Stadium Seat Table

DESCRIPTION:

The oldest known stadium resides in Olympia in western Peloponnese, Greece. The stadium was the site for the ancient Olympic games that were held around 776 BC. The Greek stadium is not as large or as grand as the Roman Coliseum but does have the distinction of preceding the coliseum by almost a millennium. The Roman Coliseum was completed in 80 AD by emperor Titus. The capacity of the coliseum in its day could hold a respectable 50 to 80 thousand spectators. An ability that can rival many modern-day stadiums. Regardless of the locations, stadiums and amphitheaters have been in use to host a vast variety of events for many centuries.

Stadiums in the modern era were first built as basic facilities designed to hold as many people as possible. Organized sport in the Victorian era became very popular with football in the United Kingdom and baseball in the United States creating the most interest. An early stadium was the Lansdowne Road Stadium built in 1872. In the United States, many baseball teams built stadiums mostly out of wood. The wood stadiums were a fire hazard, and many did burn as a result. Those parks that were not destroyed soon proved inadequate and were replaced by more modern structures. The construction of large arenas and stadiums continues and are used for a variety of events.

The spectators attending the events at stadiums have always needed food and drink ever since the concept of the stadium was introduced by the Greeks for their games. The recent phenomenon of tailgating is probably not a recent event although the tailgate doubtless is. The Greeks and Romans were probably outside the stadium eating food and drinking beverages just as it’s played out today in most of the popular stadiums. The Majority of modern stadiums have vendors that serve food and drinks to spectators once inside the arena. Security concerns and other considerations prevent most events not to allow spectators to bring their food and drink into the stadium. Spectators now are required to purchase their beverages and food at the on-site vendors and take the items back to their seats. Once a spectator has their beverages and food in hand, and back at their position, another problematic issue becomes apparent. Due to the limited area of stadium seating, finding a spot to place the food and drink becomes a real issue. Many people set their drink on the floor next to their seat only to be accidentally kicked over and spilled by people traversing through the walkway and seats or forgotten about and knocked over by themselves. Food usually winds up in the person’s lap or held in the hand until consumed or disposed of. Eating and drinking at a sporting or other popular event is a challenge that few people can navigate without some difficulty.

