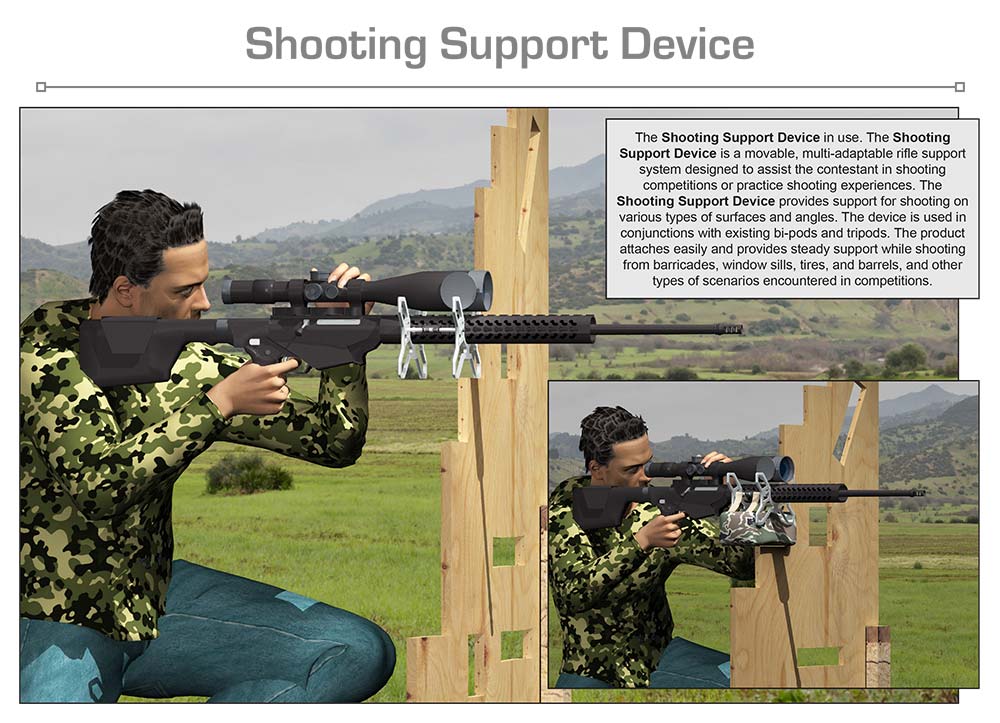

Shooting Support Device

DESCRIPTION:

Competition shooting as an amateur and professional sport has existed since the introduction of the firearm. Ancient people competed with archery and implements as crude as the atlatl and spear for accuracy and distance. Black powder weapons appeared in the 9th century in China and spread throughout most of Eurasia by the 13th century mostly as an explosive and for rockets and cannons. The hand weapons were developed later when metalworking technologies reached a sufficient level to make a hand-carried gunpowder weapons a feasibility. Early matchlock weapons were introduced in the 1500’s as hand-carried weapons but were crude and manufactured with metals that performed poorly such as bronze and cast iron. These early guns were often as dangerous to the user as their opponents.

The technological breakthrough of the grooved or rifled barrel and high-quality steel production increased the reliability and accuracy of the rifle to the point that competition shooting became a much more demanding sport among enthusiasts. The range and ability to hit the target at increased distances added to the challenge of shooting competitions. High-quality and extremely accurate guns introduced to the sport meant that the contest relied solely on the skill of participant and anyone who was physically capable of holding a weapon could compete. Men, women and young people could compete on an equal status as the weight and bulk of the weapons continued to decrease. Weapons manufacturers are producing a great variety of high-quality guns, and almost any amount of money is spent on the weapons and equipment involved depending on the individual. The guns produced are in different calibers for different types of shooting and assortments of loading systems and operating methods. The activity of competition shooting has evolved into a highly competitive sport, and it involves many different scenarios that include time and accuracy for the competitor as well as physical trials while completing courses.

