Temp-O-Vibe

DESCRIPTION:

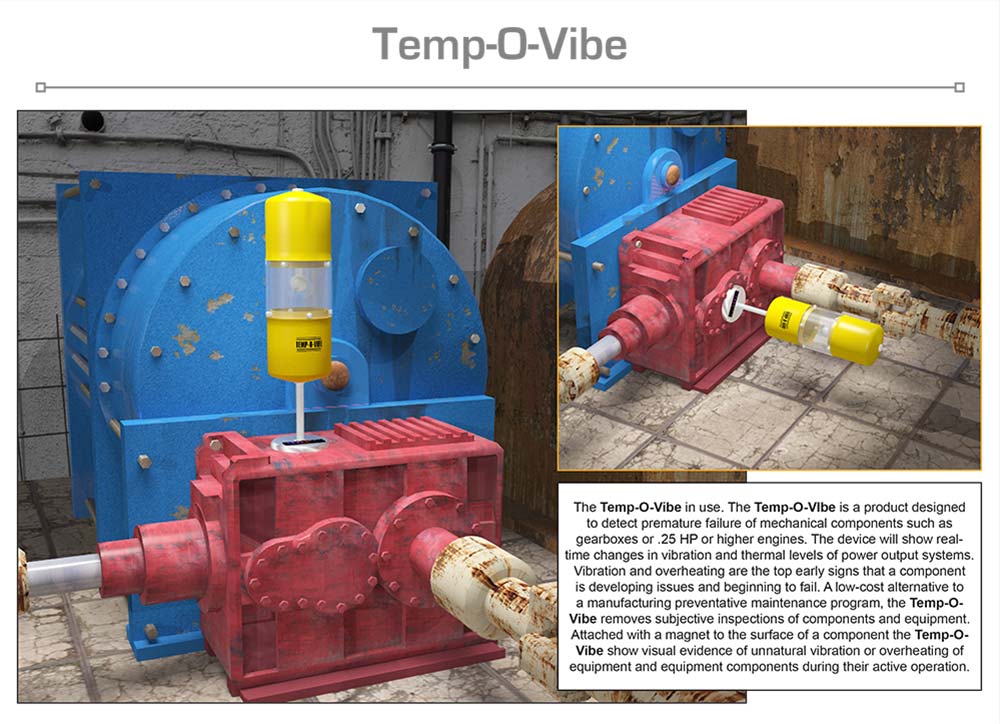

Heat and vibrations that are above normal operating levels are the early signs of premature failure of equipment. Detection of abnormal levels of these two warning signs by the Temp-O-Vibe efficiency reduces the chances of an expensive and unexpected shutdown of components. The addition of the Temp-O-Vibe to maintenance routines adds confidence to the monitoring of vital equipment and reduces the chances of unforeseen failures, loss of revenue, disruption of schedules and distressed clients.

There is no doubt the invention of the wheel is one of the most important developments in the history of civilization. The connection of the wheel to an axel is what makes the wheel a useful device. The utilization for practical purposes also requires that the wheel have bearings to turn on. The transfer of a rotating power source from one device to another usually requires that a connection is made through an axle or shaft to a wheel or gear. The relationship between the rotation point on the wheel and shaft is where the most stress and friction occurs for these two components. Friction causes heat, and the buildup of heat can create an environment that will soon become intolerable for the apparatuses to operate and will lead to premature failure. Bearings placed at the rotating points to reduce friction and provide smooth operation of the devices have greatly increased the life and efficiency of such devices. Bearings require lubrication to perform their jobs correctly and the higher the tolerances on the moving parts, the longer they will perform and more efficient they become. A loss of lubrication on a high output device can mean almost certain failure. Even a momentary loss of lubrication can damage the machine’s bearings and mean the failure of the bearing further along in time. Engines and gearboxes, when improperly serviced or not serviced at all for long periods will experience a premature failure.

Contamination of lubricants, leakage, and other variables that affect the machines ability to maintain optimum operating conditions all contribute to the premature failure of vital components that will shut down an important device. Machine manufacturers usually provide necessary guidance on machine operating conditions and keeping machines in good operating order requires good maintenance procedures. The constant monitoring of important machines and power output equipment is vital in maintaining production and optimum operating conditions for such equipment. Constant monitoring of equipment is difficult, and feedback from the machines is not always obvious for even highly trained personnel.

