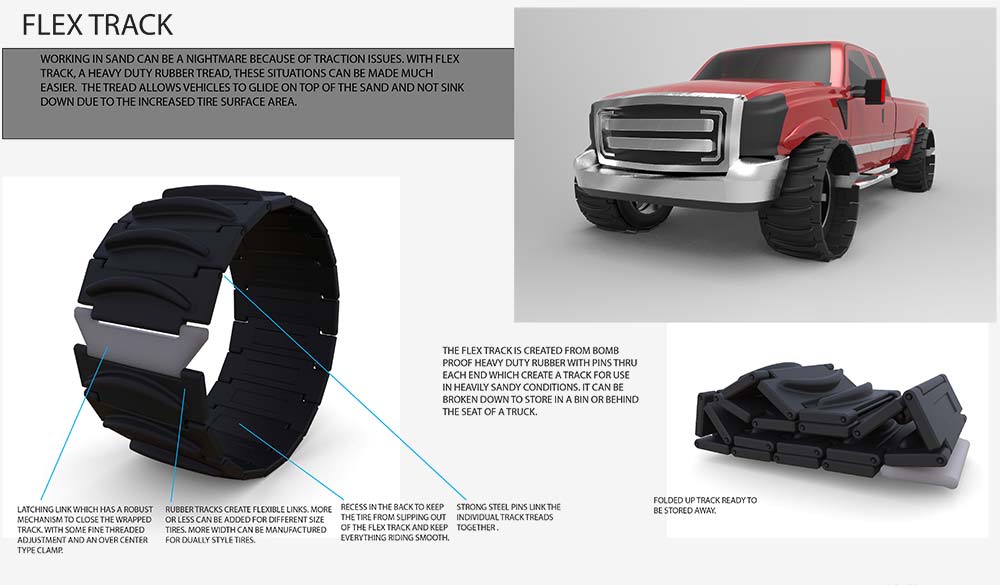

Flex Track

DESCRIPTION:

In 1770 Richard Edgeworth conceived a continuous track system. The track was crude and without a propulsion system available other than horse-drawn power so the system had limited uses. Other designs for a continuous track system continued to evolve through the 1800s until a little-known inventor Henry Stith developed a patented continuous track system. Stith received several patents on his invention, and the last was a bicycle-based system for off-road riding. His surviving family still maintains the prototype. Frank Beamond a British inventor designed, built and patented caterpillar tracks and patented them in a number of countries in the early 1900s.

A steam-powered log hauler was designed and built at the Waterville Iron Works in Maine in 1901 by Alvin Lombard, and it was named the Lombard Steam Log Hauler. Lombard was also granted a patent for his creation. In Great Britain, the continuous track vehicle was developed by a British agricultural company, Hornsby in Grantham in 1905. The military in Britain began to test Hornsby tractors for use as artillery tractors for the British army but was not adopted at that time. The caterpillar name was coined during a military test. The military did apply the continuous track to a prototype vehicle and became convinced that it was possible to develop a fighting vehicle.

The continuously tracked vehicles continued development, and the realization that tracked vehicles are far superior to wheeled vehicles in rough and wet terrains as well as loose soils and sand.

Up to this point, vehicle tracks were constructed of linked steel plates. Some of the manufactures of agricultural products began to utilize rubber tracks instead of the steel. The rubber was lighter, make less noise, create less ground pressure and do not damage paved roads.

The concept of a tracked vehicle has many advantages in terrain that is not suitable for wheeled vehicles. The design of the track places a broader footprint on the ground and distributes the weight of the vehicle more evenly. This concept is especially useful in heavy sand or mud where typically wheeled vehicles will bog down and cannot gain traction. The issue is the ability to travel on roads at speed and the ability to traverse deep sand and mud when necessary with the same vehicle.

The Flex Track presents a unique and innovative solution to the issue of driving a wheeled vehicle over sand and mud and keeping the vehicle from becoming bogged down yet keeping the vehicle available for normal terrain and road travel.