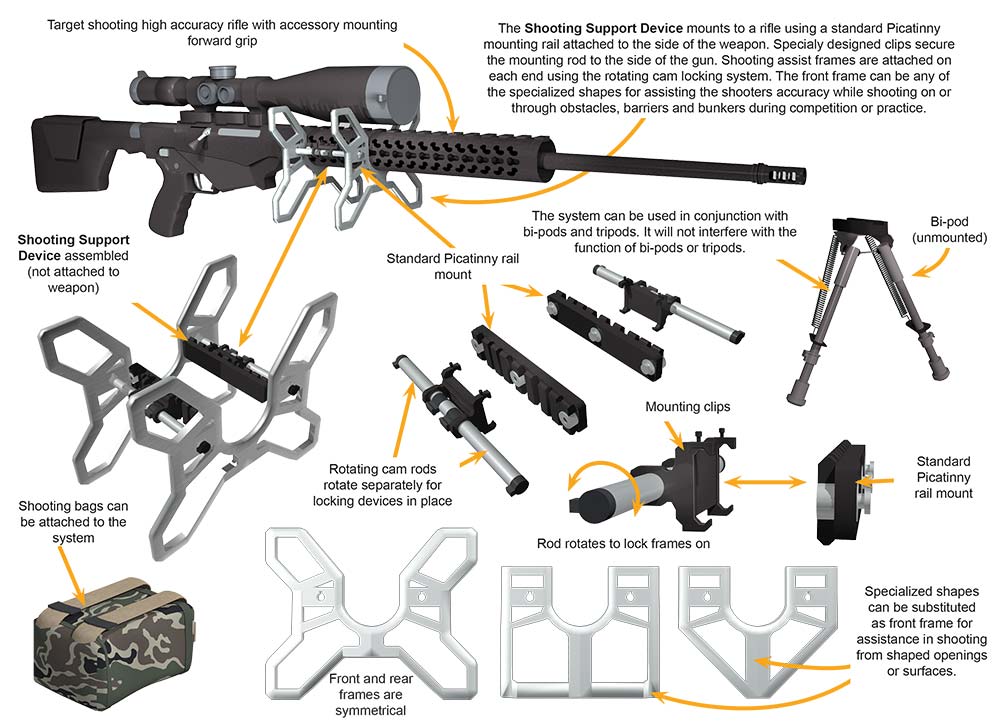

The Shooting Support Device is a system that is designed to assist the competitive shooter in accomplishing and scoring in shooting trials and competitions. A movable and adaptable rife support system the Shooting Support Device is easy to attach and remove whenever desired. The System provides support for shooting on various surfaces and at multiple angles. The product attaches to the rifle on the fore stock grip of the gun utilizing a standard Picatinny rail system. The attachment rail located on the side of the forward grip provides the Shooting Support System an attachment point for the quick connect mounting clips. Mounted on each set of quick connect clips is a rotating rod. Each rotating rod has on each end a locking cam that will hold the steadying frames that will lock on to the rifle using the mounting hardware described. The rods will rotate independently so that the fore and after frames can be locked or removed separately. Once the frames are locked onto the stock, they will provide continuous support for any shooting position and for a multitude of surfaces that might be encountered. Specialized frame shapes are available for the front frame position that will make the support provided by the Shooting Support Device even more efficient in certain circumstances. The standard bi-pods and tripods that are typically attached to the underside of the forward stock grip can be used in conjunction with the system and will not interfere with the function of the product if left in place. Shooting bags that are used to assist the placement and aiming of the rifle can be attached to the system as an option. The entire system is lightweight and will support the rifle in almost any shooting scenario. The Shooting Support System will enhance the shooter ability to support their rifle and increase their scores in competitive rifle shooting events.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Lightweight and compact

- Durable construction and long service time

- Assists the support of a rifle during shooting event

- Easy and quick to attach and remove

- Can be used in conjunction with bi-pods and tripods

- Increases accuracy and reduces time spent positioning rifle

- Can be used with shooting bags

- Quick connects to rifle stock

- Different forward support frame variations available

- Cam operated connect system for attaching support frames

- Uses standard Picatinny rail system for mounting

PRODUCT COMPONENT CLARIFICATION:

The “Shooting Support Device” is an innovative long-distance shooting (LDS) rifle accessory product that has been designed to provide support to the weapon during use. The product attaches to the quad rail handguard of the rifle and is secured using 4 knurled knobs, which compress a pair of Picatinny clamps. The invention can then be placed upon any convenient support where the bi-pod or sand bag may not work or be effective. The support product can easily be removed or exchanged with a different shaped support that will provide the steady rest on an unusual shaped surface. The metal product is compact, lightweight, and can easily be stored in the range bag between uses.

