Tamale Machine

DESCRIPTION:

Tamales have been a food source in the Americas for centuries and date back to before the pre-Columbian era. The Aztecs, Mayas, and other American civilizations have had their own version of the tamale. Tamales were used as easily portable food and found their way on hunting trips and traveling for these indigenous peoples. A simple method of cooking corn, the tamale is thought to have originated somewhere in Central America.

In Mexico, the tamale is usually made from a dough derived from corn mix that is commonly called masa. The masa is wrapped around a filling that can vary from a meat mixtures, cheeses, salsas, roasted peppers, and many other fillings. The fillings are a matter of preference for individual tastes. The entire tamale is wrapped in either a corn husk or plantain leaves to hold the product together for cooking. Cooking the tamale is done by steaming the tamale until firm.

The traditional tamale is difficult to assemble and cook and it can be labor intensive especially for large batches. It is a favorite comfort food in Mexico and the United States and can be found in many restaurants in both countries as well as in home cooking. The difficult and labor intensive process in creating and cooking tamales creates a unique problem for many people serving tamales especially when large batches are required.

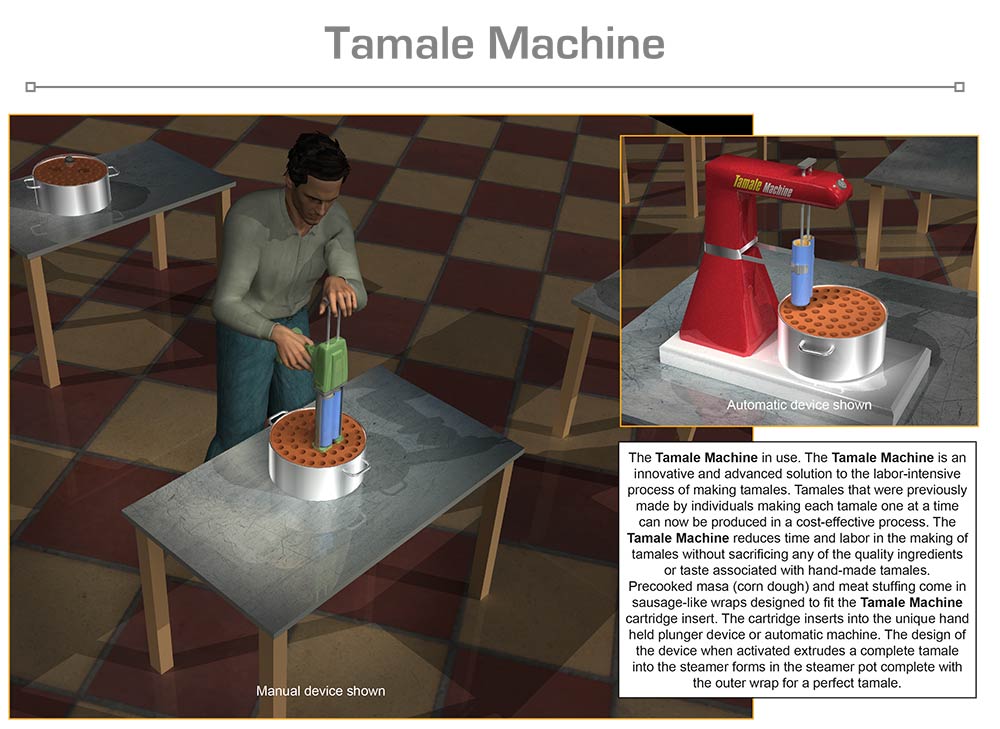

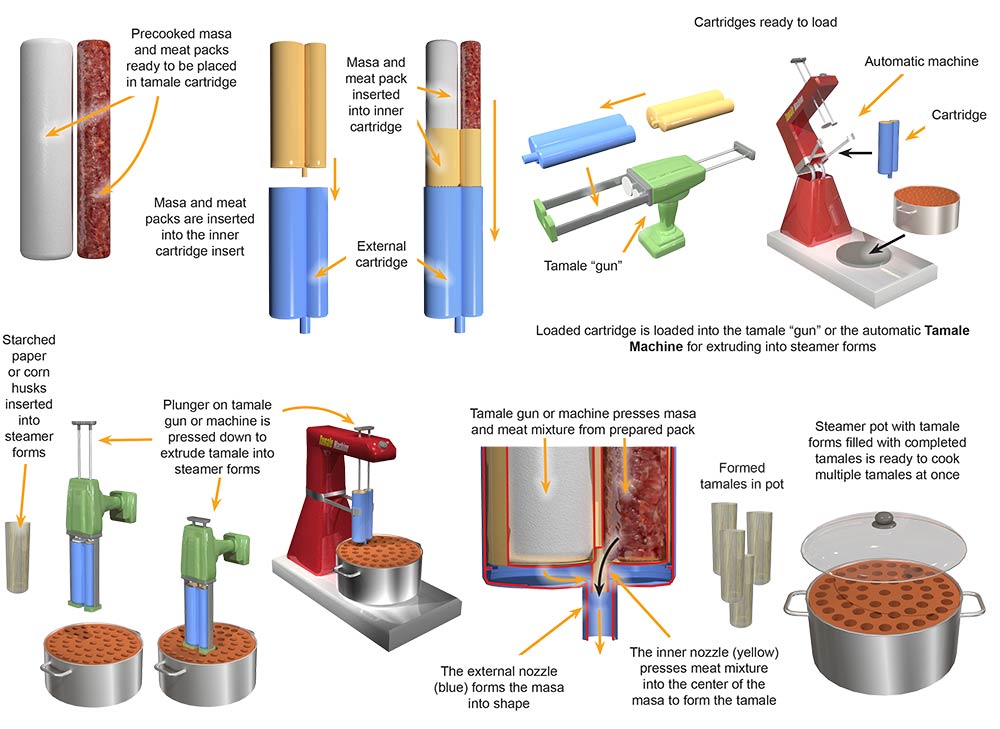

The Tamale Machine is an innovative and unique solution to the production of tamales for restaurants or home cooks wishing to reduce the time and effort in producing tamales in large batches. The Tamale Machine can be either a manual or an automatic electrically operated device. The Tamale Machine provides pre-cooked masa (corn dough) and meat in sausage like packs that are designed to fit the specially designed cartridges that fit the Tamale Machine. The packs come in a variety of flavors and meat combinations for an assortment of flavor mixtures. The dough and meat packages are placed into the inner cartridge of the Tamale Machine. The packs are pre-measured to fit exactly into the cartridge. Once the packs are installed into the inner cartridge, it slides into the outer cartridge. The combination is used to create the tamale with the utilization of the manual or automatic electric dispensers. When the packs and cartridges are loaded into the manual gun or automatic machine, a steamer pot that contains forms for the tamales is prepared. In the steamer pot forms, the starched paper or corn husks that serve as wraps to hold the tamales shape for serving are placed. The loaded tamale gun or automatic machine plunger is pressed to extrude the tamale. The design of the cartridges extrudes the masa and meat mixture to form the whole tamale.

