Vac Lid

DESCRIPTION:

Vacuum cleaners have been with us since the turn of the twentieth century. An appliance that developed very early in the mechanical age, the vacuum cleaner was conceived almost as soon as there was electricity to power it. There are even earlier models powered manually developed decades before the electric models. Understandably, those models had limited use and filled only specific niches in society.

The modern vacuum cleaner has established itself as a necessary machine for saving time, effort, and for effective cleaning. One of the latest innovations and embodiments of the vacuum cleaner is the development of the “shop style” vacuum cleaner usually known as the “shop vac” exhibiting larger waste containers than a typical household model. The “shop vac” has various configurations of power from a small hand held versions, handy for small jobs, vacuuming out automobiles, for instance, all the way to large industrial size models. Many models feature a wet/dry configuration, a convenient feature for removing water and damp debris from areas easily damaged by high levels of moisture.

Most people cannot justify the large, expensive industrial models for everyday use even if that use involves substantial application as would be employed in a significant cleanup of a renovation site. A “shop vac” suitable for clean-up of a site of extensive scale is usually capable of filling its five to ten-gallon receptacle rather quickly. The filing of the container rapidly presents a particular problem for anyone attempting to clean such a location. The container, once filled, has to be emptied each time it reaches capacity. Frequent clearing of the container will require the operator to make repeated trips to empty the container into a larger repository such as a dumpster or other larger waste container. This maintenance creates a highly inefficient scenario for the worker concerned with vacuuming up the area. Regardless of the size and power of the “shop vac” the limit imposed by the smaller containers in an extensive clean-up prevent the worker from performing their task in a timely and effective manner.