Currently when shooting long distances, a steady rest is required to allow the rifle to aimed and shot effectively. People who engage in long distance shooting rely most often on a mono-pod, a bi-pod, or on a sandbag as a steady rest. These typically work well, but sometimes they just are not the optimum rest to use because of the underlying support or terrain they need to sit upon. Not having the optimum rest complicates the shot, which can lead to reduced accuracy. Also, as we age, essential tremors can affect our sight picture and the commonly available supports are not effective or are too heavy to bring along.

The “Shooting Support Device” resolves almost all of these issues. The easy to attach aluminum alloy invention is lightweight and when mounted does not affect the mounting of other steady rests, like the bi-pod. The product is designed to work with either Weaver or Picatinny handguard rail systems but is optimized to fit onto the handguard of an LDS rifle with Picatinny quad rails. The machined end sections are held together with high-strength fasteners, which are reinforced with thread lock adhesive. The rail clamp is solid and designed to eliminate any rotation or flexing once clamped in place. The knobs have nylon inserts and resist loosening even when the invention is used on very large caliber rifles. The product is anodized to provide a durable scratch and corrosion resistant surface. The anodize can be dyed to provide an attractive product or can be satin dark color to reduce visibility. One of the standard color combinations is royal blue end sections, with purple reinforcing rods, and satin black rail clamps. After use, the compact product can quickly be removed and stored in the range bag until the next requirement.

- As an option, the invention can be supplied with various end section shapes, which can conform better to the terrain or unusual shaped support the rifle is resting upon.

The end sections: These end sections are water jet machined from 0.25” thick sheets of 6061 alloy aluminum. The water jet can create almost any shape that can be conceived. The machining removes about 1/2 of the material, which dramatically reduces the weight while retaining the strength. The optimum shape is developed in the following illustration, but almost any shape can be supplied by the manufacturer. After machining, the product is subjected to vibrational deburring, taking the sharp edges off the machined shape so it feels more comfortable to the hand. After deburring, the product is cleaned, anodized to improve resistance to scratching, and then is dyed in one of many vibrant colors.

The reinforcing rods: These rods are turned to length, are drilled and tapped on a CNC lathe from 0.25” diameter, 6061 alloy rod stock. After machining, the product is subjected to vibrational deburring, taking the sharp edges off the machined shape. After deburring, the product is cleaned, anodized to improve resistance to scratching, and then is dyed in one of many vibrant colors.

The rail clamps: These rail clamps are designed to work with either Weaver or Picatinny mounting rails but are optimized to work best on the Picatinny system. The clamps are machined from 6061 aluminum alloy sheet and bar stock on a CNC machining center. The base section is drilled and tapped to be secured to the end sections using 10-32 screws. The upper clamp section is supplied with 2 through holes to accept the 10-32 studs mounted in the base sections. When the upper section is separated about 0.100”, the Picatinny clamp is fully seated on the handguard other rail. After machining, the product is subjected to vibrational deburring. After deburring, the product is cleaned, anodized to improve resistance to scratching, and then dyed in one of many vibrant colors.

The socket head, flathead screws: These screws are commercially available 10-32 high-strength steel screws. These screws are secured in the assembly using permanent thread locking adhesive.

The clamping knobs: These 6061-aluminum alloy, commercially available, knobs are turned on a CNC lathe and then drilled to accept a nylon locking insert. This insert prevents the knob from loosening caused by shock and vibration of firing a high-power rifle, even very large calibers, yet will permit quick removal of the clamp from the handguard when desired.