The tamales are extruded directly into the prepared wraps that have been inserted into the steamer pot forms. The steamer pots will hold multiple tamales, and with each loading of the tamale gun or automatic machine, several tamales can be created. Once the steamer pot is filled, it can then be placed on heat for steaming with the double boiler pot that is part of the Tamale Machine system. The steamer pot has holes on the bottom to allow steam to enter the pot. The Tamale Machine saves time and is a very cost-effective system for producing tamales while maintaining the variety and taste of the traditional tamale. However, this Invention, with slight modifications can be used to produce many other types of food products such as pastries and cannolis.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Makes producing tamales cost-effective

- Pre-cooked dough and meat packs, but not limited to meat packs

- Variety of flavors and food combinations

- Blades in inner cartridge pierce the two different packs for extrusion

- Electric or manual models available

- Produces high-quality tamales, and other food combinations in quantity

- Steamer ports with tamale and various other forms

- Tamales and other food creations are created with extrusion of device

- Multiple tamales (etc.) created with one cartridge load

- Steamer system cooks many units at once

- Automated machine for producing quantity also available

- Simple operation of all components

- Constructed of sturdy materials

PRODUCT COMPONENT CLARIFICATION:

The “Tamale Machine” is an innovative restaurant product that has been designed to make assembling tamales much less labor intense. The system consists of a tamale gun that extrudes the dough and meat into parchment papers placed in the steam tray. The tamale gun fills parchment paper tubes that are about 5” long after which they are steamed to cook the dough and warm the pre-cooked meat. After making them, all of the components are machine washable for easy clean up. The system reduces the labor requirement so the tamales can be favorably priced in a restaurant environment. While restaurant applications are discussed herein, the system can be purchased and used in a home environment.