The Flex Track is created from highly durable rubber with pins through each end creating a track in conditions where the wheeled vehicle can be adapted on the spot to traverse an area of soft sand or mud. The Flex Track’s ability to be broken down into a small area for storage makes it ideal for carrying along on any trip that might involve traction issues. The Flex Track creates a flexible covering for the wheel that is composed of a series of rubber links connected by a latching link. The latching link has a robust mechanism to close the wrapped track with fine threaded adjustments and an over-center type clamp. The inside of the circular Flex Track is recessed on the inside to keep the vehicles tire from slipping out and keep the Flex Track functioning smoothly. Strong steel pins connect the rubber track and give the product the flexibility for producing superior traction in sand and mud that would otherwise bog down the vehicle.

The Flex Trak provides a large footprint that will enable a vehicle to cross terrain that will stop other vehicles that are not equipped with Flex Track. The ability to break down the product and store it in the vehicle or for 4-wheelers or other all-terrain vehicles gives the driver the advantage of knowing the vehicle can be converted at any time.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Product breaks down and can be stored in vehicle

- Works for 4-wheelers and other types of all-terrain vehicles

- Creates a large footprint especially good for traversing soft sand

- Latching link has robust mechanism and is adjustable

- More width available for Dual wheels

- Extremely heavy duty rubber construction

- Recess inside of product keeps vehicle wheel inside and centered

- Strong steel pins hold rubber treads together

- Works for almost any size tire

PRODUCT COMPONENT CLARIFICATION:

The “Flex Track” is an innovative vehicle product that has been designed to dramatically and quickly increase the ‘footprint’ of the tires on the vehicle for use in sand, snow, or soft soil. The quickly and easily installed track-like product is made from very durable, wire reinforced, vulcanized rubber sections, which are draped over the tire and secured with very strong over-center latches. The side location lugs keep the appliance on the tire and the cup shaped lugs bite into the soil or sand to enhance the traction. The significantly larger footprint at each tire allows movement of the vehicle while reducing the probability of getting stuck. After use, the tracks can be pressure washed, rinsed, air dried, and then stored until the next use.

Currently, if the operator of the vehicle wants to go into the loose sand, soft soil, or snow, they can take their chances with the off-road tire design, can add chains, or can remove the wheels/tires and add very expensive track assemblies. The tire width, lug design, and addition of chains can help improve the traction but does not solve the footprint size, allowing the vehicle to get stuck. Adding the track assemblies is not something that can be done spontaneously at the site and driving the vehicle on the street with the tracks installed is time consuming due to the reduced top speed. Track wear on the street is detrimental and replacement tracks are costly.

The “Flex Track” invention resolves most of these problems by providing a very durable product that can easily be stored in a bed box or the back of the SUV and then permitting easy installation when an impending loss of traction may occur or recreational use is planned. In that case, the tracks are removed from storage in or on the vehicle, they are placed ahead or behind the tires, and the vehicle is moved so the tracks can be draped and secured over each tire. These tracks increase the footprint of the tire significantly and are easy to install. After use, the over-center clamps can be loosened, the tracks dropped down off the tires, and the vehicle driven off the tracks. Then the tracks can be stored in the vehicle box or back of the SUV until they can be washed for the next use.

The track sections: these track sections are fabricated using modified rubber tire assembly techniques. The product sections are fabricated using brass plated steel wires. These wires are stored in a temperature and humidity controlled environment until they are run through roller where they are coated with a thin layer of skim rubber, after which they are woven into the stabilizing insert. Then the insert is placed in the extruder, where the section shape is created. After that, the ‘green’ section is transferred to the vulcanizer, where it is cured using heat and pressure. After vulcanizing, the section proceeds to the final finishing station for any trimming and inspection.