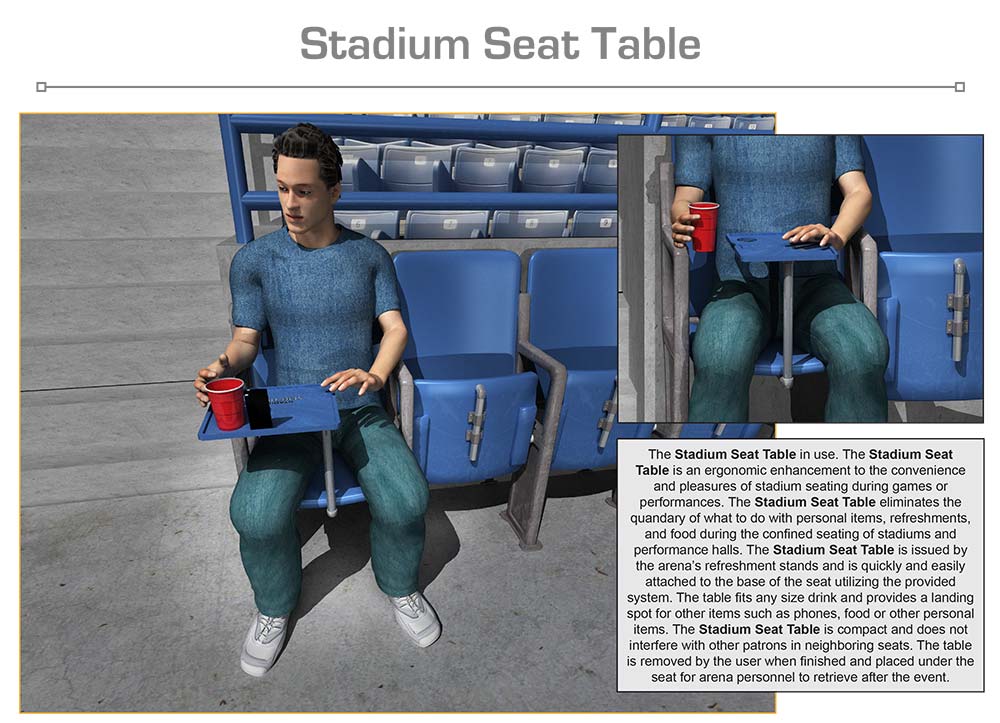

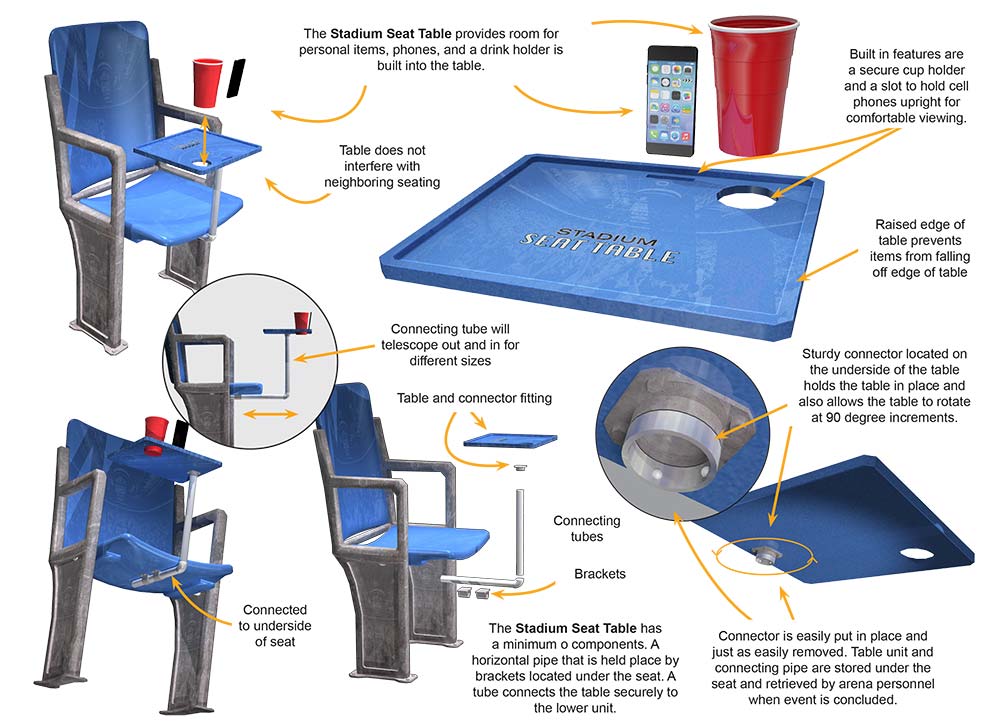

The Stadium Seat Table is a unique and innovative solution to eating and drinking issues during the big event at a stadium. The patron purchases beverages and food at the concession stand and the server will serve the food and drink on or with the Stadium Seat Table. The table will hold the drink securely via the provided cup holder or hole in the table. The cup holder will keep the drink secure to the table to prevent jostling or spilling. The food is kept on the top of the table, and the raised edge will prevent anything from sliding off and getting ruined during the trip back to the seat. The Stadium Seat Table has other features such as a slot to hold cell phones upright and in front of the user. Once back at their seat the person will connect the table to a tube that is connected to a mechanism fastened to the bottom of the seat. The table is fitted to the extension tube with the connecting piece fitted to the underneath side of the table. The underside table fitting is offset to allow the product to be to either the right or left of the user. The connecting tube will also telescope out to allow different size guests to be accommodated. The table will also rotate at 90 degree increments for different positions. The table will not interfere or block any neighboring seats. The patron now has the product situated right in front of them and is ready to enjoy the event without worrying where to put all of the expensive food and drink that was purchased. Once the event is over or the patron has finished with the table the Stadium Seat Table can be removed and placed under the seat for the stadium personnel to retrieve when the event is concluded.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Provides convenient landing spots for food, drink, and personal items

- Table is distributed with food and drink from concession stands

- Holds drink and items securely

- Simple mechanism for attaching table to seat

- Table will rotate with locking mechanism at 4 points

- Support tube will telescope out and in for different size users

- Table removed and placed under seat and out of the way when finished

- Slot for holding cell phone

- Table is retrieved after event by stadium personnel

- Easy and quick to attach and remove

- Quality and durable materials

- Variety of designs and colors available

PRODUCT COMPONENT CLARIFICATION:

The “Stadium Seat Table” is an innovative ball park product that has been designed to dramatically improve the safety and convenience of eating and drinking at any stadium seating. The product is an 8” by 12” food grade plastic serving tray that sits on a tubing riser near the left side of the seat. This tray can be rotated and locked into any one of 90° increments with the primary location being parallel with the walkway in front of the seat with the drink and cell phone holder away from the user. After use, the tray can be removed from the riser assembly and returned to the concession stand using the attendants or it and the riser tubing can be stored under the seat until further use. The food grade trays can be machine washed, air dried, and then stacked in the concession stand for storage. The riser assemblies remain with the seat, ready for the next use.