The aluminum sub-components can be anodized and dyed in almost any vibrant color, so a distinctive color, or colors, may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. These are, but not limited to, the following.

| Standard Colors | ||

|---|---|---|

| Black | Gray | Bronze |

| Gold | Royal Blue | Navy Blue |

| Purple | Red | Green |

| Teal | Orange | Pink |

| Turquoise | Clear (Silver) |

| Other Standard Colors | ||

|---|---|---|

| Flat Black | Satin Black | Satin Gray |

| Desert Tan | Olive Drab | Gun Blue |

| Stainless Steel | Satin Stainless | Dark Gray |

The Shooting Support Device is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from improved stability during shooting and ease of use with other rests, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

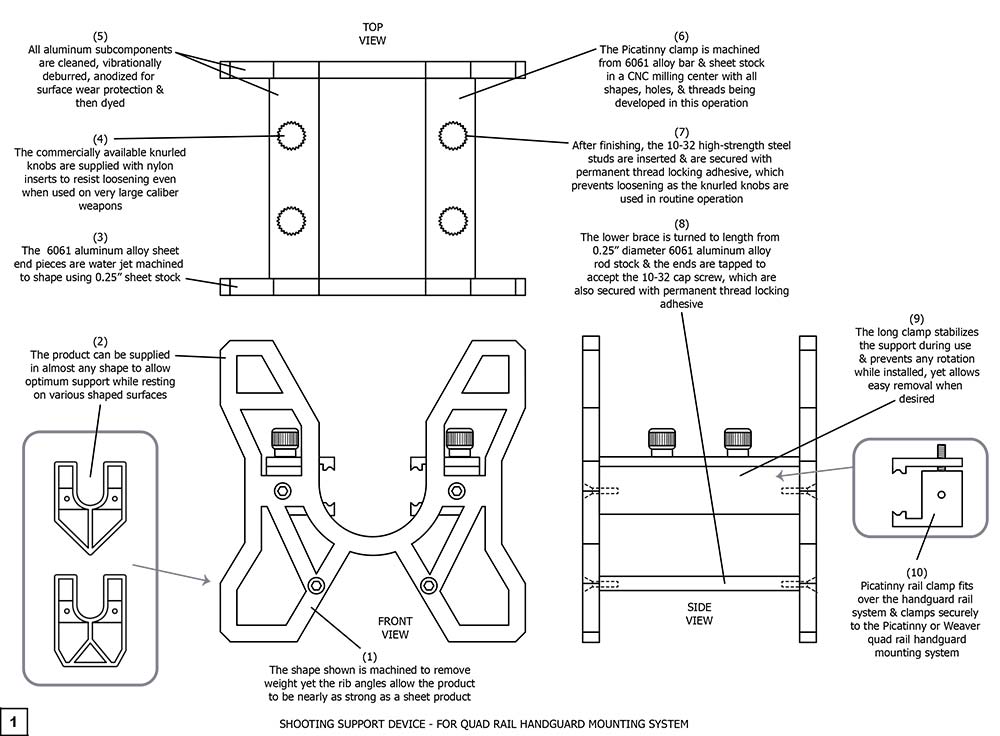

Drawing 1, Block 1: Shooting Support Device – For Quad Rail Handguard Mounting System

(1) The shape shown is machined to remove weight yet the rib angles allow the product to be as strong as a sheet product.

(2) The product can be supplied in almost any shape to allow optimum support while resting on various shaped surfaces.

(3) The 6061 aluminum alloy sheet end pieces are water jet machined to shape using 0.25” sheet stock.

(4) The commercially available knurled knobs are supplied with nylon inserts to resist loosening even when used on very large caliber weapons.

(5) All aluminum subcomponents are cleaned, vibrationally deburred, anodized for surface wear protection, and then dyed.

(6) The Picatinny clamp is machined from 6061 aluminum bar and sheet stock in a CNC milling center with all shapes, holes, and threads being developed in this operation.

(7) After finishing, the 10-32 high strength steel studs are inserted and secured with permanent thread locking adhesive, which prevents loosening as the knurled knobs are used in routine operation.

