Vessel Guidance System

DESCRIPTION:

Owning a watercraft in the United States is much more common than ever before. Once watercraft were possessions of only the wealthiest of individuals and most of those crafts were dedicated to earning money. Shipping, fishing, and warfare dominated the boating environment almost exclusively. Few persons used boats and watercraft for pleasure before the 20th century. The boats that were used for pleasure were usually small sailing vessels or rowboats.

The introduction of the internal combustion engine, when utilized to power a watercraft, revolutionized the way boats and watercraft were used. The recreational use of boats and personal watercraft has expanded into an enormous market since those earlier times.

Powerboats and personal watercraft of every description are now used every day on almost any body of water large enough to handle them. As a recreational activity, there are more than 75 million participants involved in on-the-water boating every year in the United States alone. Almost 17 million boats of all types exist in the country today and that number is growing. Recreational water sports are an enormous economical factor in the economy of the country and it has a tremendous effect on employment. It is estimated that more than 28 billion dollars in wages is paid out every year in relation to boating and other water sports.

Boating as with any other outdoor water activity has the issue of storing and docking the watercraft when not in use. Many of the boats or watercraft are stored out of the water on trailers or in boathouses and docks. Trailers are used to store and transport vessels behind vehicles and boat lifts are used for storage, and other docking systems are utilized for out of the water storage at permanent locations. Along with these systems comes the issue of loading and unloading a craft from its particular means of transport or storage. Docking a boat whether onto a trailer or a permanent docking system can be a difficult problem especially when weather issues come into play. Wind can cause havoc when trying to get a boat onto a trailer or lift. Out of necessity the trailer or lift is situated underwater to get the boat above it for removal from the water. Getting a boat in exact position for removal from the water is not easy even when everything goes correctly. The trailer is next to impossible to see even in good light. Boaters returning to the boat ramp in the evening find that the light is very limited and that can cause issues with getting the boat lined up correctly and the weather is often not very cooperative with winds and other issues. Floating boat lifts, and stations can present similar situations when handling a boat.