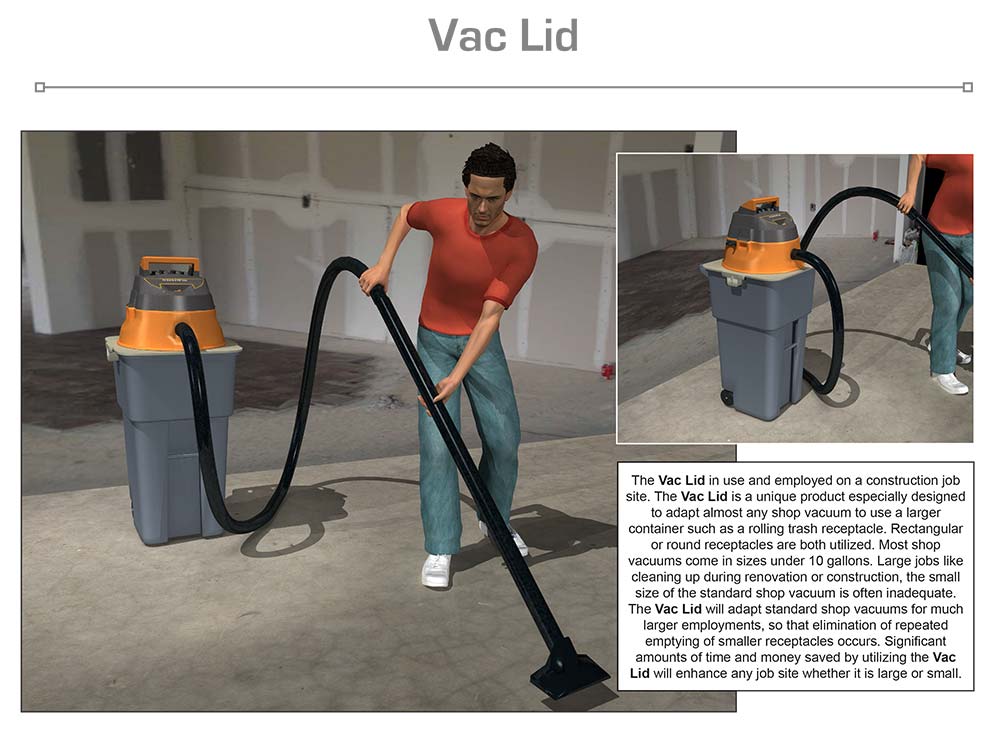

The Vac Lid is an innovative and unique solution to the issue of continuously filling the smaller containers of a “shop vac” while clean-up of a work site is in progress. The Vac Lid will adapt almost any “shop vac” to fit a larger container such as a 40 to 50- gallon waste receptacle. A simple yet ingenious single plate fits the top of the larger container. The plate is specially designed to accommodate both the upper part of the larger waste receptacle and the base of the “shop vac” once the original container of the “shop vac” is removed. The “shop vac” motor and housing are attached to the upper portion of the adapter plate. Individual blocks added to the sides of the large waste container serve as secure points to fasten the adapter plate to the receptacle. Latches located on the outside of each of the blocks attach the adapter plate to the waste container. The fasteners will also allow the entire assembly’s removal for emptying and then quickly replaced. The adapter plate features an open center section that will allow the “shop vac” to direct debris directly into the waste receptacle. The larger receptacle will permit the operator to continuously vacuum for longer periods of time without repeatedly emptying the standard containers that come with a “shop vac.” The wheels on the larger container provide leverage and ease of emptying. The Vac Lid permits the user to adapt an inexpensive “shop vac” for heavy duty jobs. The Vac Lid is valuable in saving both time and money in the process.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Adapts standard “shop vac” to larger containers

- Eliminates repeated emptying of smaller “shop vac” containers

- Inexpensive way to increase capacity of standard vacuums

- Saves time and expenses

- Simple installation

- Allows use of wheeled containers for heavy duty use

- Latches secure the assembly to top of container

- Easy removal and replacement for emptying container

- Allows user to spend more time vacuuming

- Cost effective

PRODUCT COMPONENT CLARIFICATION:

