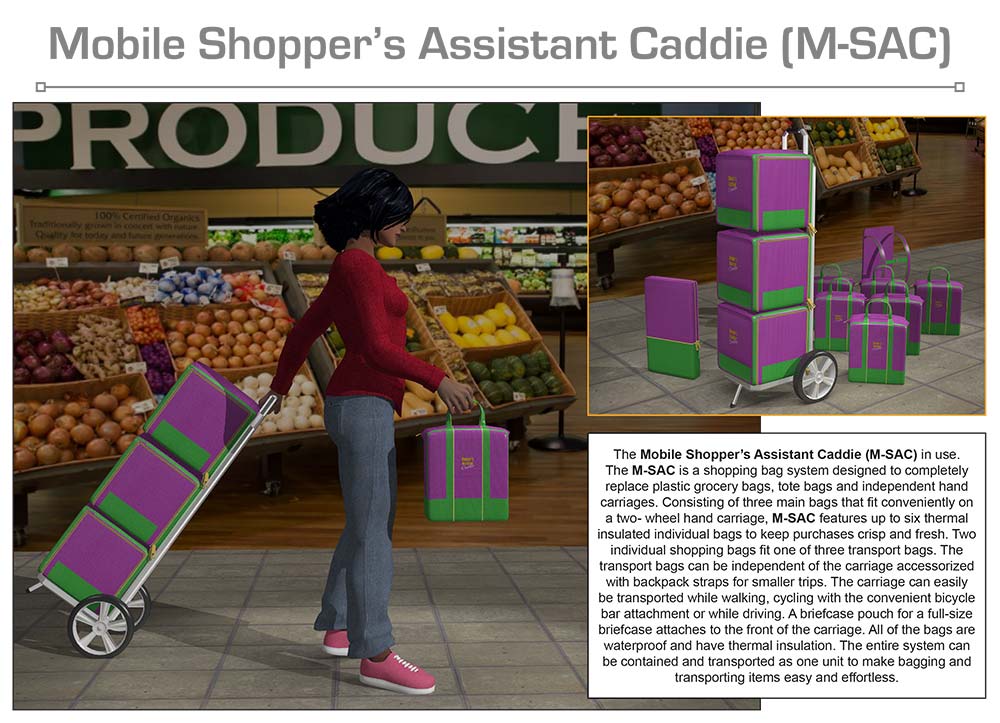

Mobile Shopper’s Assistant Caddie (M-SAC)

DESCRIPTION:

Grocery Shopping is a necessary event in most cultures around the globe. Depending on the country and its culture, this is the most common way to obtain food goods and other items for everyday living. In many cultures, a daily shopping trip is essential for meals and maintenance of the household. Homes without long-term storage or individuals who frequently shop for fresh produce, a daily visit is essential. Yet others shop to stock up for the week or longer. Whether the individual needs are daily or long-term, one of the most ubiquitous objects necessary is the shopping bag to hold purchased items.

In the United States and Canada, single-use plastic shopping bags were provided free by stores for customers’ convenience. However, recently the plastic shopping bag has come under scrutiny for its negative environmental impact. The use of these bags has created an increase in litter resulting in an excess in landfill congestion. The biggest problem with these single use plastic bags is that they are not completely biodegradable leaving an indefinite footprint on the environment. To help lessen this problem, many cities have enacted a band or a .5 to .7 cent surcharge on each bag.

Today’s consumer market has responded to these issues with the reusable shopping bag. Customers can purchase these bags from local grocery stores. Although the reusable shopping bag is a viable option, it too is limited in its use. For one, they are less efficient than the plastic bags for holding meat and poultry. Secondly, some bags are made from Hemp and since Hemp is avoided in the U.S., these bags are imported from China. Still others are made from polypropylene and polyethylene, a type of plastic made from recycled material, but is non-biodegradable. Lastly, there is no viable means of transporting purchased goods. Whether consumers are walking, traveling by mass transit, cycling or driving, transporting multiple bags from the store to their home would no longer be an awkward and challenging task.