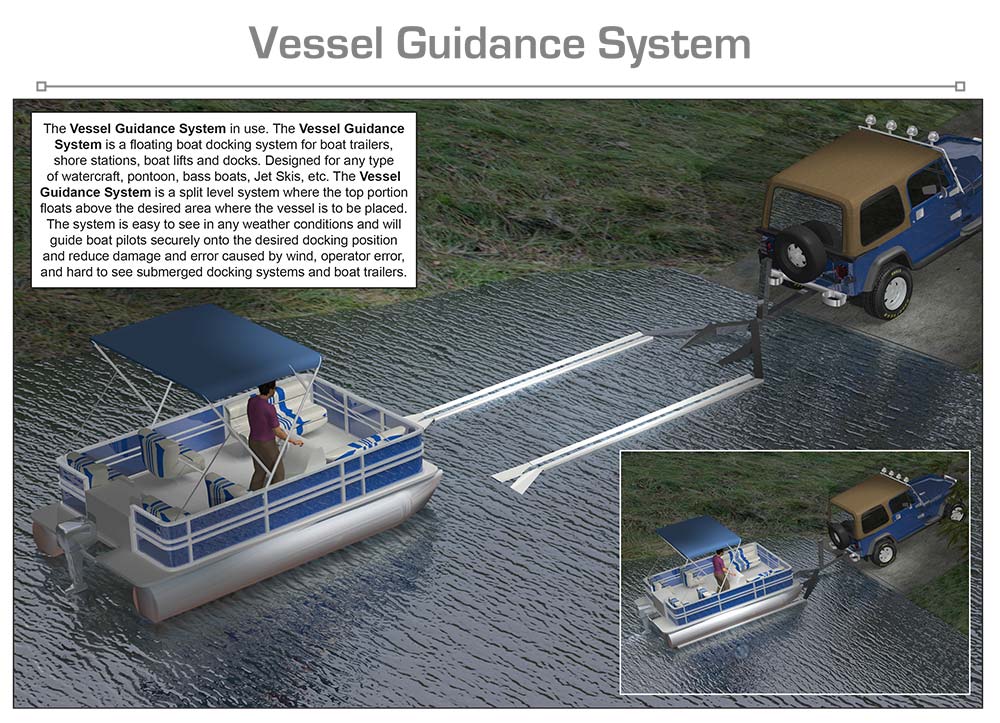

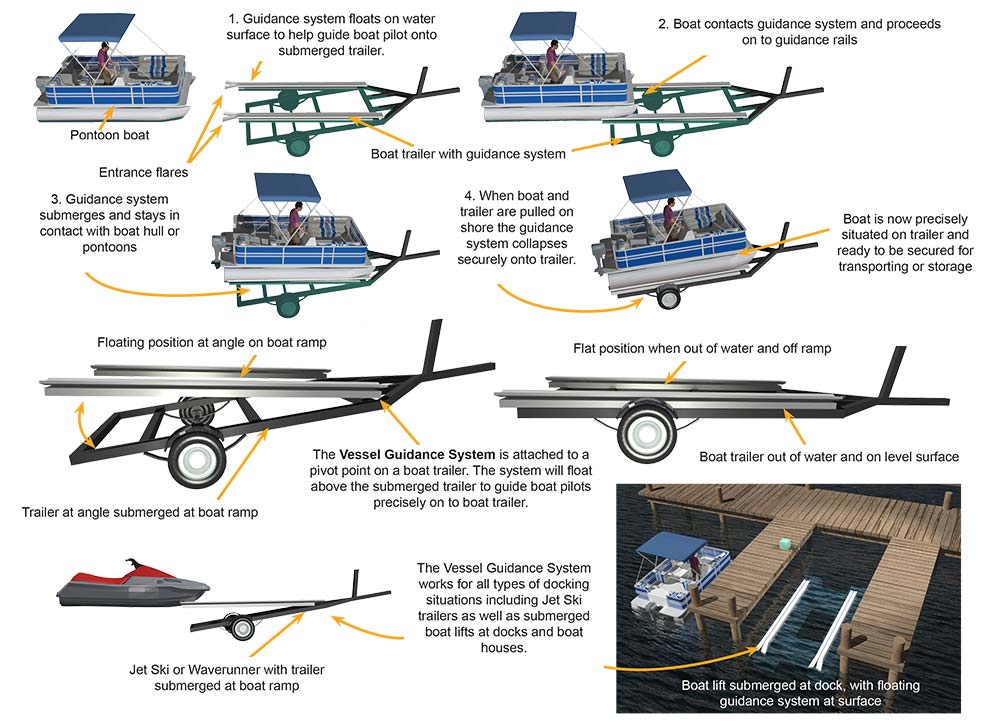

The Vessel Guidance System is a unique and inventive solution to the difficulties of guiding a boat onto a trailer or other docking system. The product is offered as either a built-in system from the manufacturer or an add-on to an existing trailer or docking arrangement. Consisting of a split floating mechanism, the Vessel Guidance System floats above a submerged trailer or boat lift and offers a physical target for the boat pilot to align their vessel. Available for pontoon boats, single hulls, and personal watercraft the floating guidance rails provide a highly visible means of aligning the vessel to the desired position. The boat is physically driven onto the floating aligning railings of the Vessel Guidance System. An entrance mouth flare is provided on each railing to aid in guiding the vessel onto the rails. Electronic aids can be added as an identifier to aid in alignment. The floating railings will be pushed under the hull or pontoons of the vessel and stay in contact with the boat keeping it in alignment with the dock or trailer. Once the vessel is fully in place, the trailer can be pulled out of the water or the lift can be operated. The floating railings will pivot down on top of the trailer or contact the docking system with the watercraft still on top of them. The craft will be perfectly situated on the trailer or docking system ready for the next launch.

SPECIFIC, UNIQUE FUNCTIONS OF INVENTION:

- Aligns vessels for loading on trailers or docking systems

- Available as manufactured built-ins or retrofitted to existing systems

- Split-floating mechanism for multi-hull or single hull vessels

- Flared entrance for receiving vessel

- System has extendable features for loading in windy conditions

- Either side can extend out relative to the other side.

- Electronic versions for alignment feedback available

- Pivoting system for loading and unloading

- Works on boat lifts and other docking systems

- Works with Pontoon boats

- Works with single hull vessels and personal watercraft

- Great benefit when loading and unloading in unimproved areas

PRODUCT COMPONENT CLARIFICATION:

The “Vessel Guidance System” is an innovative boating product that has been designed to allow easy loading of the boat onto the trailer. The product is a hinged bunk that floats on the surface of the water and guides the boat onto the bunk(s) in the correct orientation so it optimally rests upon the trailer as it is pulled from the water after loading. The floating bunk(s) and guides also make launching of the boats easy. The hinged metal, foam, and wood bunk(s) can be installed on the existing trailers or can be shipped as an OEM product.

- While the emphasis is on pontoon boats in this document, the product works equally well with standard hulled boats, personal watercraft, jet skis, or almost any watercraft requiring a trailer.

- The product will work effectively on hydro-style lifts where the product is hinged near the front of the ‘U’ shaped dock opening and the guides/bunks float partially submerged in the dock well of the air lift mechanism.