(8) The lower brace is turned to length from 0.25” diameter 6061 aluminum alloy rod stock and the ends are tapped to accept the 10-32 cap screw, which are also secured with permanent thread locking adhesive.

(9) The long clamp stabilizes the support during use and prevents any rotation while installed, yet allows easy removal when desired.

(10) Picatinny rail clamp fits over the handguard rail system and clamps securely to the Picatinny or Weaver quad rail handguard mounting system.

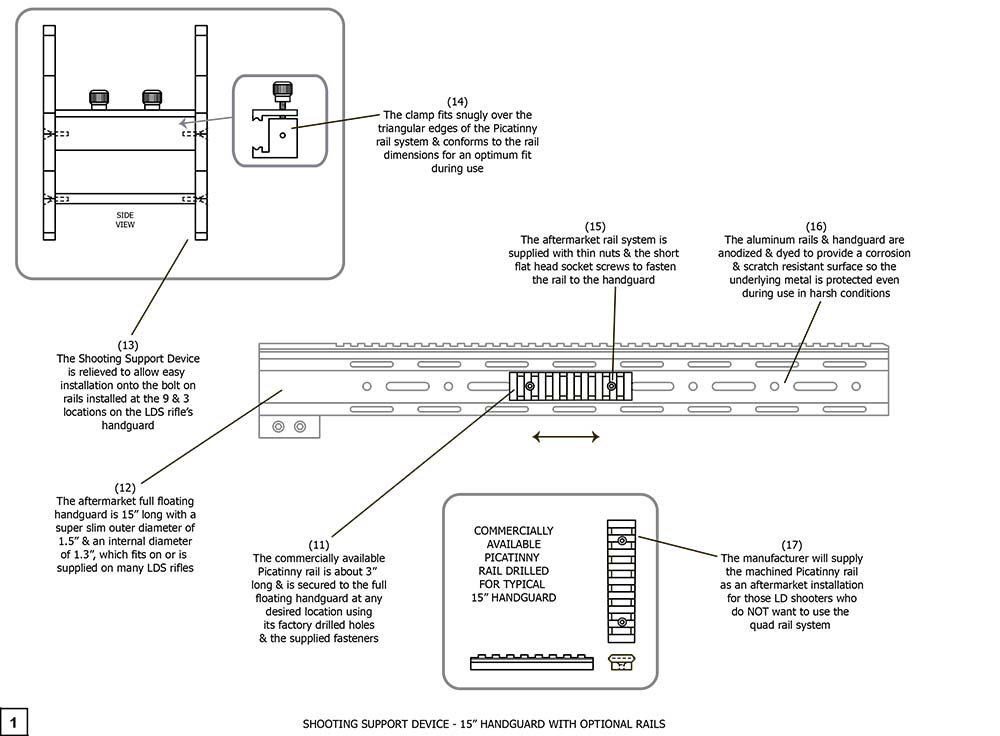

Drawing 2, Block 1: Shooting Support Device – 15” Handguard With Optional Rails

(11) The commercially available Picatinny rail is about 3” long and is secured to the full floating handguard at any desired location using the factory drilled holes and the supplied fasteners.

(12) The aftermarket full floating handguard in 15” long with a super slim outer diameter of 1.5” and an internal diameter of 1.3” which fits on or is supplied on many LDS rifles.

(13) The Shooting Support Device is relieved allow easy installation onto the bolt on rails installed on the LDS rifle’s handguard.

(14) The clamp fits snugly over the triangular edges of the Picatinny rail system and conforms to the rail dimensions for an optimum fit during use.

(15) The aftermarket rail system is supplied with thin nuts and the short flat head socket screws the fasten the rails to the handguard. After assembly, the distance between the currently supplied quad rails handguard system at 9 and 3 o’clock positions are the same as those when these aftermarket rails are bolted onto a 1.5” OD handguard.

(16) The aluminum rails and handguard are anodized and dyed to provide a corrosion and scratch resistant surface so the underlying metals is protected even during use in harsh conditions.

(17) The manufacturer will supply the machined Picatinny rail as an aftermarket installation for those LD shooters who do NOT want to use the quad rail system.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.