Self-Inflating Air Bed

DESCRIPTION:

The air mattress or air bed has been utilized for sleeping since the early 1400’s, and the materials used then were crude and not very effective. The early fabrics, animal skins or other materials did work if only for short periods of time. The materials were troublesome and tended to deteriorate and lose air. The comfort they provided was noted, and in more recent times the air bed has enjoyed a renewal in its popularity. The air mattress or air bed has support qualities that lend itself to people who have back problems or similar issues. Adjustable air pressure in the air mattress enable the bed to be soft or firm and is adjusted to suit an individual’s needs.

The air mattress is lightweight and in its uninflated form is compact and easily transported. There are purposely intended air mattresses for backpacking and camping that are of reduced thickness and often have an integrated foam insulation added under the air chambers. Air beds that are designed for use in the home are manufactured with comfort and portability in mind and making them lightweight is not as much a priority as those that have to be carried by individuals on camping or hiking trips. Various sizes and styles are available for the consumer on the open market. These air beds range from a single sleeper to the sophisticated large double beds and even go as large as king size for deployment in the home or away from home situations where a portable bed is needed.

The air bed has even made it into mainstream mattress manufacturers and is set up as a permanent bed in homes and establishments such as hotels, etc. The permanent air bed has the advantage of being able to adjust its firmness with just the touch of a button. The firmness is adjustable for individual sides of the bed in most cases making it ideal for couples.

Typically, most air beds are seen as a temporary solution to situations where sleeping accommodations are not available. The portability and comfort of an air bed is a desirable alternative in these circumstances. Emergency situations where people are displaced from their homes an air bed can add extra comfort to a stressful situation.

One of the major issues with air beds is the difficulty of inflating the bed. Pumps can be used but are often not available in many situations and inflating an air bed manually is an exhausting process and not always possible especially if the bed is large or has multiple chambers that need to be filled with air.