The mating end sections: These are stamped from 0.75” thick 6061 alloy aluminum sheet stock. These sections consist of the male and female mating sections. They are cut from the sheet stock using a numerically controlled water jet machining center, followed by a CNC milling center. After fabrication and cleaning, they are hard anodized to provide the optimum in surface hardness to resist scratching during use. The end sections have the over-center clamps and the anchors installed on the interior surface of the track using steel rivets.

The over-center clamps and anchors: These commercially available components are secured to the aluminum end sections using nickel plated steel rivets. These rivet heads are countersunk so they lie below the aluminum surface after installation. This reduces the wear on the rivet heads, providing a long product life during use. Each of the over-center clamps has a holding strength of 375 pounds or 750 pounds per track when locked into place. They provide enough force to prevent track slippage during use on most vehicles. The over-center clamps can be adjusted ± 1.0” in length allowing the user to fine tune the track’s grip on the tire.

The pivot pins: These pivot pins are turned from 0.50” diameter steel rod using a CNC lathe. After turning the pivot pin and the swaged end piece, all the pieces are cleaned, etched, and then dip coated in molten polypropylene plastic. After cooling and trimming, the pivot pins are fed into the axle retainer channels in the rubber track sections and then are secured using very high-pressure compression to permanently swage the pin and retainer together. Each assembly is adjusted using the number of sections to fit the desired tire circumference

Each tire size has a slightly different tire circumference and the number of sections is adjusted and assembled to fit this tire. There are many manufacturers and many tire sizes. The most common, but not limited to, manufacturers are as follows.

| Manufacturers | ||

|---|---|---|

| Apollo | B.F. Goodrich | Continental |

| Cooper | Falken | Firestone |

| Goodyear | Hankook | Kumho |

| Michelin | Nexen | Nitto |

| Sumitomo | Toyo | Yokohama |

| Off Road | ||

|---|---|---|

| Cepak | General | Maxxis |

| Mickey Thompson | ProComp | Super Swamper |

While the number of tire manufacturers and sizes seems to be overwhelming, with adroit assembly, manufacturing, and adjustability from the over-center clamps, the stocking units can be reduced to an easily managed level. For example, the Mickey Thompson off road line can be broken down into, but not limited to, the following circumferences.

| Tire Description | Circumference |

|---|---|

| 33×12.50 R 15 LT Deegan 38 | 102.42” |

| 33×12.50 R 15 Baja MTZP3 | 102.73” |

| LT 305/65 R 17 Deegan 38 | 102.42” |

| LT 305/65 R 17 Baja ATZP3 | 102.42” |

| 285/70 R 17 Baja MTZP3 | 103.67” |

| LT 305/55 R 20 Deegan 38 | 104.61” |

| LT 305/55 R 20 Baja ATZP3 | 104.93” |

| 305/55 R 20 Baja MTZP3 | 105.24” |

| 35×12.50 R 15 Baja MTZP3 | 108.70” |

| LT 315/75 R 16 Baja Claw | 108.39” |

| 315/70 R 17 Baja MTZP3 | 108.70” |

| LT 305/70 R 18 Baja ATZP3 | 110.27” |

| 35×12.50 R 20 Baja MTZP3 | 109.01” |

The Flex Track is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from significantly improved traction combined with less soil compaction, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