Currently, the making of tamales is a very labor filled process. The ingredients have to be sourced, typically from a Hispanic grocery store, and then laboriously processed to make the components. Then the corn husks must be soaked in water and prepared for filling. Then the corn husks are placed on the table/counter, the correct amount of masa (dough) placed on the corn husks, a piece of parchment paper placed over the masa, and the husks and masa pressed to achieve the optimum thickness. Then the parchment paper is stripped off the masa, the pre-cooked meat or cheese filling is placed on the masa, the tamales rolled and folded using the ‘diaper’ fold. After all this work, the assembled tamales are placed in a steamer pan and heated until the masa is cooked through. Then the tamales are plated, covered with picante or left plain, and served. Making these in a restaurant environment is too time consuming and makes them almost impossible to serve.

The “Tamale Machine” resolves most of these problems by providing a system that removes most of the labor requirement and brings the tamale making into the realm of profitable restaurant capability. The masa is premixed and the meat is pre-cooked. These two components are supplied to the restaurants in food grade polyamide tubes under refrigeration. The preformed parchment paper tubes are machine rolled and folded, then supplied to the restaurant as a tamale form that fits in the steam tray fabricated to make the tamales. The lower end of the parchment paper tube is closed by folding and the upper end is open to allow the extrusion gun nozzle to fit within. The extrusion gun consists of a battery powered receiver that advances the plungers into the cartridges, creating a tubular tamale that is meat or cheese filled and is about 1” in diameter with a 5/8” diameter filling center by about 5” long. This extruded tamale is located in one of many locations in the food grade plastic steamer tray and is held upright for easy cooking. The tray is retained in a stainless steel steamer pan, which is placed over a mating stainless steel pot partially filled with steaming water to cook the tamales.

In use, the operator pierces the bottom end of the bulk food tubes and then places them in the appropriate cavity in the internal cartridge. This cartridge is placed in the external cartridge with the filling nozzle fitting inside the masa nozzle. The external cartridge has a small space at the bottom to allow the masa to flow around the filling nozzle during use. Then the mated cartridges are placed in the battery powered extrusion gun after the plungers are pulled back to the ‘loading’ location. After the cartridges are inserted in the gun, the plunger is pushed forward until it contacts the top of the tube. The steamer tray is placed in the steamer pan and the tray is loaded with the parchment paper tubes. A steamer tray holds about 50 tamales per filling. Then the gun is placed over the nozzle and the trigger clicked until the first tube is filled. Then it will just take about 2 clicks to fill up the parchment tube, which is anticipated to take about 5 seconds. Assuming, that it will take one bulk food tube change to fill the tray completely, it is assumed that 50 tamales can be assembled in 7 minutes. Then the tray can be transferred to the steaming operation. Because these are fairly large tamales, 3 will make a reasonably large serving, sating normal appetites, and optimizing profit for the restaurant manager.

The system components: The tamale assembling and cooking system components are, but not limited to, as follows.

The bulk food tubes: These are supplied in premixed or pre-cooked materials in 2.5 mil food grade polyamide plastic film tubes. The food stuffs are mixed or cooked in commercial kitchens and supplied to the restaurant with the standard food order from the distributor. They are kept under refrigeration until used, meeting normal restaurant standards for cleanliness and food safety. The masa tubes are larger in diameter than the filling tubes. The filling’s texture has been optimized to retain the feel of pulled meat yet has been processed to allow optimum extrusion. Some empirical studies will have to be made to optimize the tube and cartridge volume to balance the extrusion characteristics against the tube volume so the tubes empty at the same time, reducing waste.