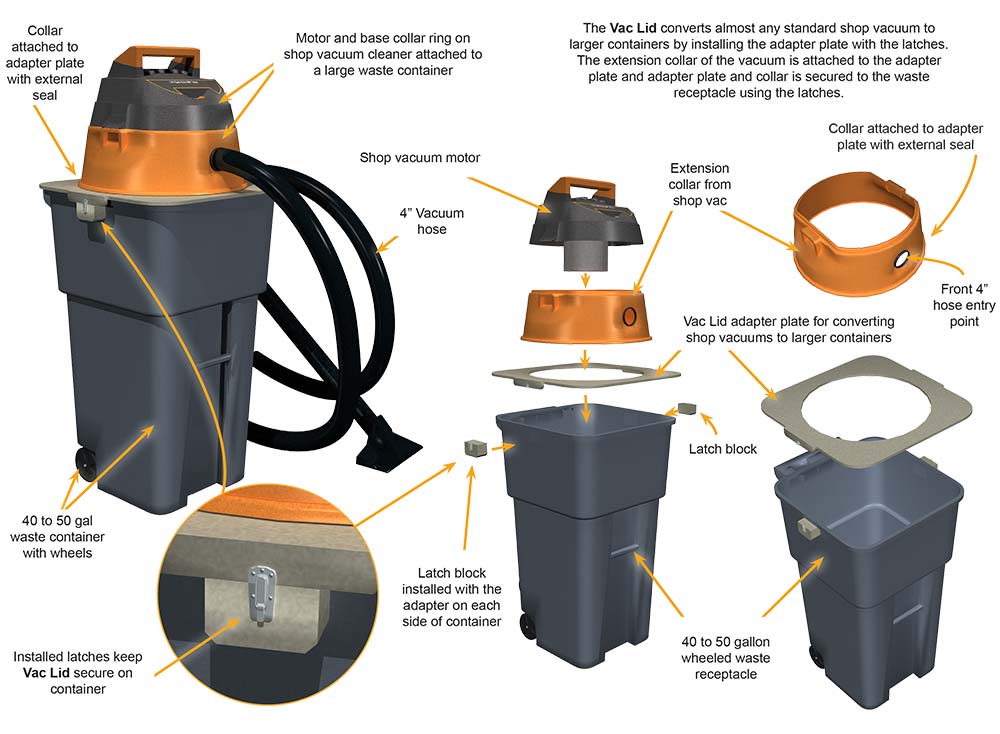

The “Vac Lid” is an innovative cleaning product that has been designed to allow the user to easily swap the suction head off of the shop vacuum and place it on this large trash can to pick up larger volumes of dust, dirt, and debris. The product consists of a heavy duty 45 gallon molded plastic trash can upon which an adapter has been attached to interface between the trash can and the specific brand of suction head. The product is also supplied with a 4” diameter by 15’ long suction hose and a few tools to make picking up materials more convenient.

Currently, the person using a standard shop vacuum to pick up larger volume materials may have to empty the collection tank of the vacuum many times before all the dust, dirt, and debris is removed from the floor or lawn. This continual emptying of the base container is very irritating and causes additional fatigue as more trips have to be made to allow the vacuum to be used after having been filled. Additionally, some debris is too large to be picked up and moved through the standard 2.5” or 1.25” diameter shop vacuum suction hose.

The “Vac Lid” resolves most of these problems by providing a 45 gallon collection container rather than a 6 to 12 gallon in a standard base, and a 4” diameter suction hose rather than a 2.5” or 1.25” one supplied in the standard shop vacuum. The system is very convenient because the suction head can be unsnapped from the standard shop vacuum and placed upon the top of the adapter, and then snapped down for use. This action is very simple and quick. After use on the invention, the suction head can be quickly unsnapped from the interface and returned to the shop vacuum for normal use.

The O.E.M. system: this system is supplied with, but not limited to, the following components.

- 45 gallon, heavy duty trash can with wheels. The sides of the trash can are ribbed to prevent drawing in and collapsing during vacuum use. The interface can be removed to allow the trash can to be used normally between vacuum uses, if desired.

- Interface base plate keyed to the trash can top surface.

- Shop vacuum interface with integral latch points. This interface is product specific with each of the most popular vacuum heads, which are detailed in the chart below.

- A 4” diameter by 15’ long molded plastic suction hose. This hose can be coiled and stored with the tools in empty trash can until the next use.

- A 4”, a 2.5”, and a 1.25” diameter molded plastic plug.

- A set of molded plastic tools that slide into the molded end of the suction hose, including a crevice tool, a 4” wide carpet nozzle, a 12” wide hard floor head with 36” wand, and an oval 4” by 36” wand.

The aftermarket system: As an option, rather than the all in one system listed above, the “Vac Lid” can be supplied in the aftermarket kit which has the capability to be fastened to the user’s trash can already on hand. The user receives, but is not limited to, the following components.

- Interface base plate keyed to the trash can top surface, i.e., either round or square top.

- Clamp blocks that are installed just under the existing trash can lid with the supplied fasteners.

- Shop vacuum interface with integral latch points. This interface is product specific with the most popular vacuum heads, which are detailed in the chart below.

- A 4” diameter by 15’ long molded plastic suction hose.

- A 4”, a 2.5”, and a 1.25” diameter molded plastic plug.

- A set of molded plastic tools that slide into the molded end of the suction hose, including a crevice tool, a 4” wide carpet nozzle, a 12” wide hard floor head with 36” wand, and an oval tipped 4” by 36” wand.

- This kit can easily be assembled onto the top of the trash can by a talented Do-It-Yourselfer, (DIY) following the supplied directions.

The interface is designed to fit a specific brand and type of shop vacuum removable head. There is no commonality between these shop vacuums in terms of size and latches, so the interface is constructed to meet that specific brand/type shop vacuum and allow easy and quick movement from the interface back to the shop vacuum and vice versa. The supplied interfaces are manufactured and supplied to fit the following shop vacuum heads, which have been listed on the Internet as the most popular.