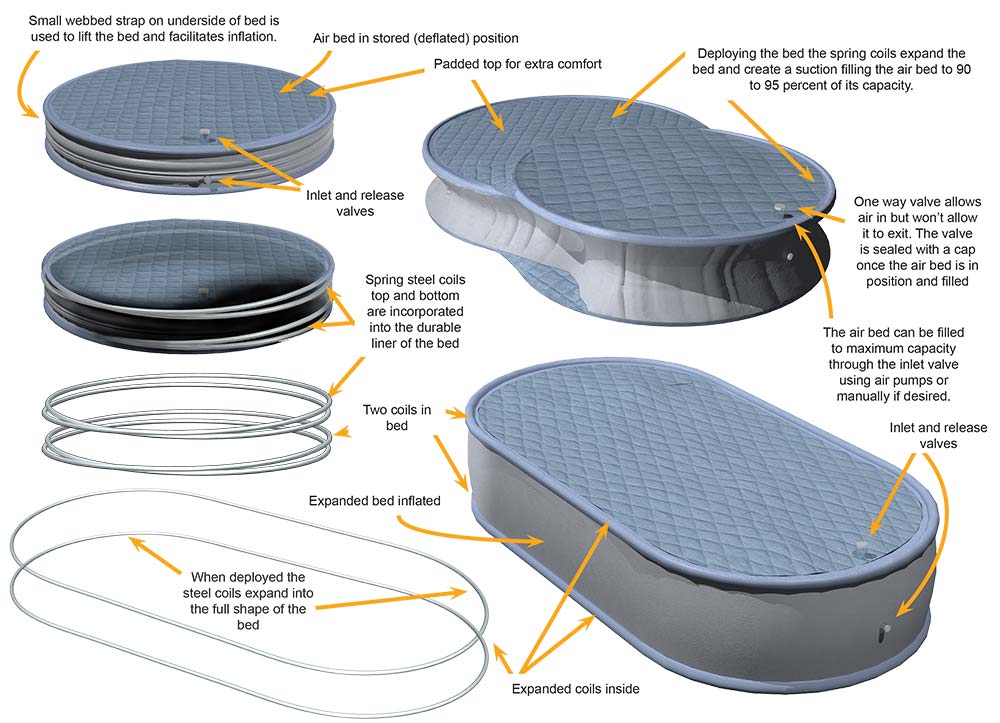

The Self-Inflating Air Bed is a unique and innovative solution to the inflation issues associated with air beds. The Self-Inflating Air Bed utilizes the strength and power of a coiled steel spring that is incorporated into the fabric of the Self-Inflating Air Bed. The coil spring is located on the outer rim of the air bed and when in the stored and deflated position takes a minimum amount of space and is lightweight. When the Self-Inflating Air Bed is deployed the steel coil spring is expanded out to produce the full shape of the air bed. A small webbed strap located on the underside is used to lift the bed and facilitate inflation. The strength of the expanding coils creates a vacuum in the chamber of the Self-Inflating Air Bed. The vacuum will draw air into the body of the air bed through a one-way valve located on the top edge of the air bed. The total air volume drawn into the air bed is about 90 to 95 percent of the total volume needed to fill the bed. The bed is fully functional at that point but can be topped off with a pump or manually if desired. A release valve is located on the side of the bed for deflating. The Self-Inflating Air Bed saves time and effort filling the bed with air. The Self-Inflating Air Bed is ideal for situations where an air pump is not available, or manual inflation is not possible or desired. Military, emergency applications, travel, temporary housing, recreation and many other uses the Self-Inflating Aid Bed will prove itself indispensable.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Compact and lightweight

- Easily deployed by one person

- Webbed strap on underside to lift bed and facilitate inflation

- Spring coils expand to create vacuum to fill bed

- Coils easily return to original position when deflated

- Self-inflates up to 95% of maximum capacity

- One-way inlet valve keeps drawn in air in

- Release valve on side for deflation

- Durable materials and reusable

- Ideal for emergency situations, recreation or extra bed

- Padded top for extra comfort

- Additional air can be added with pump or manually

- Deflates to space-saving size

PRODUCT COMPONENT CLARIFICATION:

The “Self-Inflating Air Bed” is an innovative sleeping and rest product that has been designed to provide an additional sleeping mattress that is very simple and easy to set up or deflate and store. The air mattress is self-inflating and does not require an air pump to fill. When deployed, the mattress is almost the same size as a queen, and its patterned, flocked top provides extra comfort during use. The waterproof fabric is easy to clean and will not absorb moisture or odors. After use, the bed can be deflated and with a twist of the wrists, transforms into a thinner circular outline for easy storage until the next use.

Currently, when additional sleeping surfaces are required, the air mattresses are dragged out, unfolded, the air pump found, and then the bed is inflated. Often the air pump cannot be located, or when deployed for use, the cord is tangled, making the use very irritating. If the pump is battery powered, often the battery needs to be re-charged before use, providing additional irritant. If the pump cannot be found or is not working, manually inflating by mouth or hand pump is a very arduous.

The “Self-Inflating Air Bed” resolves almost all of these problems by easily inflating itself to about 90% full without requiring any external pump. The product is stored in a circular condition and then can be untwisted to make a large oval, which is then pulled upward allowing ambient air to flow into the bed through a check valve as it expands. After the bed fills, it can support two adult people comfortably. The hypoallergenic plastic fabric is very durable with the upper and lower surfaces textured for additional comfort. The spring steel coils at the periphery provide additional support at the edges. If rough use causes a leak to occur, the product is supplied with a patch kit to take care of this problem. The fill is permitted through the large Boston style valve, which has a cap to further seal the chamber after inflation. The mattress can be emptied of air in a few minutes through the cap seal valve on the end. The mattress is supplied in a standard gray color but can also be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product.

The mattress: The mattress is fabricated using the following materials. Other materials can be substituted if the manufacturer would prefer working with them.

- The plastic fabric: This fabric used in the construction is very high-quality polyvinylchloride (PVC) fabric. This fabric is supplied in 2 thicknesses and textures. The side panel is 16 mils thick and the upper and lower fabric layers are 24 mils thick. The upper and lower fabric layers are textured (flocked) on one side, which is turned outward when the mattress is fabricated. The sheets of PVC fabric are cut to shape using a water jet machining center. After cutting to shape, they are rinsed, dried and then thermally bonded around the spring steel coil and together to make the airtight mattress chamber. The thermal welds are very strong, providing a very long product life during normal use. The PVC fabric is flexible, is impervious to household chemicals, resists punctures, is waterproof, and is easy to clean.

- The nylon web strap: This strap is adhesively bonded to the outside of the lower surface of the mattress. This strap allows the mattress to be expanded more vigorously so it inflates quicker and also serves as a handy carrying handle when the product is collapsed for storage.

- The steel coils: These steel coils are supplied using high carbon steel wire that is oval in shape with the thickness about 0.070” and the height about 0.125”. The ends of the wire are thermally bonded using resistance welding. The welds have the same strength as the parent material so there are no weak spots in the coils. These wires are covered with the fabric, which is thermally welded around them to secure them in place and still make an airtight bladder for the mattress. There are 2 rings per mattress and they are restrained in shape by the tension of the fabric when the mattress is fully inflated.

- The inlet valve: This valve is similar to the common Boston valve used in all sorts of inflatable devices, including most air mattresses. These valves are one-way units that allow air in only and have sealing caps that screw over the valve, providing a redundant seal to prevent inadvertent leaks.