- As an option, the internal extrusion cartridge can be filled with masa and filling that is made on site in the restaurant and spooned into the cartridge for extrusion. The plunger plates fit snugly within the cartridge and will extrude the ‘spooned in’ material with little loss around the plate. If this type of material is used in the restaurant, wiper caps can be made available through the manufacturer’s Internet store that will prevent any loss around the plunger plate.

The parchment paper tubes: These food grade silicone treated paper are robotically formed into closed end tubes of 1” diameter by 5” long. These fit loosely in the steamer tray openings and are removed at the table by the guest just prior to consuming the tamale. The parchment paper tubes take the place of the corn husks and are sold to the restaurant by the normal paper goods supplier. The parchment paper can be steamed and retain its shape, making it a good replacement for the corn husks.

The extrusion cartridges: The internal and external cartridges are injection molded using food grade polypropylene plastic. This plastic is very durable, is highly resistant to restaurant and household chemicals, and is typically used in this type of application. The cartridges can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The internal cartridge will be supplied and a color contrasting with the external cartridge for ease of use.

These two cartridges nest together and allow the extrusion of the masa around the filling into the parchment paper tube. The internal cartridge rests on the dead stop inside the external cartridge and its nozzle extends through the external cartridge’s nozzle. The masa flows under the internal cartridge and around the filling nozzle. This extrusion technique creates a wall of masa dough around the center column of filling.

After the filling process is complete, the cartridges can be rinsed to remove most residual bulk food, and then can be placed in the commercial dishwasher for cleaning. The plastic can also be disinfected without degradation.

The steamer tray: This tray holds about 50 parchment paper tubes and will withstand steam temperatures without degradation. The tray is injection molded using food grade polypropylene plastic. The tray can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The tray fits down into the steamer pan. The walls of the steamer tray are about 0.100” thick so heat can be transferred quickly from the steam to tamale ingredients to cook them rapidly. The tray is also perforated in few places to allow the steam to flow through and cook the open end of the tamale directly, imparting the flavor associated with the manual tamale cooking process.

The steamer pan and mating steamer pot: The type 432 stainless steel clad copper center steamer pan has a perforated lower surface that lets the steam from the mating steamer pot flow up and around each of the tubes, uniformly heating the tamales and cooking the masa. The steamer tray is also perforated to allow the steam to flow up under the polycarbonate molded plastic dome lid and over the top of the tubes to steam the ends like is normally done when using manual assembly methods.