- Ridgid WD1450

- Vacmaster VBV1210

- Craftsman 12004

- Stihl SE 62

- Shop-Vac, 3 hp, 6 gal

- Stanley SL 18130

- VacMaster VJ 507

- ArmourAll, 2 hp, 2.5 gal

- Dewalt DCV 580

The trash can: The trash can section is blow or rotationally molded from polypropylene plastic. This plastic is very durable, is highly resistant to household or shop chemicals, is UV stabilized to reduce ultraviolet degradation, and is typically used in this type of application. The wheeled trash can is supplied with reinforcing ribs so the sides will not cave in during use. The lift handle on the front and molded 6” wheels on the back allow easy movement across any terrain. The trash can is supplied with a removable, hinged lid so the container can be used as a standard trash can once the interface is removed.

The interface plate: This 0.75” thick extruded polypropylene plastic sheet is cut to shape for either round or rectangular trash cans. The O.E.M. system uses a rectangular interface plate. Both are cut to shape using a numerically controlled water jet machining center. After cutting to shape, the latch protrusions are robotically drilled to create the latch supports. Then the plates are placed on a CNC milling center to create a smoothed edge and corners and tap the holes. After fabrication, the dense EVA foam gasket is adhesively bonded to the bottom of the plate and the commercially available over center latches are installed. These latches mate with protrusions molded into the rim of the trash can.

The interface section: This raised section is blow molded using polypropylene plastic, has about a 0.100” wall thickness, and is reinforced with ribs for strength. This brand and product specific interface is blow molded to shape, including the mating latch anchor points near the upper rim that mate with the suction motor latches. The 4” inlet tube and the clearance holes for the 1/4-20 mounting screws are molded as part of this step. After fabrication, the interface section is screwed to the interface plate after a small bead of silicone rubber has been applied to the joining surfaces.

- As an option, the interface section can have a curved diverter plate molded into the side of the inlet tube, directing any dust, dirt, and debris down into the trash can so it drops out of the airstream more effectively when it slows down upon reaching the large container.

Plastic color: The individual components, (trash can, interface plate, and interface) can be supplied in almost any vibrant color, so a distinctive color may be chosen to enhance the product recognition factor, which can dramatically improve the market adoption of the product. In this case, the 3 basic sections can be molded in matching, complementary, or conflicting colors, whatever the manufacturer’s marketing department suggests.

The vacuum hose: This commercially available hose is manufactured using polyurethane rubber with spring steel wire reinforcement to prevent collapse during use. The smooth inner wall allows excellent transfer of air, dust, loose dirt, and other vacuum transferable materials. The ends of the flexible hose are terminated with polypropylene fittings that fit the interface suction tube and the supplied tools

The vacuum plugs: These commercially available plugs are injection molded using polypropylene plastic. These fit the various suction tubes that may not be used during vacuuming process. A 4”, a 2.5”, and a 1.25” plug are shipped as part of the system. Each of these has latches to lock them into the unused vacuum port.

The vacuum tools: These commercially available plugs are injection molded using polypropylene plastic. These have flared inlet areas that slip over the 4” hose termination and then are shaped at the other end for the intended use. These molded plastic tools include a crevice tool, a 4” wide carpet nozzle, a 12” wide hard floor head with 36” wand, and an oval tipped 4” by 36” wand.

The Vac Lid is designed to be aesthetic and effective in the application. The relative ease of manufacture and the inexpensive components provide good marketability for the manufacturer. The user benefits from much longer use cycles and larger size debris pickup capability, which should provide considerable market interest in the product.

The invention is illustrated in the four drawings of the essential points as explained to us in the documentation.