- The leading edge of the product can also be attached to the front of the well in the dock, or be attached to the dock itself, or can even be attached the bank of the lake, river or ocean. The guides and bunks float on the surface to restrain the boat between uses.

- The head of the product can be secured to the lake bed and the product stored below water level until it is needed for use. Then the guides and bunks can be released to float to the surface to hold the boat in place until the boat storage is no longer required, whereupon it can be re-submerged and stored until the next use.

Currently, as the pontoon, or any other boat, approaches the trailer to be extracted from the water after use, the angle of approach, the sideways push by the wind and water, or just the poor driving by the operator can cause the loading to be affected severely. This can translate into multiple attempts to load causing excess wear on the boat and trailer, a backup in loading for other owner/operators on the ramp, and a general irritant to a generally good boating experience. Then, if the operator finally gets the boat on the trailer, it may be so off center that it cannot be winched into place, causing additional problems in trailer imbalance and tire loading, if the operator decides to tow without correcting the problem. These issues can lead to tire failure, whipping, and highway accidents, which can be injurious or even deadly to the operator or passengers.

The “Vessel Guidance System” resolves most of these problems by allowing the hinged guides and bunks to float on the surface of the water, guiding the pontoon boat ‘logs’ onto the bunks in the proper orientation so the boat loads optimally each and every time, without drama or fuss. If the operator can get the nose cone section into the guides and the boat angle less than or equal to 30° from normal, the boat will end up latched into the nose stop and be centered on the bunks. This will result in the optimal loading of the trailer as it is pulled up the launching ramp.

The basic trailer: The trailer is the same as a normally fixed bunks trailer. It is a single axle trailer for most pontoon boats up to 20’ in length and a tandem axle trailer for larger boats. The typical dual axle trailer is shown in this document and consists of, but is not limited to, the following components.

- Two 3,500-pound axle assemblies with sealed bearings and 13” diameter, D range radial tires.

- The trailer has a 5,500-pound carrying capacity.

- 4” box frame with baked on powder coat finish.

- The frame bow and stern sections are reinforced with 5 cross members tying the side members together.

- A 2” ball hitch coupler with lockable latch.

- A 2,000-pound dual wheel, swing away tongue jack.

- A front-loading winch stand with steps, handrail, carpeted and cushioned stop, with latch.

- Custom steel fenders, (not shown for clarity).

- LED lighting in protective cages to limit damage.

- The trailer is equipped with all required D.O.T. equipment, lighting, hitch chains, and boat tie downs for USA and Canadian use.

The hinged bunks: The hinged bunks use 0.50” thick cold rolled steel plate which is formed at the factory into the hinge. The hinge is then pinned with a 0.75” diameter hardened steel bolt that is heated and headed using a hydraulic press to insure it does not come out during use. The bunk support is manufactured using thick wall 1.50” square tubing into a ‘Y’ structure, which is reinforced using 0.25” thick cold rolled steel plate cut into triangles on a water jet machining center. The lower rod of the ‘Y’ support, fits down into a notched 4” thick wall tubing mounted on a sliding plate, allowing for bunk width adjustments from 96” to 102” to match common pontoon log widths on the boats. After fabrication of the bunk support, it is securely welded to the hinge plate on all joining surfaces. As a final step, all steel components are powder coated and thermally cured for fresh water trailer use.

- As an option: the bunks can be supplied with a rod near the aft end. These angled rods swing up and keep each bunk straight while reducing the twisting moment on the hinge assembly when the boat impacts the guides. They raise and lower without binding once they are adjusted properly. These rods are 1” diameter steel tubing and have 0.375” nuts welded within. Each end of the rod has a 3/8-22 threaded bolt with a corrosion resistant ball joint rod end screwed into it. These rods are capable of resisting forces of up to 3,000 pounds each during use.

The wooden bunks: The bunks are pressure treated 2 X 4 that are cut to length and then covered with marine grade carpet. This 18-ounce per yard, UV stabilized carpet is manufactured using Olefin fiber and with the rubber backing is approximately 0.25” thick. The carpet is glued onto the front surface, wrapped around the edges of the 2 x4, and then stapled using stainless steel staples for reinforcement. After covering, the bunks are screwed onto the ‘Y’ shaped support using 0.25” diameter, stainless steel lag bolts. As an option, other materials may be substituted should they prove to be more effective.

The guides: The aft end of the bunk has the injection molded PVC plastic guides attached using 0.25” diameter, stainless steel lag bolts. These angled guides are higher than the bunks and, being white, are easy to spot on the water for targeting purposes. The guides direct the nose cone section and the skeg on the pontoon log onto the bunks as the boat is driven up onto the trailer.