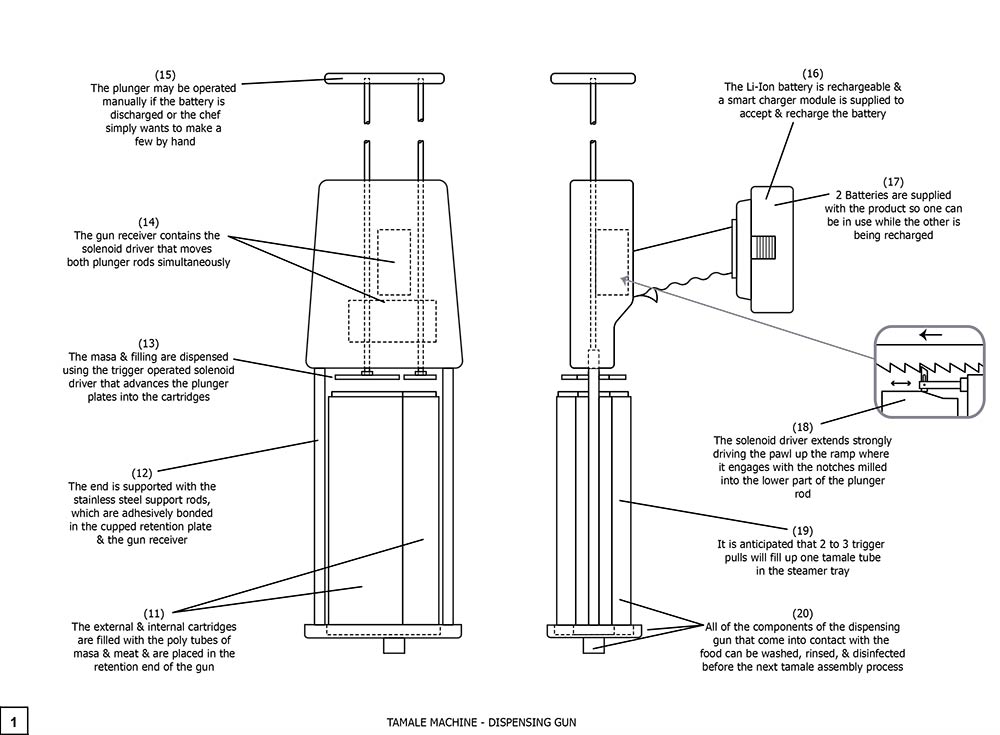

The extrusion gun: The gun is molded using food grade polycarbonate plastic. There are several sections required to make the gun and they are individually held together using stainless steel fasteners. The retention end of the gun holds the cartridges so they do not move around during the extrusion process. The retention end is attached to the gun body using type 432 stainless steel rods, which are pinned in place in the gun housing and are pinned and adhesively bonded in place in the retention end. The plunger rods hold the food grade plastic discs that are bolted to the rods. These discs compress the plastic film on the bulk food tubes and force it out of the extrusion nozzles. The upper end of the food grade stainless steel plunger rods are terminated with the manual operation plate, which are pinned and adhesively bonded in place.

The plunger rods are advanced using a ‘pawl drive’, which engages the plunger rods and forces them into the cartridges, pushing the bulk food into the dispensing nozzles. The plunger discs can be unbolted and the plunger rods removed from the gun if the need to cleaned. The solenoid pawl drive is operated using the microcontroller operated driver, which is engaged every time the trigger is pulled. The drive forces the plunger rods ahead smoothly and in a controlled fashion, giving the bulk food materials time to flow without compacting. This makes an optimum form of tamale within the parchment paper tube.

The battery is an 18V Li-Ion rechargeable unit that snaps into the base of the handle. It is capable of filling multiple trays without becoming fully discharged. The system is supplied with 2 batteries and a smart charger that allows both the batteries to remain in the charger between uses and follows a charging algorithm that enhances the overall battery life while keeping them fully charged.

The PCB for the gun is fabricated to the final assembler’s requirements in a world class contract electronic assembler facility. The standard thickness, double sided FR4 circuit board material is populated with surface mounted components where possible. Any through-hole devices are inserted after the surface mounted assembly, soldering, and cleaning. After assembly, the PCB is protected with a moisture adsorption preventive conformal coating.

- As an option: The system can be supplied with a robotic dispensing system that accepts steamer tray, which can only be installed on the robot in one orientation. The bulk food tubes are loaded in the cartridges, which are then placed in the dispensing head. The robot then identifies the number 1 tube in the steamer tray, fills it, verifies the fill with the vision system, and then moves to the next tube in the circular array, continuing on until the bulk food is depleted. The dispensing system detector lets the robot know when the bulk food is completely dispensed, stops the operation noting which tube was being filled, and flashes a light on the module to let the machine tender know they have to remove and refill the cartridges. After the bulk food cartridge is replenished, the robot goes to the next tube in the array, fills it, and moves on until all are filled, whereupon it notifies the operator that the tray needs to be removed and a new one placed in the machine. (Note: The inventor has a conceptual video of this machine for review upon request).

The Tamale Machine is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from dramatically reduced labor content, an easy to clean and maintain system, and very desirable entree item on the menu, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