The Temp-O-Vibe is a unique and innovative product designed to enhance the ability to monitor and make judgments on the operating health of machines and other equipment. Power output machines such as engines and gearboxes can now have an immediate assessment of their operating conditions utilizing the Temp-O-Vibe. The Temp-O-Vibe will connect to a piece of machinery using its powerful magnet located at the base of the product. In addition to the magnet at the base, a temperature sensitive strip is positioned so that will give the operating temperature of the equipment in real time. The temperature strip will make determining the operating temperature of the selected apparatus visually fast and easy. The base features a coil spring shaft that supports a vibration detection housing. The housing is in two parts, a lower section cup and an upper section cup connected by a clear plastic cylinder. Located in the upper section cup of the Temp-O-Vibe is a steel ball that is connected to another steel coil spring shaft. The coil spring shaft is connected at the top of the upper cup section. When the Temp-O-Vibe is connected to the machinery near to internal gears or output shafts the product will detect any subtle vibrations coming from the mechanical component. The steel ball suspended from the spring coil shaft will visibly show any abnormal vibration that may be present. The Temp-O-Vibe will provide anyone monitoring and maintaining equipment that operates with gears or shafts turning at high or low speeds the ability to immediately detect any abnormal temperatures or vibrations. The ability to see problems before a catastrophic break down can save enormous amounts of time and expense.

The Temp-O-Vibe improves the monitoring capability of vital components in any operating environment. Shutdown disasters are always best avoided, and the easy visual monitoring capabilities of the Temp-O-Vibe creates unmistakable feedback from essential components. The Temp-O-Vibe decreases the chances of the unforeseen from disrupting any operation dealing with power and turning equipment.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Fits on almost any type of operating machinery

- Light-weight and easy to carry

- Allows visual inspection of equipment

- Temperature sensitive tape on base provides feedback

- Magnet attaches to machines

- Spring mounted steel ball detects vibrations

- Clear center section for visual inspection of vibration

- Simple design will last for years

- Makes maintaining equipment easy and accurate

- Waterproof, grease and oil proof

- Saves time and money on maintenance

PRODUCT COMPONENT CLARIFICATION:

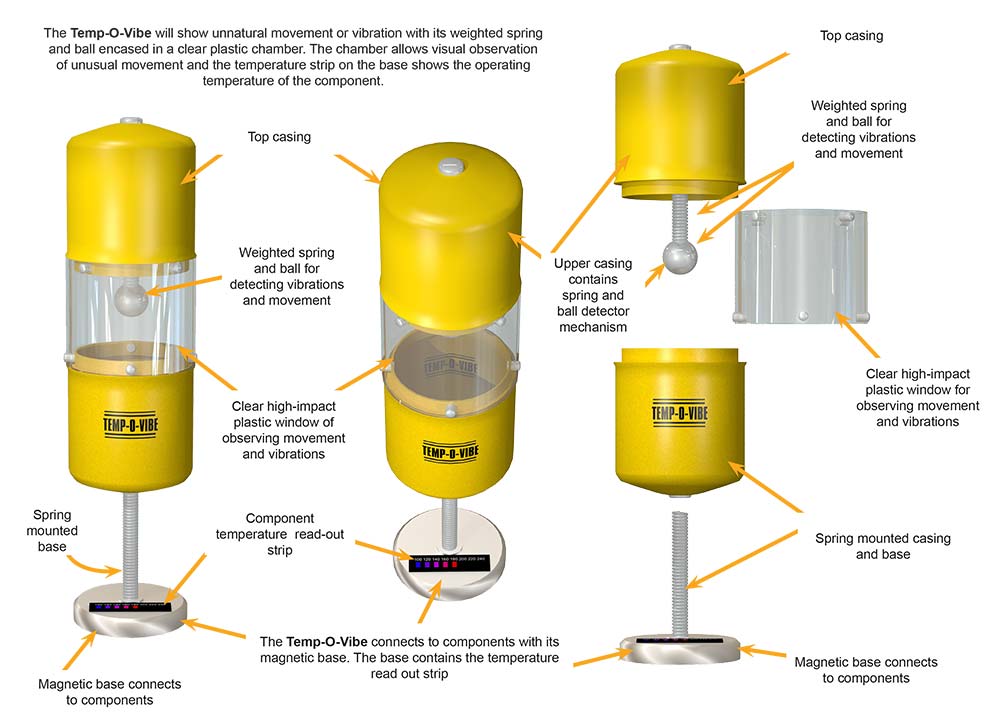

The “Temp-O-Vibe” is an innovative machine maintenance product that has been designed to allow the technician to unobtrusively observe machine vibrations and temperature history during use. The simple, yet elegant, product uses a plastic housing, a metallic base, and spring supports to observe machine’s operating temperature and any latent vibrations to catch pre-mature failure of equipment during operation. The magnetic base fastens to any ferrous machine housing and the mass vibration measuring system is engaged. The base also contains an 8 position, irreversible temperature measuring strip that monitors the machine surface upon which it has been placed. The strips are replaceable so the product can be reused for hundreds of times.