The Mobile Shoppers Assistant Caddie (M-SAC) is an innovative solution to the issues of shopping bags and transport of purchased goods. Its unique all-in-one system is designed to hold, secure and transport groceries. The product consists of a lightweight rigid two-wheel hand carriage that will support up to 3 transport bags. Each of the transport bags contains two individual thermal-insulated shopping bags that are easily removed and replaced during the shopping trip. The thermal-insulated will keep refrigerated items cool for the trip home. The products hand carriage can stand upright on its own leaving the user hands-free to operate doors or other objects. The M-SAC features a bicycle bar that attaches to the seat post of a bicycle, a useful briefcase pouch for professionals that carry a briefcase, and backpack straps that attaches to one section of the transport bags. All bags and caddie are water resistant. The M-SAC offers a shopping bag and portable system that will eliminate all of the awkward and ungainliness of multiple shopping bags as well as being environmentally friendly.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Light-weight upright hand carriage

- Easily wheels around

- Stands independently

- Holds 6 individual shopping bags during transport

- Bicycle bar for hand-free riding

- Backpack straps for one transport bag

- Briefcase pouch that attaches to front

- Umbrella loops

- Waterproof bags and carriage

- Available in different color schemes

- Rugged construction

PRODUCT COMPONENT CLARIFICATION:

The “Shopper’s Assistant Caddie” is an innovative shopping product that has been designed to provide mechanical help is transferring goods from the store to the home in a typical city center, where cars are not very useful. The caddie product consists of leak resistant, insulated shopping bags, two of which fit in a durable transport bag. The individual transport bag can be carried using the available backpack or can be stacked 3 high on the tube framed wheeled carrier. The shopping bags are made of materials that are easy to clean and disinfect between uses. The user can buy just the parts of the system that fits their city center lifestyle and comfortably use them to keep the dwelling stocked without requiring the use of a motorized vehicle.

Currently, when the city center dweller purchases groceries or other items, getting them home from the store can be a real problem, especially if the bags are heavy, for example, from 25 to 40 pounds each. Carrying a couple of heavy re-useable shopping bags a few blocks can cause severe fatigue of the hands and arms. Trying to do things without putting the bags down is a real issue, like, restricting placing tokens in the turnstile if the subway is used or signaling a taxi. While it is possible to mount a couple of bags on a bicycle, transporting more than that is virtually impossible.

The “Shopper’s Assistant Caddie” resolves almost all of these problems and has the added benefit of being adjusted to meet the user’s lifestyle. The standard system consists of 6 insulated shopping bags, 3 transport bags, and the wheeled carrier. Optional items are a padded strap backpack, a briefcase transport bag, and a bicycle hands free pull bar for the wheeled carrier. 2 shopping bags fit in each transport bag and up to 3 transport bags fit on the wheeled carrier. The backpack can mount and carry one transport bag at a time. The tube framed carrier’s wheels are offset and allow the transport bags to fit between them and are mounted well back of the frame to allow the fully loaded carrier to easily be pulled up the stairs of the dwelling. The carrier has a front support leg that allows the carrier to be stood upright in a crowded space like a bus, train, a subway, or an apartment elevator, taking up only about 1 additional person’s space.

The bag system is fabricated from various fabric materials. The shopping bags employ non-woven materials, are leak resistant, and are insulated to keep warm times warm and cool items cool over a reasonably long period of time. The transport bags are manufactured using durable nylon materials to withstand rough use and hold significantly large loads. The tube framed products use strong aluminum tubing, which has been colorfully anodized to complement the nylon fabric colors. The products are manufactured using, but not limited to, the following processes.