The buoyant foam: The aft end of the guides and bunk assembly are made buoyant through the use of closed cell EVA foam that is molded to fit in and around the ‘Y’ shaped bunk supports. Enough foam is added to allow the bunk and guide assembly to float with about 1” of the bunk lifted out of the water. After determination of the amount of EVA foam blocks required, they are adhesively bonded in place using waterproof adhesive.

The Vessel Guidance System is designed to be aesthetic and effective in the application. The relative ease of manufacture and the moderately inexpensive components provide good marketability for the manufacturer. The user benefits from dramatically improved loading and unloading of the boat onto the trailer, which should provide considerable market interest in the product.

The invention is illustrated in the following drawings of the essential points as explained to us in the documentation.

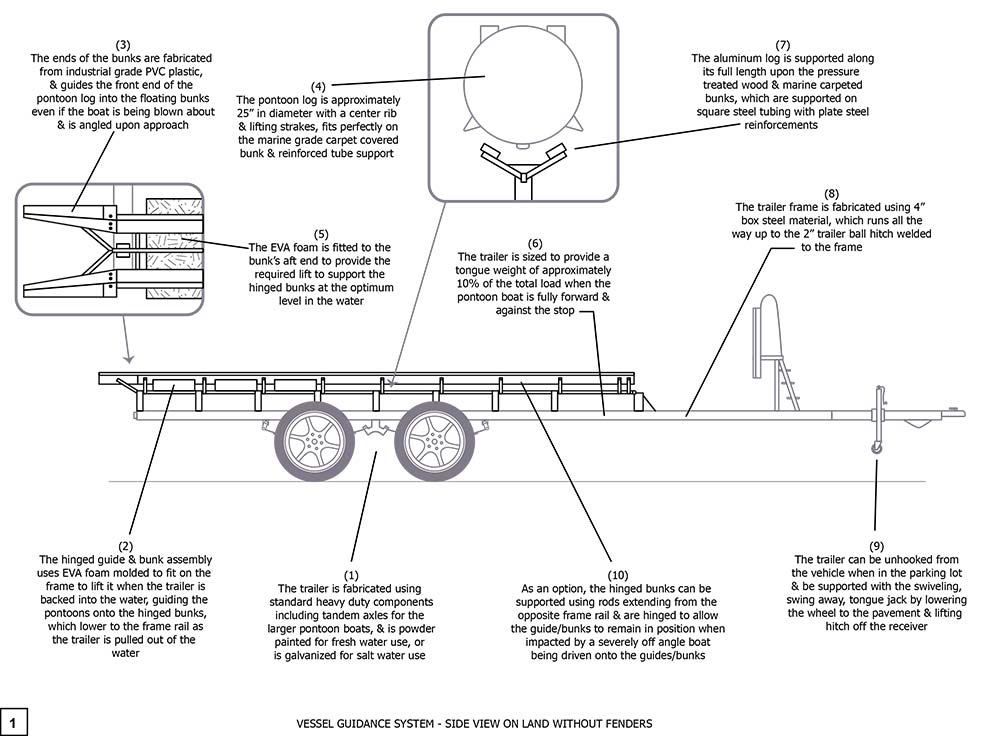

Drawing 1, Block 1: Vessel Guidance System – Side View On Land Without Fenders

(1) The trailer is fabricated using standard heavy-duty components including tandem axles for larger pontoon boats and is powder painted for fresh water use, or galvanized for salt water use.

(2) The hinged guide and bunk assembly uses EVA foam molded to fit on the frame to lift it when the trailer is backed into the water, guiding the pontoons onto the hinged bunks, which lower to the frame rail when the trailer is pulled out of the water.

(3) The ends of the bunks are fabricated from industrial grade PVC plastic and guides the front end of the pontoon log into the floating bunks, even if the boat is being blown about and is angled upon approach.

(4) The pontoon log is approximately 25” in diameter with a center rib and lifting strakes, fits perfectly on the marine grade carpet covered bunk and reinforce tube support.

(5) The EVA foam is fitted to the bunk’s aft end to provide the required lift to support the hinged bunks at the optimum level in the water.

(6) The trailer is sized to provide a tongue weight of approximately 10% of the total load when the pontoon boat is fully forward and against the stop.

(7) The aluminum log is supported along its full length upon the pressure treated wood and marine carpeted bunks, which are supported on the square steel tubing with plate steel reinforcements.

(8) The trailer frame is fabricated using 4” box steel material, which runs all the way up to the 2” trailer ball hitch welded to the frame.

