) The clay pigeon rests on top of the barrel section and is cradled by the C shaped cup to accelerate it along the barrel upon launch.

(9) The strong spring exerts over 100 pounds of force on the shuttle, accelerating it and clay pigeon to over 50 mph when it exits the end of the launcher.

(10) The cup base is stopped with a high durometer rubber stop, which rapidly slows the shuttle to a stop.

(11) The slide and grip are molded from the same plastic as the body and are held together with stainless steel fasteners. Also the mating surfaces of the sections snap together to aid in keeping the launcher together during use.

(12) As the shuttle moves over the trigger latch, the tapered face pushes the spring loaded latch down until it pops up as the shuttle base passes by the latch. The latch is pulled down when the trigger is pulled, releasing the shuttle and cup and allowing the spring to accelerate them along the barrel.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.