There are many variables that affect the operating conditions of rotating or reciprocating machines. They can be low on lubricants, causing premature wear of bearings, or the seals may be leaking allowing unwanted fluids to contaminate the lubricants, or allow the lubricant level to be low. When the technician is in a noisy work environment, bearing wear noise is very hard to hear. The main two indicators of a poor operating condition and the resultant premature machine failure are heat and vibration. Currently, the technician has to go around and measure the temperature of the machine housing and feel for any vibrations to determine the operating conditions of rotating or reciprocal machines. If the technician’s touch is not sensitive or calibrated, early warnings may be missed and a very costly work stoppage may result.

The “Temp-O-Vibe” resolves most of these machine wear observations by providing the technician with a simple to use, portable vibration and temperature measuring device. The durable product consists of a molded plastic 3 section housing, a spring supported spherical mass vibration monitor, and an irreversible temperature measuring strip. The device has a magnetic base, which can be placed on any ferrous motor housing or cabinet. The temperature strip measures and records the latent machine temperature, while the vibration monitor immediately allows the technician to observe the machine vibration. The translucent cylindrical window allows the user to easily observe the vibration amplitude sphere and prevents any perturbation of the measurement due to environmental conditions. After use, the technician can log their observations and over time, can build up what are acceptable limits for each machine. Any observed deviation from those levels can be investigated and any required repairs made to keep the machinery in good health and on line. The ruggedized product can even be used in outdoor environments. After use, the product can be wiped down with soap and water, dried, the temperature strip replaced, and then the product can be stored for the next use.

The “Temp-O-Vibe” is assembled from the, but not limited to, following components.

The plastic housings: These housings are injection molded using polypropylene plastic. This plastic is very durable, is highly resistant to household and workplace chemicals, is easy to clean, and is typically used in this type of application. The housings can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. The upper housing is molded with threads to accept the vibration monitor spring and the lower housing is threaded to accept the support spring. There are mating holes molded in the housing and window sections to allow securing with small stainless-steel fasteners.

The plastic window: This cylindrical window is injection molded from translucent polycarbonate plastic. This plastic is very durable, is highly resistant to drop shocks, and is typically used in this type of application. Mating holes are molded in to allow assembly to the upper and lower housings. Once assembled, part of the upper spring and the spherical ball can easily be observed from any location around the device.

The base: The base upper and lower cups are stamped from 16-gauge (0.051” thick) steel sheet. This 2-piece base accepts the support spring, the heat transfer component, and the 4 magnets. After stamping, the components are subjected to a vibrational deburring operation, are cleaned, and then nickel plated to reduce scratching and corrosion. After the components are installed, the 2 sections are joined using 4 self-tapping sheet metal screws.

- The heat transfer element: This fan shaped copper product is cut to shape on a CNC water jet machining center from 0.375” thick copper sheet. After fabrication, the copper piece is plated with 50 μinches of electroless nickel to protect the surface and prevent corrosion. The wider upper end is adhesively bonded to the interior of the upper cap, directly under the temperature strip location. When the lower lid is installed on the base, both the upper and lower surfaces of the cups are in intimate contact with the heat transfer device.

- The magnets: These 4 strong neodymium magnets are adhesively bonded into the cavities formed in the lower cup. The cavities are shallower than the magnets by 0.003” to insure the magnets contact the surface to be measured. The small gap will not materially affect the thermal measurement capability. The 0.75” diameter by 0.125” thick devices will each hold up to 9 pounds, or 36 pounds total.

The spring and ball: These commercially available components a cut to length and secured in place using stainless steel fasteners, where required. Otherwise, they are simply threaded into place and secured with a drop of thread locker. The 1.5” diameter stainless steel ball is drilled and attached to the end of the 5/8” OD upper spring and the fastener is secured with a drop of thread locker.

The temperature strips: These commercially available strips are fabricated using a special laminating process. The double-sided adhesive is bonded to the fusible material and paper. The opposite side of the adhesive is protected with silicone treated paper, which is stripped off when the strip is bonded to the target surface. The covering film protects the fusible material and is covered with a printed foil printed film with the temperature information upon it. These temperature strips have 8 windows that are originally silver in color and irreversibly change to black when the temperature is reached. After use, the strips can be removed and an unused on installed in its place to re-set the tool for the next use.