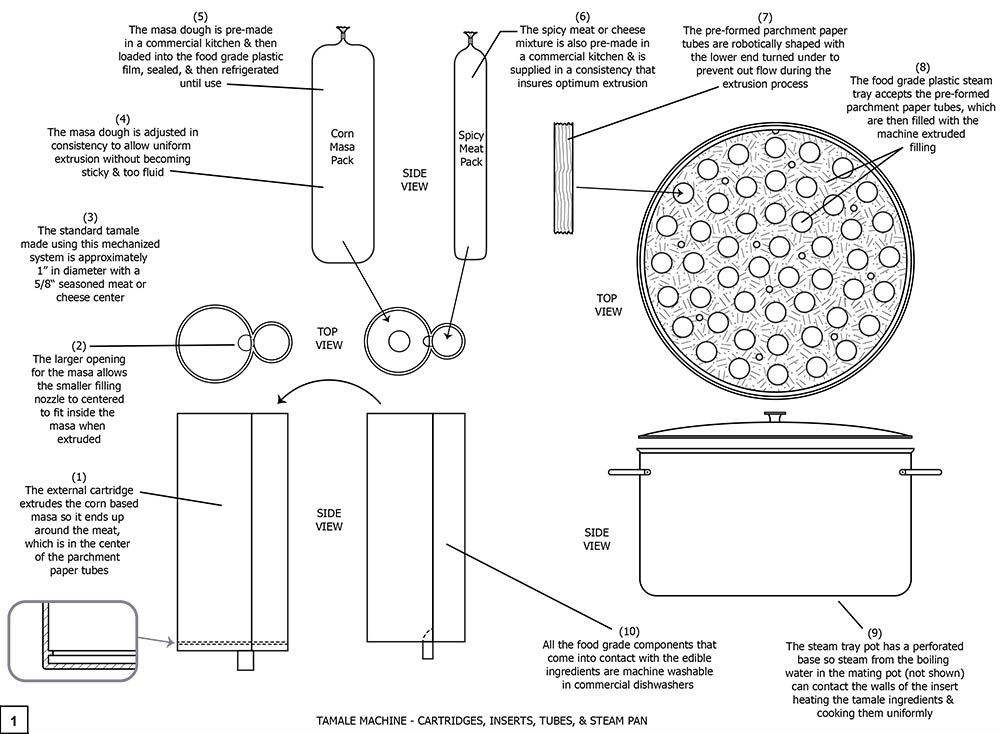

Drawing 1, Block 1: Tamale Machine – Cartridges, Inserts, Tubes, And Steam Pan

(1) The external cartridge extrudes the corn based masa so it ends up around the meat, which is in the center of the parchment paper tubes.

(2) The larger opening for the masa allows the smaller filling nozzle to fit inside the masa when extruded.

(3) The standard tamale made using this mechanized system is approximately 1” in diameter with 5/8” seasoned meat or cheese center.

(4) The masa dough is adjusted in consistency to allow uniform extrusion without becoming sticky and too fluid.

(5) The masa dough is pre-made in a commercial kitchen and then loaded into the food grade plastic film, sealed, and then refrigerated until use.

(6) The spicy meat or cheese mixture is also pre-made in a commercial kitchen and is supplied in a consistency that insures optimum extrusion.

(7) The preformed parchment paper tubes are robotically shaped with the lower end turned under to prevent outflow during the extrusion process.

(8) The food grade plastic steam tray accepts the per-formed parchment paper tubes, which are then filled with machine extruded tamale components.

(9) The steam tray pot has a perforated base so the steam from the boiling water in the mating pot (not shown) can contact the walls of the insert heating the tamale ingredients and cooking them uniformly.

(10) All the food grade components that come into contact with the edible ingredients are machine washable in commercial dishwashers.

Drawing 2, Block 1: Tamale Machine – Dispensing Gun

(11) The internal and external cartridges are filled with the poly tubes of masa and meat and are placed in the retention end of the gun.

(12) The end is supported with the stainless steel support rods, which are adhesively bonded in the cupped retention plate and gun receiver.

(13) The masa and filling are dispensed using the trigger operated solenoid driver that advances the plunger plates into the cartridges.

(14) The gun receiver contains the solenoid driver that moves both the plunger rods simultaneously. The rods remain parallel as well.

(15) The plungers may be operated manually if the battery is discharged or the chef simply wants to make a few by hand.

(16) The Li-Ion battery is rechargeable and a smart charger is supplied to accept and recharge the batteries. This charger is a 2 bay unit that plugs into the restaurant’s 120 VAC mains.

(17) 2 batteries are supplied with the product so one can be in use while the other is being recharged.

(18) The solenoid driver extends strongly driving the pawl up the ramp where it engages with the notches milled into the lower part of the plunger rod.

(19) It is anticipated that 2 to 3 trigger pulls will fill up one tamale tube in the steamer tray.

(20) All of the components that come into contact with the food can be washed, rinsed, and disinfected before the next tamale assembly process.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.