The shopping bags: These bags are cut from bolts of non-woven polypropylene plastic fabric. This fabric is very strong, allows water vapor to pass through, but will not allow the transmission of liquid water. The bolts of fabric are cut to shape a computer controlled tables using rolling cutters. After cutting to shape, the foil faced bubble insulation is adhesively bonded to the interior surface of the bag. The #10 plastic zipper is sewn to its mating surfaces for the lid and the strap handles are sewn to the interior surfaces. Then the seams are sewn to make the bag shape and then the bag is turned inside out to provide exterior finished edges and the handles are draped over the outer surface. The 0.032” thick polypropylene plastic sheet is adhesively bonded on one edge in the interior to make a durable, puncture resistant lower surface, yet the bag can still be folded flat for storage between uses. The shopping bags, when open, are 12” wide by 8” deep by 13” tall and will safely support up to 50-pound loads. Frozen materials, of a sufficient quantity, loaded into the bag will remain frozen over a 1-hour trip home.

The transport bags: These bags are cut from bolts of 600 denier, rip-stop nylon fabric. This fabric is exceptionally strong, is highly resistant to staining, tearing, and abrasion. The fabric can be supplied in one of many solid colors or can be sewn using various panels to make a patterned surface. The bolts of fabric are cut to shape a computer controlled tables using rolling cutters. After cutting to shape, the #10 plastic zipper is sewn to its mating surfaces for the fold down end and the nylon mounting straps are sewn in the proper location on exterior surfaces. Then, the seams are sewn to make the bag shape and the bag is turned inside out to provide finished exterior edges. The transport bags will accept up to two shopping bags and are 13” wide by 17” deep by 14” tall. The mounting straps are capable of 75 pounds each or 300 pounds per transport bag. The hook & loop fastener nylon web straps are sewn in a separate step and are sewn onto the transport bag using a nylon thread and cross box stitch for exceptional strength.

The briefcase carrier bag: This bag is cut from bolts of 600 denier, rip-stop nylon fabric also. The fabric can be supplied in one of many solid colors or can be sewn using various panels to make a patterned surface, matching the other bags. The bolts of fabric are cut to shape a computer controlled tables using rolling cutters. After cutting to shape, the #10 plastic zipper is sewn to its mating surfaces for the open end and the nylon mounting straps are sewn in the proper location on exterior surfaces. Then, the seams are sewn to make the bag shape and the bag is turned inside out to provide finished exterior edges. The briefcase transport bag will accept briefcases up to 18” wide by 13” tall by 5” deep.

The tubing framed, wheeled carrier: This 2-wheeled product is fabricated using 1” OD 6061-T6 bare aluminum tubing. The tubing is cut to length and robotically bent using a hydraulic bender. After bending, the 2 sections (lower frame and back) and the front support leg are robotically welded together using TIG welding techniques. After the frame is welded together, the 2” square by 3/16” thick axle support plates are welded onto the frame. The ball hitch for the bicycle pull bar is welded onto the tubing at the upper center of the tubing. After the frame is welded, it is sent out for anodizing and dying. The anodizing protects the aluminum tubing for scratches, abrasion, and corrosion. The dye can be supplied in one of 18 standard colors, allowing it to be coordinated with the bag colors. The commercially available cast aluminum wheels have high speed bearings and have 10” diameter by 2” wide pneumatic tires for ease of pulling. These are mounted in the ends of the fixed axle. As a final step the EVA foam handle is foamed in place around the upper tubing to provide a comfortable grip for pulling the carrier.

- As an option: The carrier can be attached to any bicycle using the optional ball pivot end bicycle bar. This allows the bicycle to be used to rapidly move the carrier between the store and the dwelling without requiring motorized vehicles or other public transportation.

The tube framed backpack: This backpack is fabricated using 6061-T6 aluminum tubing and uses 3” wide straps across the frame to provide support against the back. All the tubing is cut to length and robotically bent using a hydraulic bender. After bending, the backpack sections are robotically welded together using TIG welding techniques. 2 each 1” diameter tubes are welded to this frame that are the same diameter and width as the upper tubes on the wheeled carrier. This allows a single transport bag to be attached to the frame and be carried on the backpack. The comfortable nylon straps are padded and allow the heavy transport bag to be carried long distances within the city center without significant fatigue.