The Temp-O-Vibe is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The technician benefits from improved observation of machine temperature and vibration, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

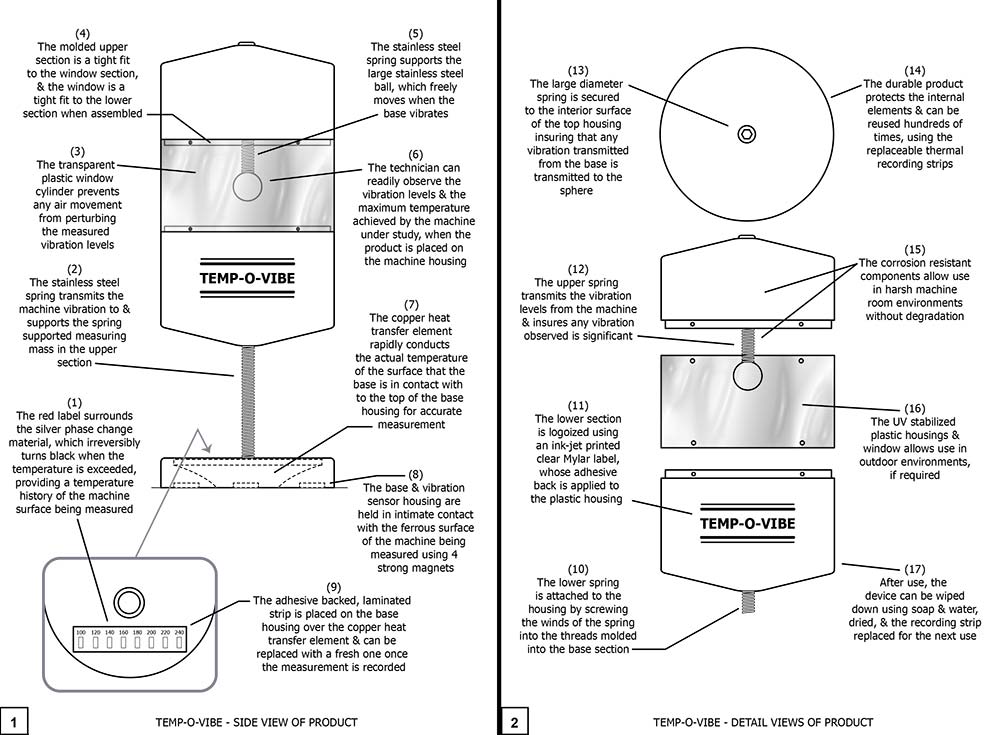

Drawing 1, Block 1: Temp-O-Vibe – Side View Of Product

(1) The red label surrounds the silver phase change material, which turns black when the temperature is exceeded, providing a temperature history of the machine surface being measured.

(2) The stainless steel spring transmits the machine vibrations to and supports the spring supported measuring mass in the upper section. The tightly wound spring is approximately 5/8” in outside diameter.

(3) The transparent plastic window prevents any air movement from perturbing the measured vibration levels.

(4) The molded upper section is a tight fit to the window section, and the window is a tight fit with the lower section when assembled.

(5) The stainless steel spring supports the large stainless steel ball, which freely moves when the base vibrates.

(6) The technician can readily observe the vibration levels and the maximum temperature achieved by the machine under study, when the product is placed on the machine housing. The product can be placed on the machinery art almost any angle and still make high quality readings possible.

(7) The copper heat transfer element rapidly conducts the actual temperature of the surface that the base is in contact with to the top of the base housing for accurate measurement. The copper block conducts heat well and quickly so the strip can ‘see’ the actual machine temperature without delay or degradation.

(8) The base and vibration sensor housing are held in intimate contact with the ferrous surface of the machine using 4 storing magnets.

(9) The adhesive backed, laminated strip is placed on the base over the copper heat transfer elements and can be replaced with a fresh one once the measurement is recorded.

Drawing 1, Block 2: Temp-O-Vibe – Detail Views Of Product

(10) The lower spring is attached to the lower housing by screwing the winds of the spring into the threads molded into the base section.

(11) The lower section is logoized using an ink-jet printed clear Mylar label, whose adhesive back is applied to the plastic housing. The printing is done using UV cured inks and is very stable, even in direct sunlight.

(12) The upper spring transmits the vibration levels from the machine and insures any vibration observed ins significant.

(13) The large diameter spring is secured to the interior surface of the top housing insuring that any vibration transmitted from the base is transmitted to the sphere.

(14) The durable product protects the internal elements and can be reused hundreds of times, using the replaceable thermal recording strips.

(15) The corrosion resistant components allow use in harsh machine room environments without degradation.

(16) The UV stabilized plastic housings and window allows use in outdoor environments, if required.

(17) After use, the device can be wiped down using soap and water, dried, and the recording strip replaced for the next use.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.