(9) The trailer can be unhooked from the vehicle when in the parking lot and be supported with the swing away, tongue jack by lowering the wheel to the pavement and lifting the hitch off the trailer.

(10) As an option, the hinged bunks can be supported using rods extending from the opposite frame rail and are hinged to allow the guide/bunks to remain in position when impacted by a severely off angle boat being driven onto the guides/bunks.

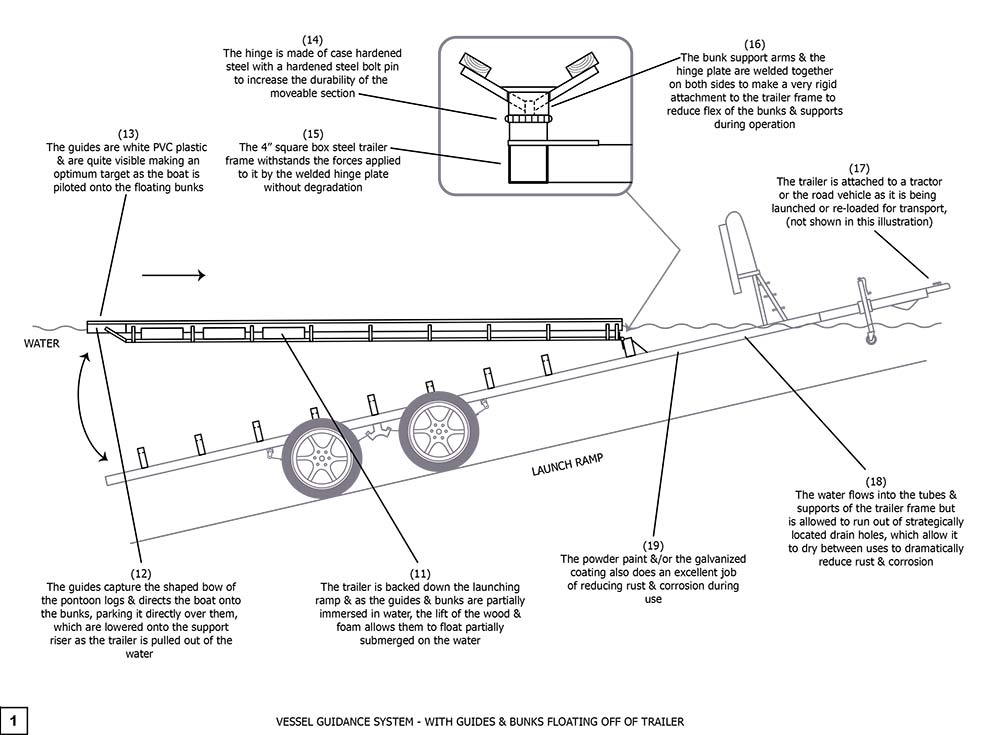

Drawing 2, Block 1: Vessel Guidance System – With Guides And Bunks Floating Off Of Trailer

(11) The trailer is backed down the launching ramp and as the guides and bunks are partially immersed in water, the lift of the wood and foam allows them to float partially submerged on the water.

(12) The guides capture the shaped bow of the pontoon logs and directs the boat onto the bunks, parking directly over them, which are lowered to the support riser as the trailer is pulled out of the water.

(13) The guides are white PVC plastic and are quite visible making an optimum target as the boat is piloted onto the floating bunks.

(14) The hinge is made of case hardened steel with a hardened steel bolt pin to increase the durability of thee movable section.

(15) The 4” box steel trailer frame withstands the forces applied to it by the by the welded hinge plate without degradation.

(16) The bunk support arms and the hinge plate are welded together on both sides to make a very rigid attachment to the trailer frame to reduce flex of the bunks and supports during operation.

(17) The trailer is attached to a tractor or the road vehicle as it is being launched or re-loaded for transport, (not shown in this illustration).

(18) The water flows into the tubes and supports of the trailer but is allowed to run out of strategically located drain holes, which allow it to dry between uses to dramatically reduce rust and corrosion.

(19) The powder paint and/or the galvanized coating also does an excellent job of reducing rust and corrosion during use.

Although a single embodiment of the invention has been illustrated in the accompanying drawings and described in the above detailed description, it will be understood that the invention is not limited to the embodiment developed herein, but is capable of numerous rearrangements, modifications, substitutions of parts and elements without departing from the spirit and scope of the invention.

This document has been prepared for the manufacturer’s elucidation. The manufacturer’s decision makers should consider this product for licensing (providing intellectual property protection for their sales of the product in return for a royalty payment for a period of years) or an outright purchase of the patent for a negotiated fee. The inventor and his team are standing by to consider offers for licensing or outright purchase of the patent.