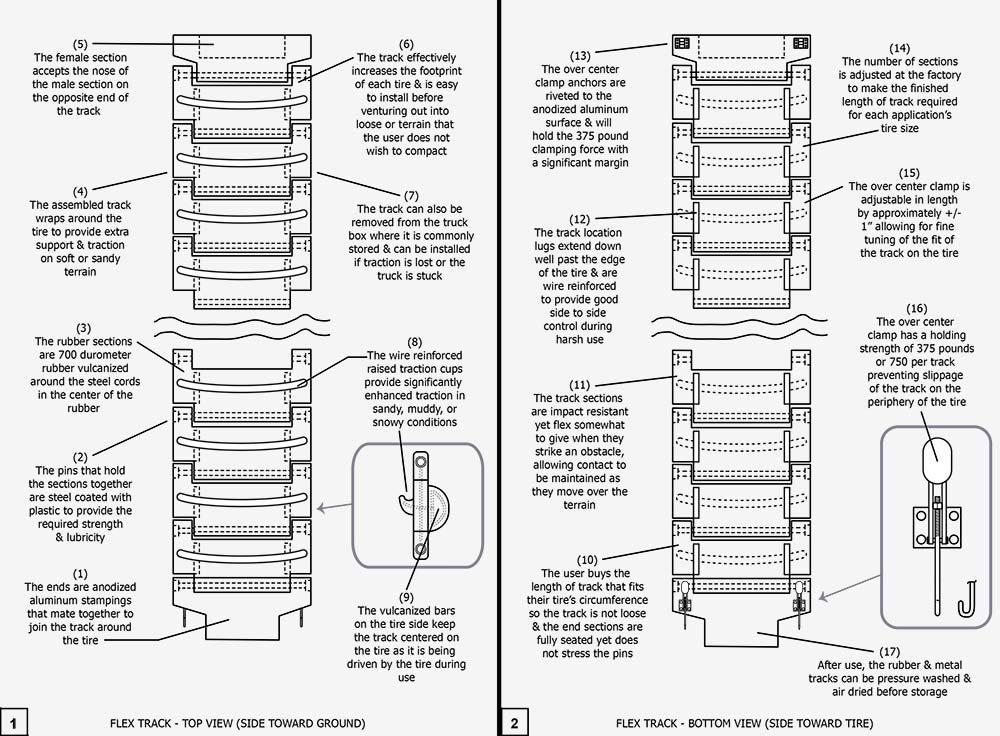

Drawing 1, Block 1: Flex Track – Top View (Side Toward The Ground)

(1) The ends are anodized aluminum stampings that mate together to join the track around the tire.

(2) The pins that hold the sections together are steel coated with plastic to provide the required strength and lubricity.

(3) The rubber sections are 700 durometer rubber vulcanized around the steel cords in the center of the rubber.

(4) The assembled track wraps around the tire to provide extra support and traction on soft or sandy terrain.

(5) The female section accepts the nose of the male section on the opposite end of the track.

(6) The track effectively increases the footprint of each tire and is easy to install before venturing out onto loose or terrain that the user does not wish to compact.

(7) The track can also be removed from the truck box where it is commonly stored and can be installed if traction is lost or the truck is stuck.

(8) The wire reinforced raised traction cups provide significantly enhanced traction in sandy, muddy, or snowy conditions.

(9) The vulcanized bars on the side keep the track centered on the tire as it is being driven by the tire during use.

a. As an option, the track location bars can be offset to make the track located farther to the outside of the tire so the turning radius is not affected as severely. If this technique is used, then there will be left and right side tracks supplied in sets of 2.

Drawing 1, Block 2: Flex Track – Bottom View (Side Toward The Tire)

(10) The user buys the length of track that fits their tire’s circumference so the track is not loose and the end sections are fully seated yet does not stress the pins.

(11) The track sections are impact resistant yet flex somewhat to give when they strike an obstacle, allowing contact to be maintained as they move over the terrain.

(12) The track location lugs extend down well past the edge of the tire and are wire reinforced to provide good side to side control during harsh use.

(13) The over center clamp anchors are riveted to the anodized aluminum surface and will hold the 375 pound clamping force with a significant margin.

(14) The number of sections is adjusted at the factory to make the finished length of track required for each application’s tire size.

(15) The over center clamp is adjustable in length by approximately ± 1” allowing for fine tuning of the fit of the track on the tire.

(16) The over center clamp has a holding strength of 375 pounds or 750 per track preventing slippage of the track on the periphery of the tire.

(17) After use, the rubber and metal tracks can be pressure washed and air dried before storage.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.