Currently, the user visits the concession stand and is given the food and drink as individual servings to carry back to the designated seat and consume. Juggling 2 or more items while walking up or down steep stairs to the seat with the hands full can be a daunting task, especially if you are young, old, or are even slightly disabled. If the buyer is getting multiple drinks and food for several people, they may be given a flimsy cardboard tray for transportation back to the seat. If the cardboard carriers are not supported with 2 hands, the cardboard carriers can droop, spilling the beverages or the food before the fan can get back to the seat. If the fan has to hold onto the railing with one hand to negotiate the stairs, they can lose a significant part of their purchase before they can get back to their seat or irritate other fans if the food or drink is spilled upon them.

The “Stadium Seat Table” resolves most of these problems by providing a reusable, heavy duty plastic tray that can be used to safely transport drinks and food back to the user’s seat. The rugged yet small tray can be carried with one hand on any of the 4 edges and will remain rigid, conveniently transporting the food and drink without spillage. Upon arrival at the seat, the tray can be mounted on the riser assembly and adjusted to provide optimum support of the user’s food, drink, and cell phone. The 16-ounce drink cup fits in the 3.25” diameter cup recess where it can easily be retrieved but cannot easily be knocked over. The cell phone can be placed on end near the front edge of the tray so the user can observe any streamed content ‘hands-free’. When the user is finished, the tray can either be stored under the seat for after game pick up or can be returned to the roving attendant so it can be taken back to the concession stand. There it can be machine washed, air dried, and stacked in a sanitary cabinet for the next use. The riser tubing is compactly stored under the seat until required for the next use.

The seat brackets: The two brackets are stamped from 6061 aluminum alloy, 12 gauge (0.081”) thick, sheet stock. The brackets are stamped to accept the 1.50” square outer tube of the riser assembly in a loose but snug fit. They are secured to the pivoting plastic seat base using oval head carriage bolts. The brackets are offset to the near left side of the seat to allow the riser to rest against the side of the user’s leg, when installed, and permit the user to stand when the tray is rotated outward 90°.

The support tubing: This tubing is designed to fit snugly within the seat brackets. It consists of 6005A-T6 aluminum alloy, 1.25 OD and 1.50” OD extruded square tubing with 0.020 wall thickness. The 1.25” tubing is snug loose fit within the 1.50” tubing and slides in and out smoothly. The outer tube is drilled and the inner tube employs a spring-loaded button to secure the two tubes at any extended position. The riser assembly has a right-angle fitting that is 1.25” ID and the tray fitting has a rectangular locking plate attached to the rotating fitting. Each of these are manufactured using various aluminum alloys.

- The angle bracket: This is cast using A356 aluminum alloy in a permanent mold. The drive pin holes are drilled post casting. This angle fitting accepts the 1.25” connector tubing and is pinned to the horizontal tubing, while accepting the vertical tubing.

- The tray bracket: This bracket is manufactured in 3 pieces using A356 aluminum alloy. The retaining plate is stamped from 6061 aluminum alloy sheet and is then secured to the cast outer ring using spool gun MIG welding. The cast inner ring is secured to the square tubing connector using the MIG welding techniques. The outer ring’s interior surface is slotted to accept a snap ring to hold the two rings together and allow them rotate independently. The outer ring is drilled in 4 places (or more) to accept the spring-loaded rotation button mounted on the inner ring, locking them in place yet is easy to reach under, depress, and rotate the tray.

The aluminum sub-components: After assembly, each of the aluminum components are vibrationally deburred, cleaned, anodized, and dyed. The anodize hardens the aluminum surface to provide a scratch resistant surface during use. The dye can match the team’s colors, or can contrast to them, depending upon the designer’s choice.

| Standard Anodize Colors | ||

|---|---|---|

| Black | Gray | Bronze |

| Gold | Royal Blue | Navy Blue |

| Purple | Red | Green |

| Teal | Orange | Pink |

| Turquoise | Clear (Silver) |

The serving tray: The commercially available, 12” wide by 8” deep by 1” high, serving tray is injection molded from food grade polypropylene plastic. This food grade, BPA free, plastic is very durable, is nearly impervious to household and cleaning chemicals, is highly resistant to UV degradation, and is typically used in this type of application. The trays can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The food tray is purchased with a cell phone stand, a drink holder for 16-ounce plastic cups, and an adhesively bonded offset mounting bracket underneath. The trays are normally supplied in one of 14 standard colors or can be supplied in a special-order color. These standard colors are as follows.