The product is designed to be aesthetic and effective in the application. The uncomplicated fabrication and the reasonably priced components provide good marketability for the manufacturer. The user benefits from improved usefulness and this should provide considerable market interest in the product.

The invention is illustrated in the attached drawings of the essential points as explained to us in the documentation.

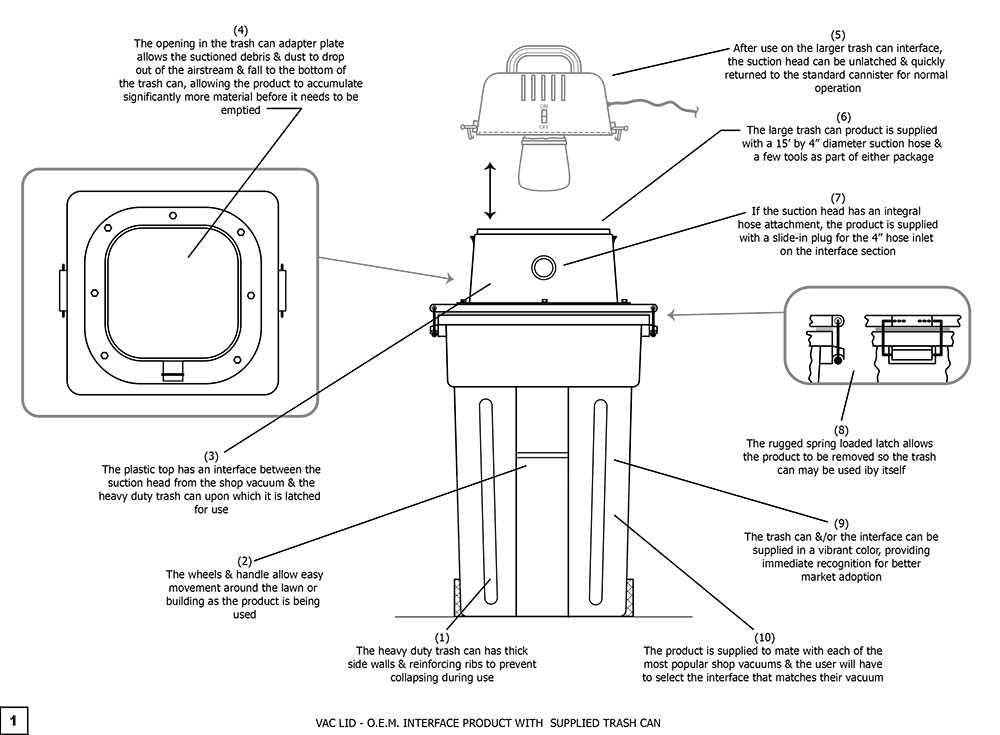

Drawing 1, Block 1: Vac Lid – O.E.M. Interface Product With Supplied Trash Can

(1) The heavy duty trash can has thick side walls and reinforcing ribs to prevent collapsing during use.

(2) The wheels and handle allow easy movement around the lawn or building as the product is being used.

(3) The plastic top ahs an interface between the suction head from the shop vacuum and the heavy duty trash can upon which it is latched for use.

(4) The opening in the trash can adapter plate allows the suctioned debris and dust to drop out of the airstream and fall to the bottom of the trash can, allowing the product to accumulate significantly more material before it needs to be emptied. To empty, the trash can to interface plate side latches are released and the interface with the suction head is removed. Now the trash can may be wheeled to the central collection site and emptied. Then the interface is re-installed.

(5) After use on the larger trash can interface, the suction head can be unlatched and quickly returned to the standard canister for normal operation.

(6) The large trash can product is supplied with a 15’ by 4” diameter suction hose and a few tools as part of either package.

(7) If the suction head has an integral hose attachment, the product is supplied with a slide-in plug for the 4” hose inlet on the interface section. Or … if the user wishes, the can use one of the smaller plugs supplied with the system and plug the inlet on the suction head.