- The bleed valve: This valve has a tethered cap that is screwed down against the tube end and compresses an internal O-ring to seal the vessel. When it is removed, it allows the internal air to flow out rapidly. The deflating process is accelerated when a weight is placed upon the mattress or the bands are twisted, folding it into the compact form, compressing it to force the air out,.

The Self-Inflating Air Bed is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from easy set up and storage while providing a very comfortable sleeping surface, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

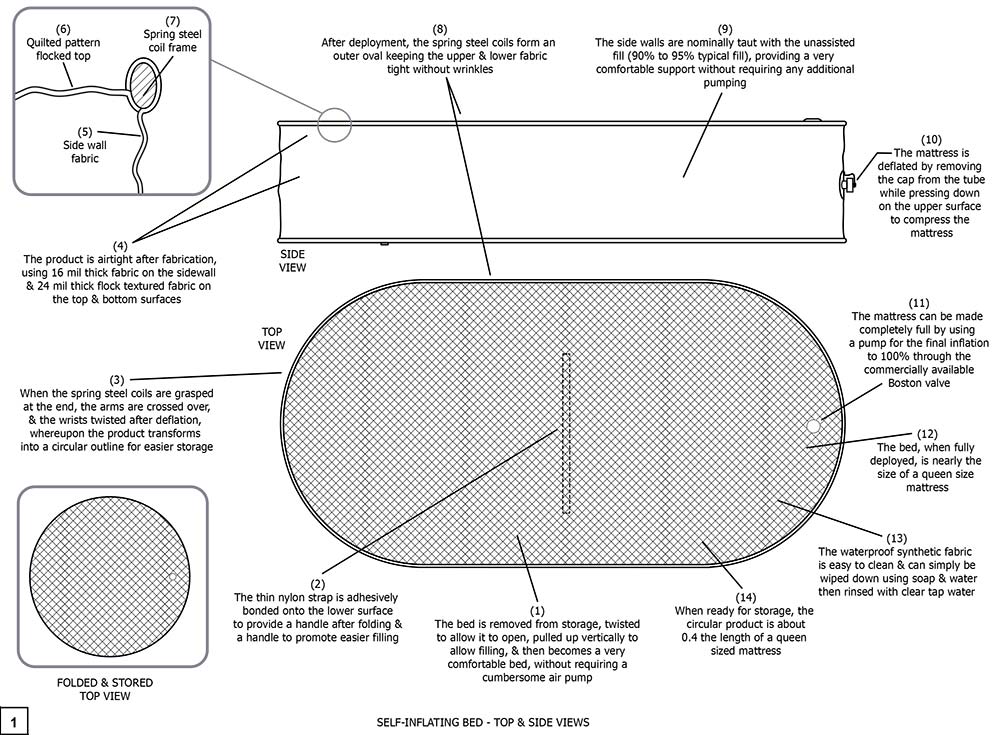

Drawing 1, Block 1: Self-Inflating Bed – Top And Side Views

(1) The bed is removed from storage, twisted to allow it to open, pulled up vertically to allow filling, and then becomes a very comfortable bed, without requiring a cumbersome air pump.

(2) The thin nylon strap is adhesively bonded to the lower surface to provide a handle after folding and a handle to provide easier filling. The user can place their foot on the strap when pulling up on the upper coil providing a bit of leverage to enhance the incoming air flow through the one-way valve.

(3) When the spring steel coils are grasped at the end, the arms are crossed over and wrists twisted after deflation, whereupon the product transforms into a circular outline for easier storage.

(4) The product is airtight after fabrication, using 16 mil fabric on the sidewall and 24 mil thick fabric on the top and bottom surfaces.

(5) Side wall fabric

(6) Quilted pattern flocked top

(7) Spring steel coil frame

(8) After deployment, the spring steel coils form an outer oval keeping the upper and lower fabric tight without wrinkles.

(9) The side walls are nominally taut with the unassisted fill (90% to 95% typical fill), providing a very comfortable support without requiring any additional pumping.

(10) The mattress is deflated by by removing the cap from the tube while pressing down on the upper surface to compress the mattress.

(11) The mattress can be made completely full by using a pump for the final inflation to 100% through the commercially available Boston valve.

(12) The bed, when fully deployed, is nearly the size of a queen size mattress.

(13) The waterproof synthetic fabric is easy to clean and can simply be wiped down using soap and water then rinsed with clear tap water. Then it can be allowed to air dry or an be toweled dry.

(14) When ready for storage, the circular product is about 0.4 the length of a queen sized mattress.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.