| Standard Colors | |||

|---|---|---|---|

| Beige | Black | Blue | Burgundy |

| Café Teal | Chocolate | Forest Green | Gold |

| Gray | Green | Light Brown | Orange |

| Red | Slate Blue |

The Stadium Seat Table is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from improved transportation, use, support of the purchased items plus the cell phone for viewing any streamed content of the game being attended, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

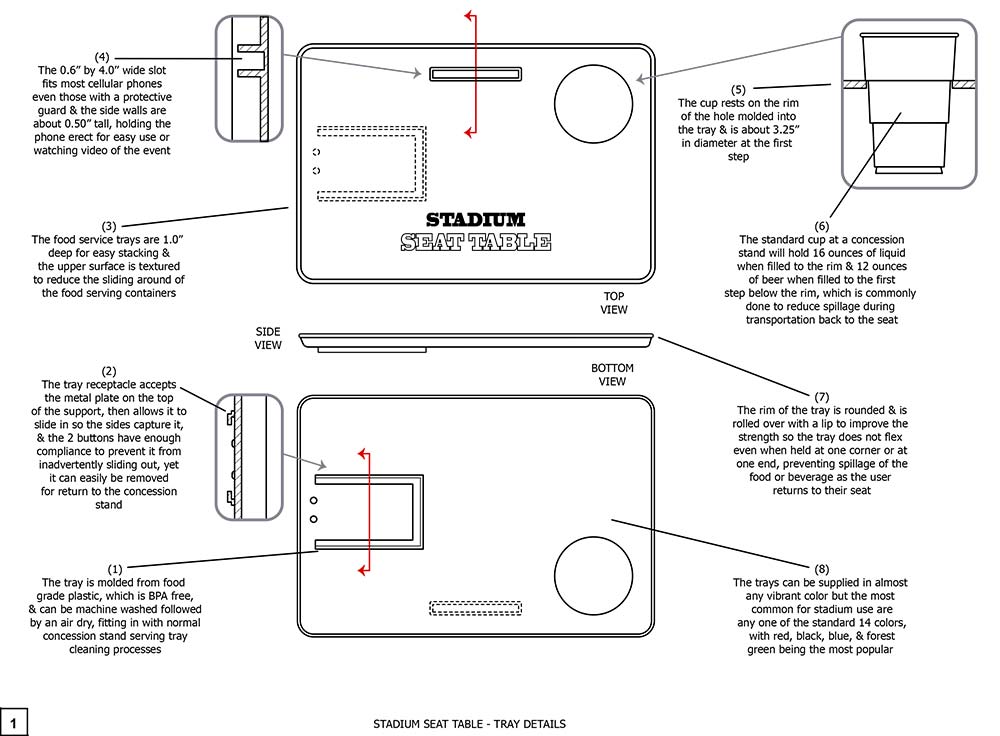

Drawing 1, Block 1: Stadium Seat Table – Tray Details

(1) The tray is molded from food grade plastic, which is BPS free, and can be machine washed followed by an air dry, fitting in with normal concession stand serving tray cleaning processes.

(2) The tray receptacle accepts the metal plate in the top of the support, then allows it to slide in so the sides capture it, and the 2 buttons have enough compliance to prevent it from inadvertently sliding out, yet it can be easily removed for return to the concession stand.

(3) The food service trays are 1.0” deep for easy stacking and the upper surface is textured to reduce the sliding around of the food service containers.

(4) The 0.6” by 4.0” wide slot fits most cellular phones even those with a protective guard and the side walls are about 0.50” tall, holding the phone erect for easy use or watching video of the event.

a. As an option, the slot dimensions can be adjusted if the manufacturer wants to make the slot work with all handheld devices, for example, the cell phone, the tablet, etc.

(5) The cup rests on the rim of the hole molded into the tray and is about 3.25” in diameter at the first step. The hole in the tray is 3.25” diameter and it loosely captures the cup at the 12-ounce line, preventing any spills during transportation and use.

(6) The standard cup at a concession stand will hold 16 ounces of liquid when filled to the rim and 12 ounces when filled to the first step below the rim, which is commonly done to reduce spillage during transportation back to the seat. Even if the pours are generous, there is sufficient lip height to reduce spillage.

(7) The rim of the tray is rounded and is rolled over with a lip to improve the strength so the tray does not flex even when held at one corner or one end, preventing spillage of the food or beverage as the user returns to their seat.