(8) The rugged spring loaded latch allows the product to be removed so the trash can may be used by itself.

(9) The trash can or the interface can be supplied in a vibrant color, providing immediate recognition for better market adoption.

(10) The product is supplied to mate with each of the most popular shop vacuums and the user will have to select the interface that matches their vacuum.

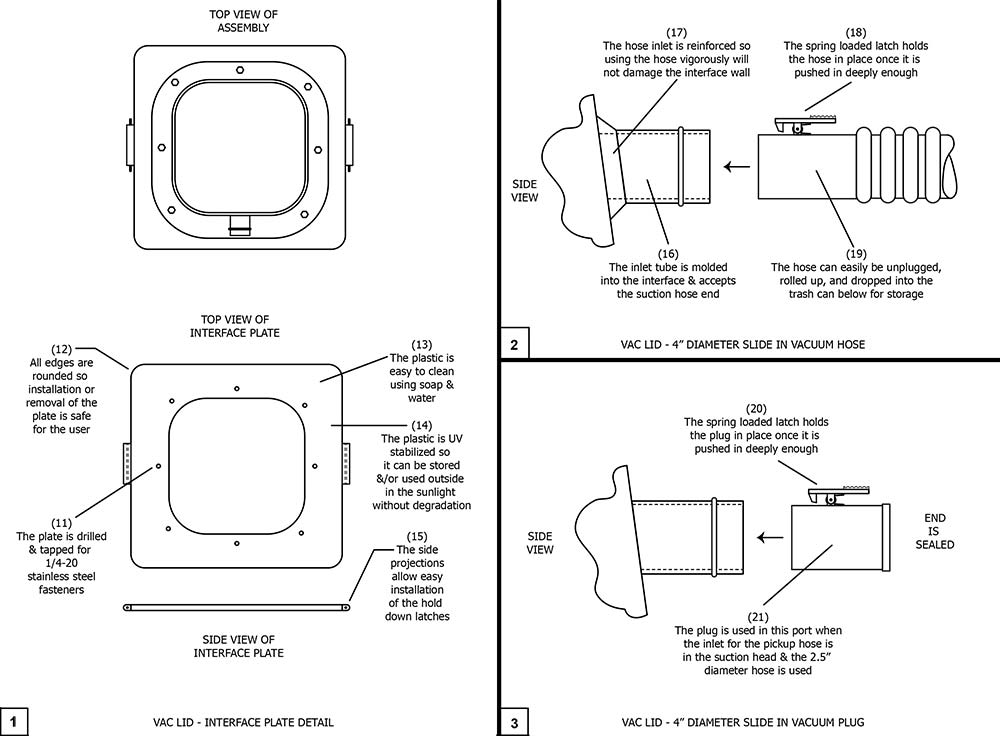

Drawing 2, Block 1: Vac Lid – Interface Plate Detail

(11) The plate is drilled and tapped for 1/4-20 stainless steel fasteners.

(12) All edges are rounded so installation or removal of the plate is safe for the user.

(13) The plastic is easy to clean using soap and water.

(14) The plastic is UV stabilized so it can be stored and/or used outside in the sunlight without degradation.

(15) The side projections allow easy installation of the hold down latches.

Drawing 2, Block 2: Vac Lid – 4” Diameter Slide In Vacuum Hose

(16) The inlet tube is molded into the interface and accepts the suction hose end.

(17) The hose inlet is reinforced so using the hose vigorously will not damage the interface wall.

(18) The spring loaded latch holds the hose in place once it is pushed in deeply enough.

(19) The hose can easily be unplugged, rolled up, and dropped into the trash can below for storage.

Drawing 2, Block 3: Vac Lid – 4” Slide In Vacuum Plug

(1) The spring loaded latch holds the hose in place once it is pushed in deeply enough.

(2) This plug is used when the inlet for the pickup hose is in the suction head and the 2.5” diameter hose is used.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.