The “Shopper’s Assistant Caddie” is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from improved city center shopping and convenient transportation of goods, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

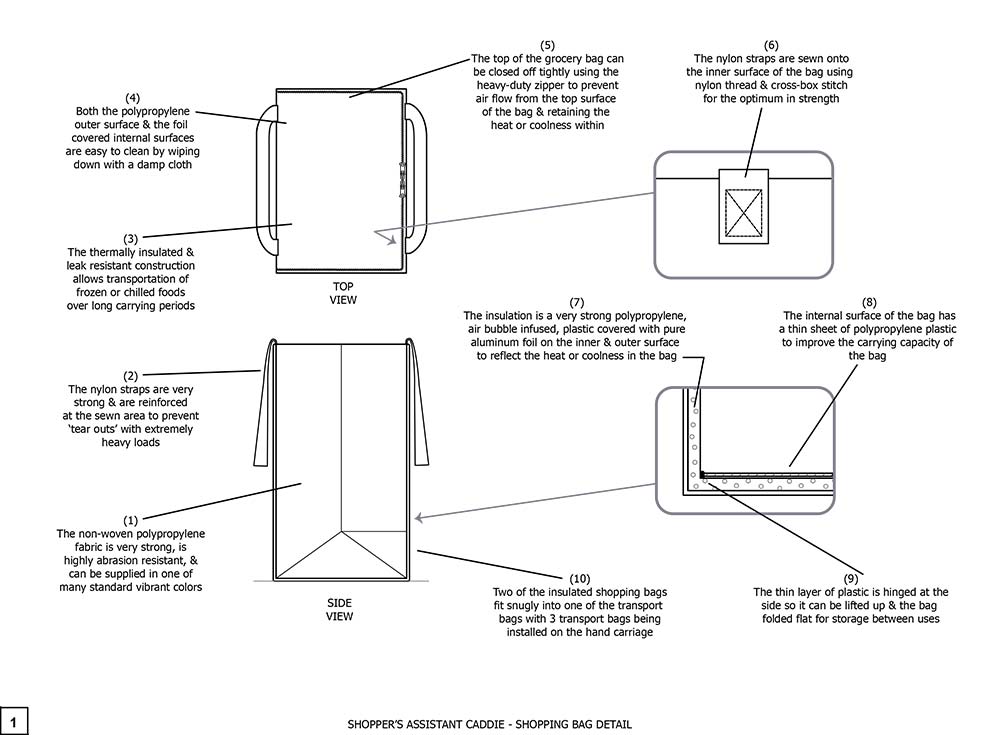

Drawing 1, Block 1: Shopper’s Assistant Caddie –Shopping Bag Detail

(1) The nonwoven polypropylene fabric is very strong, is highly abrasion resistant, and can be supplied in one of many standard colors.

(2) The nylon straps are very strong and are reinforced at the sewn area to prevent ‘tear outs’ with extremely heavy loads. Each shopping bag has been designed to hold up to 50 pounds of items without degradation.

(3) The thermally insulated and leak resistant construction allows transportation of frozen or chilled foods over long carrying periods.

(4) Both the polypropylene outer surface and the foil covered internal surfaces are easy to clean by wiping down with a damp cloth.

(5) The top of the grocery bag can be closed off tightly using the heavy-duty zipper to prevent air flow from the top surface of the bag and retaining the heat or coolness within.

(6) The nylon straps are sewn onto the inner surface of the bag using nylon thread and cross box stitch for the optimum in strength.

(7) The insulation is very strong polypropylene, air bubble infused, plastic covered with pure aluminum foil on the inner and outer surface to reflect the heat or coolness in the bag.

(8) The internal surface of the bag has a thin sheep of polypropylene plastic to improve the carrying capacity of the bag. The plastic sheet reduces the impact of sharp corners when the bag is being loaded and prevents punctures in the insulating foil.

(9) The thin layer of plastic is hinged at the side so it can be lifted up and the bag folded flat for storage between uses.

(10) Two of the insulated shopping bags fit snugly into the one of the transport bags, with 3 transport bags being installed on the hand carriage. This allows the hand carriage to transport up to 300 pounds of groceries or other items at one time.