(8) The trays can be supplied in almost any vibrant color but the most common for stadium use are any one of the standard 14 colors, with red, black, blue, and forest green being the most popular.

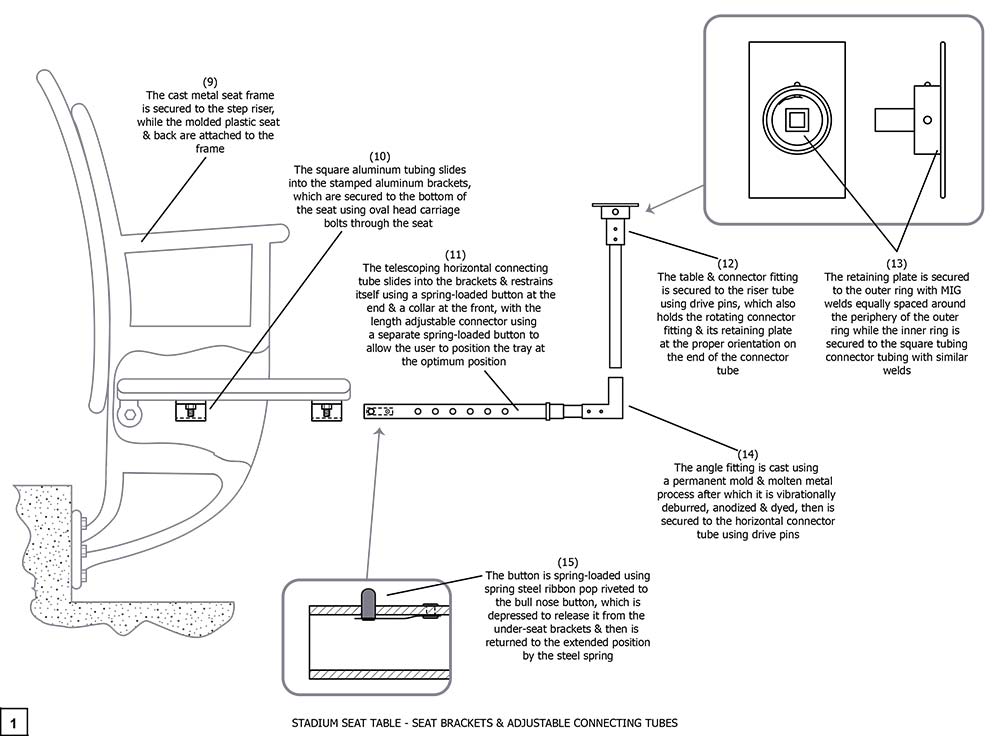

Drawing 2, Block 1: Stadium Seat Table – Seat Brackets And Adjustable Connecting Tubes

(9) The cast metal seat frame is secured to the step riser, while the molded plastic seat and back are attached to the frame.

(10) The square aluminum tubing slides into the stamped aluminum brackets, which are secured to the bottom of the seat using oval head carriage bolts through the seat. These brackets and fasteners allow retro-fitting this invention to any stadium in the country.

(11) The telescoping horizontal connecting tube slides into the brackets and restrains itself using a spring-loaded button at the end and a collar at the front, with the length adjustable connector using a separate spring-loaded button to allow the user to position the tray at the optimum position.

(12) The table and connector fitting is secured to the riser tube using drive pins, which also holds the rotating connector fitting and its retaining plate at the proper orientation on the end of the connector tube.

(13) The retaining plate is secured to the outer ring with MIG welds equally space around the periphery of the outer ring while the inner ring is secured to the square tubing connector tubing with similar welds. The outer ring’s interior surface is slotted to accept a snap ring to hold the two rings together and allow them rotate independently. The outer ring is drilled in 4 places (or more) to accept the spring-loaded rotation button mounted on the inner ring, locking them in place.

(14) The angle fitting is cast using a permanent mold and molten metal process after which it is vibrationally deburred, anodized and dyed, then is secured to the horizontal tube using drive pins.

(15) The button is spring loaded using spring steel ribbon pop riveted to the bull nose button, which is depressed to release it from the under-seat brackets and then is returned to the extended position by the steel spring.

a. Note: It is anticipated that the tray will be removed from the riser and roving operators will collect and return them to the concession stand for cleansing. After which, the fan will remove the riser tube and store it underneath the seat on a spring clip fastened to accept it. Then the fan can collapse the horizontal tube to its shortest position or remove it and store it under the seat as well, whichever they like best.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.