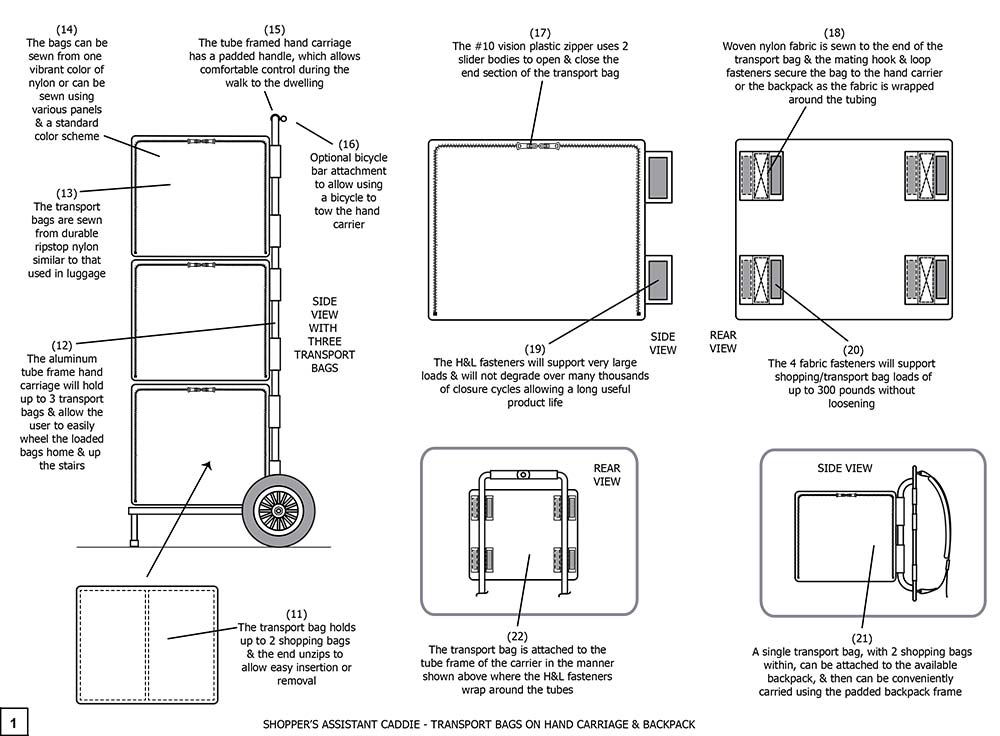

Drawing 2, Block 1: Shopper’s Assistant Caddie – Transport Bags On Hand Carriage & Backpack

(11) The transport bag holds up to 2 shopping bags and the end unzips for easy insertion or removal.

(12) The aluminum tube frame hand carriage will hold up to 3 transport bags and allow the user to easily wheel the loaded bags home and up the stairs.

(13) The transport bags are sewn from durable ripstop nylon similar to that used in luggage.

(14) The bags can be sewn from one vibrant color of nylon or can be sewn using various panels and standard color scheme.

(15) The tube framed hand carriage has a padded handle, which allows comfortable control during the walk to the dwelling.

(16) Optional bicycle bar attachment to allow using a bicycle to tow the hand carrier. This tubular aluminum product has a solid connector on the bicycle seat support and a 30° pivot on the hand carrier.

(17) The #10 vision plastic zipper uses 2 slider bodies to open and close the end section of the transport bag.

(18) Woven nylon fabric is sewn to the end of the transport bag and the mating hook & loop fasteners secure the bag to the hand carrier or the backpack as the fabric is wrapped around the tubing.

(19) The H&L fasteners will support very large loads and will not degrade over many thousands of closure cycles allowing a long useful product life.

(20) The 4 fabric fasteners will support shopping/transport bag loads of up to 300 pounds without loosening.

(21) A single transport bag, with 2 shopping bags within, can be attached to the available backpack, and then can conveniently carried using the padded backpack frame.

(22) The transport bag is attached to the tube frame of the carrier in the manner shown above where the H&L fasteners wrap around the tubes.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.